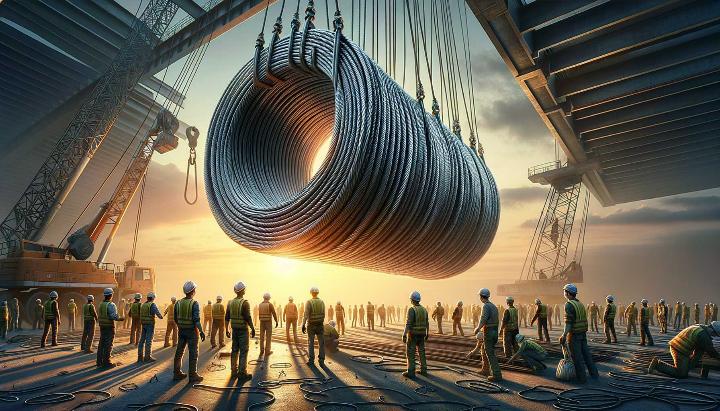

Have you ever wondered why some heavy-duty lifting operations seem effortless while others struggle? The secret lies in the unsung hero of industrial rigging: the endless wire rope sling. These remarkable tools are revolutionising the way industries tackle their most challenging lifting tasks, and for good reason.

Imagine a world where your lifting operations are not just safer, but also more efficient and versatile. That's the reality when you discover the perfect endless wire rope sling for your needs. At iRopes, we've seen firsthand how the right sling can transform a business's operations, from construction sites to shipping yards and beyond.

In this post, we'll dive deep into the world of endless wire rope slings, exploring their unique construction, the critical importance of sling diameter, and the myriad of customisation options available. Whether you're a seasoned rigging professional or new to the game, you'll discover how iRopes' expertise in manufacturing customised endless wire rope slings can elevate your lifting operations to new heights.

Ready to unlock the full potential of your industrial lifting tasks? Let's embark on a journey to find your perfect endless wire rope sling partner.

Understanding Endless Wire Rope Slings

When it comes to heavy-duty lifting applications, endless wire rope slings are the unsung heroes of the rigging world. These robust and versatile tools are essential for safely handling loads in various industrial settings. Let's dive into the world of endless wire rope slings and discover why they're a go-to choice for many professionals.

Types and Construction of Endless Wire Rope Slings

Endless wire rope slings, also known as grommet slings, are crafted from a single continuous strand of wire rope. This unique construction sets them apart from other sling types and offers several advantages. Imagine a seamless loop of steel cables, meticulously woven together to create a strong and flexible lifting solution.

The manufacturing process involves carefully splicing the wire rope ends together, creating a seamless connection that distributes the load evenly across the entire sling. This construction method results in a sling with superior strength and durability compared to single-leg wire rope slings or synthetic web slings.

Applications and Advantages of Endless Wire Rope Slings

Endless wire rope slings shine in heavy-duty industrial lifting applications. Their versatility and strength make them ideal for a wide range of tasks, from construction and manufacturing to shipping and offshore operations. But what sets them apart from other sling types?

- Increased load capacity: Grommet slings offer extra capacity for the same rope diameter, allowing you to lift heavier loads safely.

- Excellent flexibility: The continuous loop design provides superior flexibility, making it easier to handle and position loads in tight spaces.

- Reduced headroom requirements: Endless slings require less overhead clearance, making them perfect for low-ceiling environments or confined spaces.

- Even load distribution: The seamless construction ensures that the load is distributed evenly across the entire sling, reducing stress points and increasing overall safety.

Have you ever struggled with a rigid sling that just wouldn't cooperate? Endless wire rope slings offer the perfect solution, combining strength with flexibility to make your lifting tasks smoother and safer.

Safety and Capacity Calculations for Endless Wire Rope Slings

Safety is paramount when working with any lifting equipment, and endless wire rope slings are no exception. To ensure safe operation, it's crucial to understand the safety factor and capacity calculations associated with these slings.

Always apply a safety factor of 5 when calculating the working load limit for endless wire rope slings. This means the sling's breaking strength should be at least five times the maximum load you plan to lift.

To calculate the sling's capacity, you'll need to consider factors such as the wire rope diameter, the number of parts in the sling, and the angle at which the sling is used. Don't forget to factor in any environmental conditions that might affect the sling's performance, such as extreme temperatures or exposure to chemicals.

Regular inspections are crucial for maintaining the safety and integrity of your endless wire rope slings. Remember the 3-6 rule: inspect your slings for visible damage every three months and perform a thorough examination every six months. By following these guidelines and using proper calculation methods, you'll ensure that your endless wire rope slings continue to perform safely and efficiently in even the most demanding applications.

