Have you ever considered how a simple piece of rope could mean the difference between life and death at sea? In the high-stakes world of marine safety, the choice of cordage is far from trivial. As a leading manufacturer of professional marine, safety, and arbour rope and cordage, we understand the critical role these unassuming tools play in keeping seafarers safe and operations running smoothly.

Picture this: a storm-tossed vessel battling fierce waves, its crew relying on the strength and durability of their ropes to secure vital equipment and, potentially, save lives. In such moments, the quality of your cordage isn't just a matter of preference—it's a necessity.

In this blog post, we'll dive into the world of cotton cord manufacturers, nylon cord manufacturers, and braided cord manufacturers, exploring how their products contribute to marine safety. We'll unravel the unique properties of each material, from the natural strength of cotton to the synthetic resilience of nylon, and examine why braided cords have become a go-to choice for many maritime applications.

Whether you're outfitting a small pleasure craft or a large commercial vessel, understanding the nuances of marine cordage is crucial. Join us as we navigate the seas of rope manufacturing, highlighting the top producers in the industry and offering insights that could prove invaluable for your maritime safety needs. After all, when it comes to safety at sea, you're only as strong as the ropes you rely on.

Cotton Cord Manufacturers and Their Role in Marine Safety

When it comes to maritime applications, the choice of rope can make all the difference between smooth sailing and potential disaster. Cotton cord manufacturers play a crucial role in ensuring marine safety, offering a unique blend of qualities that make their products indispensable in various nautical settings.

Benefits of Cotton Ropes in Maritime Applications

You might be wondering, "Why cotton when there are so many synthetic options available?" Well, let me tell you about a time I was out on a fishing trawler off the coast of Queensland. The salty air was thick with moisture, and I noticed the crew handling some particularly sturdy-looking ropes. That's when I learned about the remarkable properties of cotton cords in marine environments.

- Superior moisture absorption: Cotton ropes excel at wicking away water, keeping your hands dry and maintaining a secure grip even in wet conditions.

- Natural insulation: These ropes provide excellent thermal insulation, protecting your hands from temperature extremes common in marine settings.

- Gentle on the skin: Unlike some synthetic materials, cotton is soft and less likely to cause rope burn during handling.

Comparing Cotton Cords to Other Marine Rope Materials

Now, you might be thinking, "But aren't synthetic ropes stronger?" You're not wrong, but strength isn't everything in the world of marine safety. Cotton cords offer a unique set of advantages that complement the strengths of synthetic materials:

- Eco-friendly option: Cotton is biodegradable, reducing environmental impact compared to synthetic alternatives.

- UV resistance: While not as resistant as some synthetics, quality cotton ropes hold up well under sun exposure.

- Knot integrity: Cotton ropes maintain knot strength even when wet, a critical factor in marine applications.

Have you ever considered the importance of rope selection in your maritime adventures? The right choice can significantly enhance your safety and overall experience on the water.

Cotton cord manufacturers continue to innovate, developing treatments and blends that enhance the natural properties of cotton while addressing its limitations. These advancements ensure that cotton ropes remain a viable and valuable option in the marine safety toolkit, working alongside synthetic materials to provide comprehensive solutions for various nautical needs.

Next time you're preparing for a sea voyage or simply enjoying a day on the water, take a moment to appreciate the humble cotton rope. It might just be the unsung hero of your maritime safety equipment.

Nylon Cord Manufacturers: Ensuring Marine Safety

As a seasoned sailor, I've come to appreciate the critical role that nylon cord manufacturers play in ensuring marine safety. During a particularly stormy voyage off the coast of Tasmania, I witnessed firsthand the incredible strength and resilience of nylon ropes. The way they absorbed the shock of crashing waves and held firm against the relentless pull of the sea was nothing short of remarkable.

Properties of Nylon Rope for Maritime Applications

Nylon cords have become the go-to choice for many maritime applications, and for good reason. Let's dive into the properties that make them stand out:

- Exceptional strength-to-weight ratio: Nylon ropes punch above their weight, offering incredible strength without the bulk.

- Impressive shock absorption: The elasticity of nylon allows it to absorb sudden loads, reducing the risk of snapping under pressure.

- Resistance to marine organisms: Unlike natural fibres, nylon stands strong against rot, mildew, and pesky marine creatures.

- UV and chemical resistance: Nylon cords maintain their integrity even when exposed to harsh sunlight and chemical agents commonly found in marine environments.

Safety Factors and Standards in Marine Rope Production

When it comes to marine safety, there's no room for compromise. Nylon cord manufacturers understand this and adhere to strict safety standards:

- Safety factor consideration: For non-critical uses, a safety factor of 5-12 is typically employed, while lifelines demand a higher factor of 15.

- Industry certifications: Reputable manufacturers ensure their products meet or exceed standards set by organisations like the International Maritime Organization (IMO).

- Rigorous testing: From tensile strength to abrasion resistance, nylon ropes undergo extensive testing to ensure they're up to the task.

Have you ever wondered about the science behind rope selection for different marine applications? The choice between a braided or twisted construction, or selecting the appropriate diameter, can significantly impact performance and safety.

