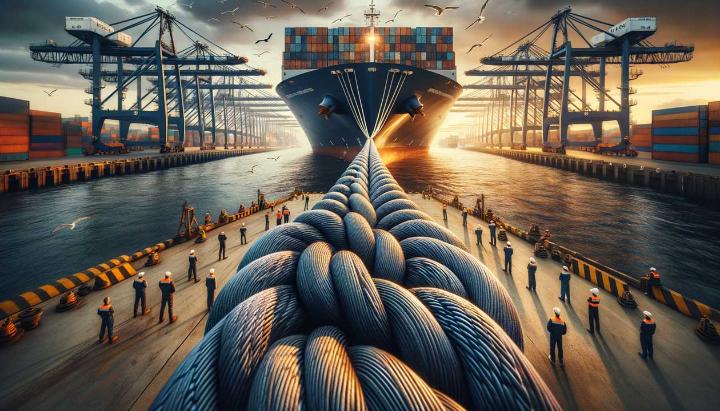

Imagine a scenario where your vessel is securely moored, withstanding the relentless force of crashing waves and howling winds. The difference between a peaceful night at anchor and a catastrophic event often lies in the strength and reliability of your mooring lines. In the world of marine safety, the choice of nylon mooring line can make or break your nautical adventures, especially in coastal and port areas.

As a leading rope manufacturer catering to wholesale customers globally, iRopes understands the critical importance of selecting the right nylon mooring line for your specific needs. From recreational boats to commercial vessels, we bring our expertise in customized rope solutions to help you navigate the challenges of the marine environment with confidence.

In this ultimate guide, we'll delve into the intricacies of nylon mooring lines, exploring their unique advantages, key factors to consider, and best practices for maximizing their performance and longevity. Whether you're a seasoned mariner or a newcomer to the world of boating, this comprehensive resource will equip you with the knowledge to make informed decisions that ensure the safety and security of your vessel, no matter the conditions.

Understanding the Basics of Nylon Mooring Lines

As you navigate the waters, whether for commercial purposes or leisure sailing, ensuring your vessel is securely moored is paramount. Nylon mooring lines have become a trusted choice for mariners worldwide, and for good reason. These versatile ropes offer a perfect blend of strength, elasticity, and durability, making them a reliable partner on your nautical adventures.

What are Nylon Mooring Lines?

Nylon mooring lines are synthetic fiber ropes designed specifically for securing vessels to docks, buoys, or other mooring points. They are constructed from nylon, a tough and resilient material that can withstand the rigors of the marine environment. The widespread popularity of nylon mooring lines stems from their unique combination of properties that make them ideal for this critical task.

Benefits of Using Nylon for Mooring Lines

- Exceptional strength – Nylon fibers are incredibly strong, offering superior tensile strength to ensure your vessel remains safely anchored, even in challenging conditions.

- Elasticity and stretch – Unlike rigid materials, nylon mooring lines possess a degree of elasticity, allowing them to absorb shock loads and minimize the risk of snapping under sudden strain.

- Abrasion resistance – The smooth surface and durable construction of nylon ropes make them resistant to chafing and abrasion, prolonging their lifespan even in high-friction scenarios.

While other materials like polyester and polypropylene are also used for mooring lines, nylon stands out for its superior combination of strength, stretch, and durability. Whether you're securing a small recreational boat or a massive commercial vessel, nylon mooring lines provide the reliable performance you need to keep your craft safely in place.

Key Factors to Consider When Choosing a Nylon Mooring Line Rope

When it comes to securing your vessel, the choice of mooring line is crucial. Nylon ropes have become a go-to option for many mariners due to their exceptional combination of strength, elasticity, and resistance to the harsh marine environment. However, not all nylon mooring lines are created equal, and selecting the right one can make a significant difference in ensuring the safety and longevity of your craft.

Strength and Durability

The most fundamental consideration when choosing a nylon mooring line is its strength and durability. A robust line with a high breaking strength is essential for securely anchoring your vessel, even in challenging conditions. The construction and diameter of the rope play a vital role in determining its overall strength and durability. Thicker ropes with a higher strand count generally offer greater strength, but it's essential to strike the right balance between strength and maneuverability.

Stretch and Elasticity

One of the key advantages of nylon mooring lines is their inherent elasticity and stretch capacity. This unique property allows the lines to absorb shock loads and dynamic forces, reducing the risk of snapping or causing damage to your vessel or the mooring point. Imagine a scenario where your boat is being tossed by strong winds or currents – a nylon line with the right amount of stretch can act as a shock absorber, preventing sudden jolts and potential breakages.