Exploring the significance of wire rope sling diameter

When it comes to selecting the right endless wire rope sling for your lifting needs, understanding the importance of wire rope sling diameter is crucial. As a seasoned rigging expert, I've seen firsthand how this seemingly small detail can make a world of difference in the safety and efficiency of lifting operations.

Understanding Wire Rope Sling Diameter

Wire rope sling diameter is more than just a measurement; it's a key factor in determining the strength, flexibility, and overall performance of your sling. Picture this: you're standing in a warehouse, surrounded by spools of wire rope in various sizes. Each diameter represents a unique balance of strength and flexibility, waiting to be harnessed for your specific lifting needs.

The diameter of a wire rope sling directly impacts its load capacity and performance. As a general rule, a larger diameter typically means a higher load capacity, but it also results in a stiffer sling. On the flip side, a smaller diameter offers more flexibility but at the cost of reduced strength. It's a delicate balance that requires careful consideration based on your specific application.

The Importance of D/d Ratio

Have you ever heard of the D/d ratio? It's a crucial concept in the world of wire rope slings that often gets overlooked. The D/d ratio refers to the relationship between the diameter of the object around which the sling is bent (D) and the diameter of the wire rope itself (d). This ratio plays a significant role in determining the efficiency and safety of your sling.

- Higher D/d ratio: Results in less stress on the wire rope, leading to increased efficiency and longer sling life.

- Lower D/d ratio: Causes more stress on the wire rope, potentially reducing its strength and lifespan.

For optimal performance and safety, industry standards recommend a minimum D/d ratio of 20:1 for most applications. However, this can vary depending on the specific requirements of your lifting task.

Measuring Wire Rope Diameter Correctly

Accurate measurement of wire rope diameter is essential for selecting the right sling and ensuring safe operations. I remember a time when a colleague's eyeball estimate led to a near-miss incident. Trust me, you don't want to learn this lesson the hard way!

Always use calipers for precise wire rope diameter measurements. Avoid using tape measures or eyeball estimates, as these can lead to inaccurate results and potentially dangerous situations.

To measure correctly, place the wire rope between the jaws of the caliper, ensuring you're measuring across the widest part of the rope. Take multiple measurements at different points along the rope's length and average the results for the most accurate reading.

Remember, a reduction in wire rope diameter can indicate wear or damage. Regular inspections and measurements are crucial for maintaining the safety and integrity of your wire rope slings.

At iRopes, we understand the critical role that wire rope sling diameter plays in lifting operations. That's why we offer a wide range of diameters to suit various applications, ensuring you always have the right tool for the job. Have you considered how the diameter of your current wire rope slings might be affecting your operations? It might be time for a reassessment to optimize your lifting efficiency and safety.

Customization Options for Endless Wire Rope Slings

When it comes to lifting solutions, one size certainly doesn't fit all. That's where the magic of customization comes into play, especially with endless wire rope slings. At iRopes, we've seen firsthand how tailored solutions can make a world of difference in efficiency and safety across various industries.

Types and Materials of Endless Wire Rope Slings

The backbone of any endless wire rope sling is, of course, the material it's made from. Let's explore some of the most common options:

- Galvanized steel: Offers excellent corrosion resistance, perfect for outdoor applications or marine environments.

- Stainless steel: Ideal for food processing or pharmaceutical industries where hygiene is paramount.

- Carbon steel: Provides high strength and durability for general-purpose lifting tasks.

Each material brings its own set of strengths to the table. For instance, I once worked with a client in the offshore oil industry who swore by galvanized steel slings. The salt spray was no match for these robust lifters!

Specifications and Safety Standards

When it comes to customizing endless wire rope slings, there's more to consider than just the material. Key specifications include:

- Diameter: Affects the sling's load capacity and flexibility. Remember, bigger isn't always better!

- Length: Tailored to your specific lifting requirements and equipment setup.

- End fittings: Options like thimbles or hooks can be added for easier attachment.

But here's the kicker - all these customizations must adhere to stringent safety standards. OSHA regulations and ASME standards are not just guidelines; they're lifesavers. At iRopes, we take pride in ensuring every sling we produce meets or exceeds these crucial safety benchmarks.

Always ensure your endless wire rope slings have a minimum design factor of 5, as recommended by OSHA. This means the sling's breaking strength should be at least five times its rated load capacity.