Nylon cord manufacturers continue to innovate, developing advanced blends and treatments to enhance the natural properties of nylon. These advancements ensure that nylon ropes remain at the forefront of marine safety, providing reliable solutions for mooring, anchoring, towing, and salvage operations. Learn more about the strength of black double-braided nylon rope for marine use, which is one of the top choices for tough maritime conditions.

Next time you're out on the water, take a moment to appreciate the nylon ropes around you. They're not just pieces of equipment; they're the result of meticulous engineering and a commitment to safety from dedicated nylon cord manufacturers. After all, when you're facing the unpredictable nature of the sea, wouldn't you want the most reliable rope by your side?

Braided Cord Manufacturers in Marine Safety Applications

When it comes to marine safety, braided cord manufacturers play a crucial role in providing robust and reliable solutions. As someone who's spent countless hours on the water, I've come to appreciate the importance of high-quality braided cords in various maritime applications. Let me share with you why these cords are indispensable for ensuring safety at sea.

Advantages of Braided Cords for Maritime Safety

Braided cords offer a unique set of benefits that make them ideal for marine environments. During a recent sailing expedition along the Great Barrier Reef, I witnessed firsthand how these cords outperformed traditional twisted ropes in challenging conditions.

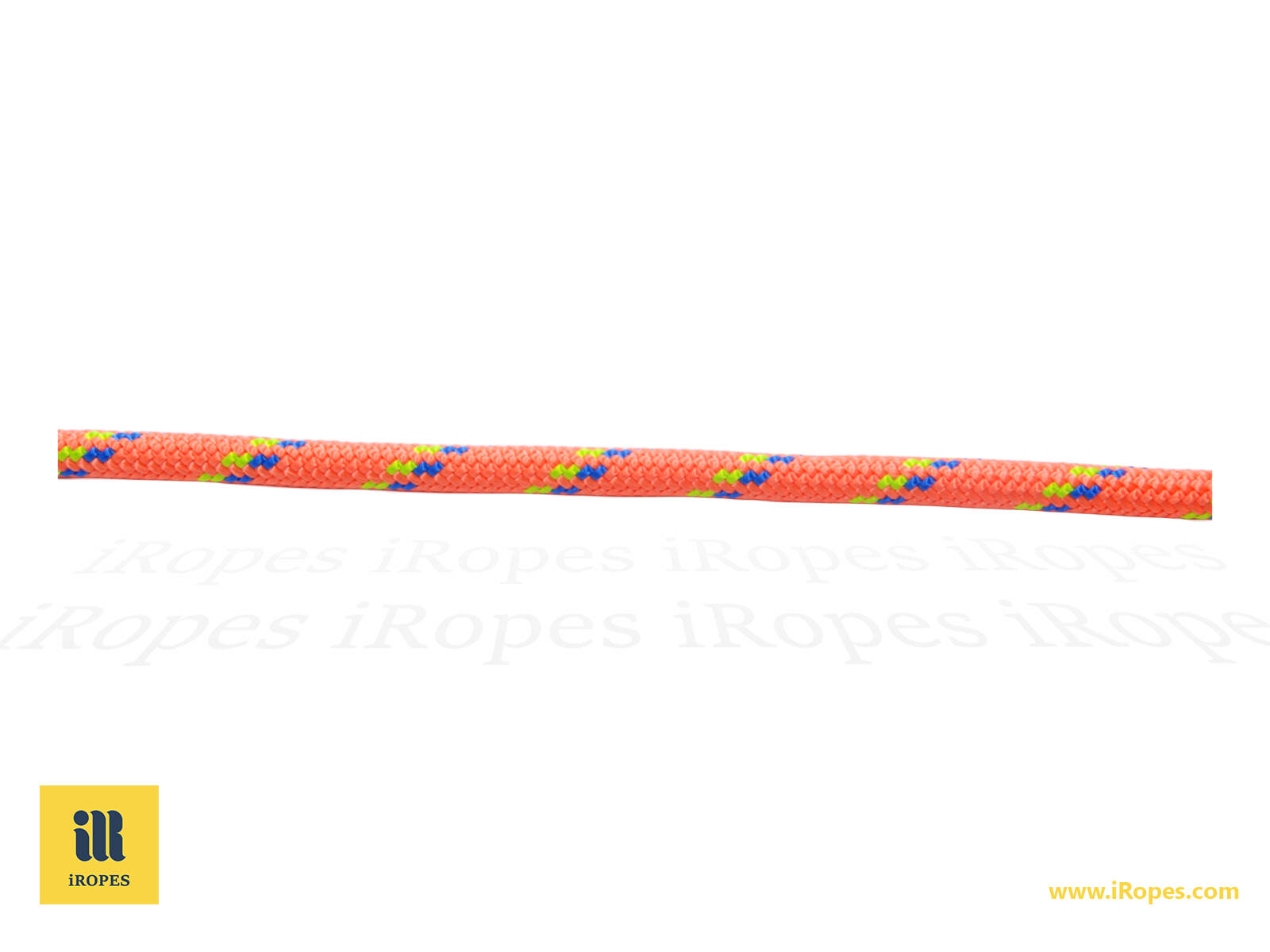

- Superior strength and durability: Braided cords boast a higher strength-to-weight ratio compared to their twisted counterparts, ensuring they can withstand the harsh marine environment.