Abrasion and UV Resistance

The marine environment can be harsh, with exposure to abrasion from chafing against rough surfaces and intense UV radiation from the sun. Nylon mooring lines offer excellent resistance to both abrasion and UV degradation, ensuring they maintain their integrity and strength over extended periods of use. However, proper handling and maintenance are still essential to maximize the lifespan of your nylon lines.

When selecting a nylon mooring line rope, consider factors like the anticipated levels of abrasion and UV exposure. Lines with specialized coatings or tighter constructions may provide enhanced protection in particularly demanding environments.

By carefully evaluating these key factors – strength, elasticity, and resistance to environmental stressors – you can choose a nylon mooring line that not only meets your vessel's specific requirements but also provides the peace of mind that comes with knowing your craft is securely anchored, no matter the conditions.

Selecting the Right Nylon Mooring Line for Your Boat

As a boat owner, one of the most crucial decisions you'll make is choosing the right mooring line to secure your vessel. After all, your boat is a significant investment, and you want to ensure its safety and longevity, whether you're docking at a marina or anchoring offshore. Nylon mooring lines are the go-to choice for many mariners, and for good reason.

Factors to Consider When Choosing a Nylon Mooring Line

- Boat size and length – The diameter of your mooring line should be proportional to the size of your boat. As a general rule, for boats up to 25 feet, a 3/8-inch line is suitable. For vessels between 25 and 35 feet, choose a 1/2-inch line. Boats ranging from 35 to 45 feet require a 5/8-inch line, while larger yachts and commercial vessels may need a 3/4-inch line or even thicker.

- Intended use – Coastal cruising and docking at marinas may require different mooring line specifications than offshore sailing or anchoring in remote areas. Consider the typical conditions you'll encounter, such as wind, waves, and currents, when selecting the appropriate line.

- Weather conditions – If you plan to moor your boat in areas prone to harsh weather, such as strong winds or storms, it's essential to choose a more durable and thicker nylon mooring line. The added strength will help ensure your vessel remains securely anchored, even in challenging conditions.

- Docking environment – The type of docking environment can significantly impact the mooring line requirements. For example, if you're mooring in an area with strong tidal currents or heavy boat traffic, you may need a longer and more robust line to compensate for the additional forces and potential chafe.

Maximizing the Lifespan and Performance of Nylon Mooring Lines

Once you've selected the perfect nylon mooring line for your boat, it's crucial to maintain it properly to ensure its longevity and performance. Here are some tips to help you get the most out of your investment:

- Proper care and maintenance – Inspect your mooring lines regularly for signs of wear, such as chafe, fraying, or discoloration. Storing them in a cool, dry place away from direct sunlight can help prevent premature degradation. Additionally, cleaning your lines with a mild soap and fresh water can remove salt buildup and other contaminants.

- Splicing and attaching hardware – Consider splicing the ends of your mooring lines or adding hardware like thimbles or eye splices. These techniques can enhance the line's durability and provide secure attachment points for cleats or other mooring hardware.

- Replacement considerations – Even with proper care, mooring lines will eventually wear out and need to be replaced. Be vigilant for signs of excessive wear, such as significant loss of diameter or compromised integrity. It's better to err on the side of caution and replace a worn line than risk a potential failure.

- Environmental impact – When disposing of old or damaged mooring lines, explore eco-friendly options like recycling programs or proper disposal facilities. Nylon ropes can take years to decompose, so it's essential to minimize their environmental impact.

Remember, investing in high-quality nylon mooring lines and following best practices for their care and maintenance can ensure your boat stays securely moored, no matter the conditions. Don't hesitate to consult with experienced boaters or marine professionals for additional guidance on selecting and maintaining the perfect mooring line for your vessel.

Best Practices for Using and Maintaining Nylon Mooring Lines

As a boat owner or marina operator, ensuring the safety and longevity of your nylon mooring lines is crucial. These versatile ropes are designed to withstand the harsh marine environment, but they still require proper care and maintenance to perform at their best. By following some best practices, you can maximize the lifespan of your nylon lines and keep your vessel securely anchored, no matter the conditions.

Selection and Inspection of Nylon Mooring Lines

The first step is to choose the right nylon mooring line for your specific needs. Consider factors like your vessel's size, the anticipated docking conditions, and the potential for exposure to abrasion or UV radiation. Once you've selected the appropriate line, regular inspections are key to identifying any signs of wear or damage.