Choosing the right specifications isn't just about meeting standards; it's about optimizing your lifting operations. Have you considered how a slight change in your sling's specifications could boost your efficiency?

At iRopes, we don't just manufacture slings; we craft solutions. Our team of experts is always ready to help you navigate the world of customization, ensuring you get an endless wire rope sling that's not just fit for purpose, but perfect for your unique needs. Why settle for off-the-shelf when you can have tailor-made?

Industrial Applications of Endless Wire Rope Slings

Endless wire rope slings are the unsung heroes of heavy-duty industrial lifting. These versatile workhorses are the backbone of countless operations across various sectors. Let's dive into the world of industrial applications and discover how these robust slings are making a difference in the field.

Versatile Uses in Heavy-Duty Lifting Operations

From towering construction sites to bustling shipping yards, endless wire rope slings are the go-to choice for demanding lifting tasks. I've seen these resilient slings in action across numerous industries, and their performance never ceases to amaze me.

- Construction marvels: On high-rise building sites, endless wire rope slings effortlessly hoist massive steel beams and prefabricated sections, ensuring precise placement even in challenging wind conditions.

- Maritime muscle: In shipyards, these slings are the lifeline for moving hefty propellers and engine components, their corrosion-resistant properties standing up to the harsh marine environment.

- Mining might: Deep underground, endless wire rope slings tackle the Herculean task of moving heavy machinery and ore, their durability withstanding the abrasive conditions.

The secret to their success? Even load distribution. Unlike their single-leg counterparts, endless wire rope slings spread the weight across their entire circumference, reducing stress points and enhancing safety. This feature is particularly crucial when handling delicate or irregularly shaped loads.

Have you ever wondered about the various rigging configurations these slings can achieve? From choker hitches that grip loads tightly to basket configurations that cradle wide objects, the versatility is truly impressive. I once witnessed a skilled rigger use a combination of vertical and basket hitches to lift an oddly shaped piece of industrial equipment - it was like watching an intricate dance of steel and precision.

Benefits of Endless Wire Rope Slings in Manufacturing

In the manufacturing sector, endless wire rope slings are revolutionizing material handling and equipment installation processes. Their unique properties offer several advantages that boost both safety and efficiency:

- Unmatched durability: These slings can withstand repeated use in harsh factory environments, outlasting many alternative lifting solutions.

- Flexibility meets strength: The ability to conform to irregular shapes while maintaining incredible load capacity makes them ideal for handling diverse manufacturing components.

- Temperature tolerance: From scorching foundries to freezing cold storage facilities, endless wire rope slings maintain their integrity across a wide temperature range.

I recall a visit to an automotive plant where endless wire rope slings were being used to maneuver engine blocks along the assembly line. The precision and speed at which these slings operated were crucial in maintaining the plant's tight production schedule. It was a testament to how the right lifting solution can significantly impact manufacturing efficiency.

Did you know? Endless wire rope slings can improve workplace safety in manufacturing settings. Their design minimizes the risk of load slippage, reducing the potential for accidents and injuries.

At iRopes, we've had the privilege of serving diverse industrial customers, each with unique lifting challenges. Our experience has taught us that the key to success lies in understanding the specific needs of each application and tailoring our endless wire rope slings accordingly. Whether it's a custom diameter for a particular load capacity or a specialized coating for extreme environments, we're committed to providing solutions that elevate industrial lifting to new heights.

As you consider your next industrial lifting project, ask yourself: Could endless wire rope slings be the game-changer you've been looking for? With their versatility, durability, and safety features, they might just be the perfect fit for your heavy-duty lifting needs. Explore more on Top Cotton and Nylon Cord Manufacturers for Marine Safety and Exploring Single Braided Rope and Single Braid Line Solutions from iRopes!

Choosing the right endless wire rope sling is crucial for ensuring safety and efficiency in lifting operations. iRopes specialises in the customisation of endless wire rope slings, offering a wide range of materials, diameters, and patterns to meet diverse industrial needs. Key factors like wire rope sling diameter significantly impact load capacity, making it vital to select the appropriate size for your application. With their expertise in manufacturing high-quality, tailored lifting solutions, iRopes stands out in the industry, providing durable and flexible endless wire ropes designed to handle the toughest challenges with precision and reliability.

Contact Us for Custom Endless Wire Rope Sling Solutions

The form above is your gateway to exploring customised endless wire rope slings by iRopes. Don't miss the opportunity to enhance your lifting operations with the perfect sling for your needs. Reach out today to discuss your requirements and discover how our tailored solutions can bring unmatched value and performance to your industrial applications.