- Excellent handling characteristics: The smooth surface of braided cords reduces the risk of snagging and makes them easier to handle, even in wet conditions.

- Resistance to kinking and tangling: This property is crucial for quick deployment in emergency situations, potentially saving lives when every second counts.

Types of Braided Cords Used in Marine Environments

Braided cord manufacturers offer a variety of materials to suit different marine safety applications. Let's explore the most common types:

- Nylon braided cords: Excellent for docking and mooring lines due to their high strength and elasticity, which helps absorb shock loads.

- Polyester braided cords: Known for their low stretch properties, making them ideal for applications where maintaining a fixed length is crucial.

- Polypropylene braided cords: These float on water, making them perfect for safety lines and rescue operations.

Have you ever wondered which type of braided cord would best suit your specific marine safety needs? The choice largely depends on the intended use and the unique challenges of your maritime environment.

Braided cord manufacturers continue to innovate, developing advanced synthetic fibres and manufacturing techniques to enhance the performance of their products. These advancements ensure that braided cords remain at the forefront of marine safety, providing reliable solutions for a wide range of applications, from small pleasure crafts to large commercial vessels. Explore the mastery of double-braid polyester ropes in yachting for more insights on the advantages of braided cords in marine settings.

Remember, when it comes to marine safety, choosing the right braided cord can make all the difference. So next time you're outfitting your vessel or updating your safety equipment, take a moment to consider the vital role these unassuming yet crucial components play in keeping you safe on the water.

Selecting the Right Marine Rope Manufacturer for Safety Needs

When it comes to marine safety, choosing the right rope manufacturer is as crucial as selecting the rope itself. As someone who's spent years navigating treacherous waters, I can't stress enough how vital this decision can be. Let's dive into the key factors you should consider when selecting a marine rope supplier for your safety needs.

Key Factors to Consider When Choosing a Marine Rope Supplier

Selecting a marine rope manufacturer isn't just about finding the cheapest option. It's about ensuring the safety and reliability of your maritime operations. Here are some critical factors to keep in mind:

- Expertise in marine-grade cords: Look for manufacturers with a proven track record in producing ropes specifically designed for marine environments.

- Quality of materials: The best manufacturers use high-grade materials that can withstand the harsh conditions at sea.

- Manufacturing processes: Advanced production techniques can significantly enhance the performance and longevity of marine ropes.

- Certifications: Ensure the manufacturer complies with industry standards such as those set by the International Maritime Organization (IMO).

Types of Marine Ropes and Their Specific Applications

Different marine applications require specific types of ropes. Understanding these can help you choose the right manufacturer for your needs:

- Nylon ropes: Ideal for docking and mooring due to their strength and elasticity. They absorb shock loads effectively, reducing stress on your vessel.

- Polyester ropes: Perfect for applications requiring minimal stretch, such as halyards and sheet lines on sailboats.

- Polypropylene ropes: These float on water, making them excellent for water rescue operations and as tow lines.

Have you ever considered how the right rope could make a difference in your maritime operations? The choice between a nylon and polyester rope, for instance, could significantly impact your vessel's performance and safety. Discover the ultimate high tensile strength ropes that elevate your maritime safety and performance.

When selecting a marine rope manufacturer, it's crucial to consider their ability to provide custom solutions. Every maritime operation is unique, and the best manufacturers understand this. They should offer custom design and manufacturing services tailored to your specific needs, whether you're outfitting a small pleasure craft or a large commercial vessel.

Lastly, don't underestimate the importance of customer support and technical assistance. A reputable manufacturer should be more than just a supplier; they should be a partner in ensuring your maritime safety. Look for manufacturers who offer comprehensive support, from helping you choose the right rope for your application to providing guidance on proper use and maintenance.

Remember, when it comes to marine safety, cutting corners on rope quality is never worth the risk. Invest in high-quality, marine-grade ropes from reputable manufacturers. Your safety at sea depends on it.

Ensuring marine safety involves selecting durable and reliable cotton, nylon, and braided cords. Cotton cord manufacturers offer eco-friendly, moisture-resistant ropes perfect for maritime environments, while nylon cord manufacturers provide high-tensile strength and UV-resistant ropes, ideal for harsh marine conditions. Additionally, braided cord manufacturers deliver customised, kink-resistant solutions that enhance operational efficiency and safety. Choosing the right manufacturer, with expertise in marine-grade materials and robust manufacturing processes, is crucial to securing quality cordage for marine, safety, and arbour applications. Invest in superior-grade rope to uphold safety and performance standards.

Explore Superior Marine Cordage Options

To ensure the highest standards of marine safety and performance, please fill in the inquiry form above to learn more about our professional marine, safety, and arbour rope and cordage solutions. Our team is ready to assist you with all your cordage needs.