- Visual inspection – Before each use, carefully examine your nylon lines for any visible fraying, discoloration, or cuts that could compromise their strength.

- Tactile inspection – Run your hands along the length of the line, feeling for any stiff or brittle sections that may indicate internal damage or excessive wear.

- Knot and splice inspection – Pay close attention to areas where knots or splices have been tied, as these can be potential weak points in the line.

If you notice any significant signs of wear or damage, it's better to be safe and replace the line altogether. A compromised mooring line puts your vessel and those around you at risk.

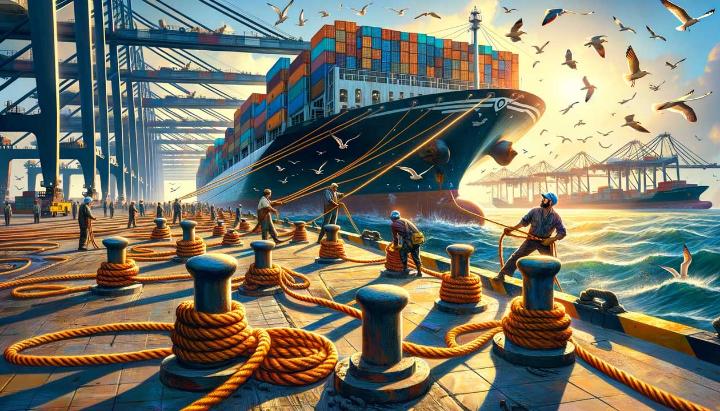

Proper Usage and Handling of Nylon Lines

Proper handling and usage techniques can go a long way in preserving the integrity of your nylon mooring lines. Here are some best practices to keep in mind:

- Knot tying – When tying knots, use proven knot styles like the bowline or clove hitch that distribute the load evenly along the line. Avoid knots that create sharp bends or pinch points, as these can weaken the nylon fibers over time.

- Chafe protection – Use chafe guards or protective sleeves on areas where the line may rub against rough surfaces, such as dock pilings or cleats. This simple step can significantly reduce the risk of abrasion damage.

- Proper coiling – When not in use, coil your nylon lines in a way that minimizes kinks, twists, or excessive bending. Improper coiling can lead to permanent deformations that compromise the line's strength and flexibility.

By handling your nylon mooring lines with care and following proper techniques, you'll not only extend their lifespan but also ensure they perform optimally when you need them most.

Cleaning and Maintenance Routines

Even with the best handling practices, your nylon mooring lines will inevitably accumulate dirt, salt, and other contaminants over time. Regular cleaning and maintenance are essential to keep them in top condition. Here's what you should do:

- Freshwater rinse – After each use, rinse your nylon lines with fresh water to remove any salt or debris. This simple step can prevent long-term damage and degradation.

- Mild soap and scrubbing – For tougher stains or buildup, use a mild soap and a soft-bristled brush to gently scrub the line. Avoid harsh chemicals or abrasive cleaners that could damage the nylon fibers.

- Drying and storage – After cleaning, ensure your lines are thoroughly dry before storing them in a cool, dry place away from direct sunlight. Moisture can lead to mildew and premature deterioration.

- Lubrication – Consider applying a specialized nylon rope lubricant or conditioner every few months. This can help maintain the line's flexibility and prevent stiffening or cracking over time.

By incorporating these cleaning and maintenance routines into your regular boating routine, you'll not only prolong the life of your nylon mooring lines but also ensure they remain in optimal condition for when you need them most.

To explore more about how versatile nylon and Dyneema cordage can benefit your boating experience, click here. If you're interested in the variations of ropes for different purposes, our guide on comparing strong ropes and strong wire rope provides valuable insights. Check it out here.

Remember, investing time and effort into caring for your nylon mooring lines is an investment in the safety and longevity of your vessel. Follow these best practices, and you'll be able to rely on your lines for many adventures to come. For more information on customized marine ropes, read our ultimate guide here.

Get Expert Advice on Selecting the Perfect Nylon Mooring Line

Choosing the right mooring line rope is crucial for securely anchoring your vessel in coastal and port areas. This ultimate guide covers essential factors like breaking strength, rope diameter, elongation, UV resistance, and proper maintenance. Nylon mooring lines are praised for their strength, elasticity, and durability. Make an informed choice by considering your vessel size, weather conditions, and docking environment, and always work with reputable suppliers. For any further guidance, fill in the form above to get expert advice tailored to your needs.