Have you ever wondered why choosing the right rope can mean the difference between success and failure in critical applications? In the world of high-performance ropes, two materials stand out: polyester combo rope and nylon rope. As a leading manufacturer with decades of experience in rope technology, we've seen firsthand how these materials shape the industry's landscape.

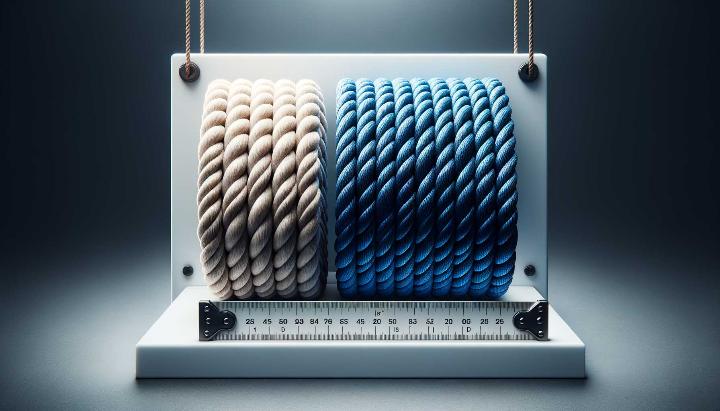

When it comes to the difference between nylon and polyester rope, the devil is in the details. While both materials offer impressive strength and durability, their unique characteristics make them suited for distinctly different applications. The innovative design of polyester combo rope, with its sophisticated blend of materials, has revolutionised how we approach challenging rope applications across industries.

In this comprehensive guide, we'll explore the distinct advantages and limitations of each material, helping you make an informed decision for your specific needs. Whether you're involved in marine operations, industrial applications, or outdoor activities, understanding these differences could be the key to optimising your rope selection and enhancing operational safety and efficiency.

Understanding Polyester Combo Rope Construction and Uses

When it comes to reliable rope solutions, polyester combo rope stands out as a remarkable innovation in rope technology. Having worked extensively with various rope types in marine applications, I've come to appreciate the ingenious design that makes these ropes so versatile.

What Makes Polyester Combo Rope Unique

At its core, polyester combo rope features a sophisticated design that combines the best of two materials. The outer strands are crafted from high-tensile polyester fibers, while the inner core consists of polypropylene yarns. This thoughtful combination creates a rope that delivers exceptional performance across multiple applications.

- Three-strand construction provides optimal balance between strength and handling

- Polyester outer layer ensures superior UV resistance and durability

- Polypropylene core contributes to the rope's excellent strength-to-weight ratio

Key Properties and Applications

What truly sets polyester combo rope apart is its impressive range of physical properties. The minimal stretch characteristics make it ideal for static load applications, while its resistance to UV degradation ensures longevity in outdoor settings. Have you ever noticed how some ropes become brittle after extended sun exposure? That's not the case with polyester combo rope.

- Outstanding chemical resistance

- Excellent abrasion resistance

- High tensile strength

From marine applications to general utility work, polyester combo rope proves its worth in demanding environments. Its balanced properties make it particularly suitable for applications where reliability and durability are non-negotiable requirements.

Exploring the Properties of Nylon Rope

After exploring polyester combo rope, let's turn our attention to nylon rope - a material that has revolutionized the rope industry with its remarkable characteristics. Having tested numerous nylon ropes in challenging conditions, I can attest to their exceptional performance capabilities.

Essential Physical Properties of Nylon Rope

Nylon rope is crafted from synthetic polymer fibers that offer an impressive combination of strength and flexibility. What makes nylon truly special is its molecular structure, which allows for exceptional load-bearing capacity while maintaining remarkable elasticity. Have you ever wondered why climbing ropes feel so different from standard utility ropes? The secret lies in nylon's unique properties.

- Superior Tensile Strength - Pound for pound, nylon rope can match or exceed the strength of steel wire rope

- Exceptional Elasticity - Capable of stretching 15-28% under load, providing excellent shock absorption

- Remarkable Recovery - Returns to its original length after stretching, maintaining structural integrity

- Weather Resistance - Performs reliably in various environmental conditions, though requires proper care when wet

Performance Benefits and Applications

The versatility of nylon rope makes it particularly valuable across numerous applications. Its high stretch properties make it perfect for dynamic loading situations, while its natural softness ensures comfortable handling. When working with heavy loads, I've always appreciated how nylon rope's elastic properties help absorb sudden shocks that could otherwise cause dangerous situations.

- Ideal for climbing and safety applications

- Excellent for marine use and mooring

- Perfect for towing and recovery operations

Limitations and Considerations

While nylon rope excels in many areas, it's important to understand its limitations. The material can absorb water, which temporarily reduces its strength by 10-15%. However, this characteristic rarely poses significant problems when the rope is properly maintained and used within its specified parameters.

For a detailed guide on customizing nylon rope and the endless possibilities it offers, you might want to explore nylon rope roll customization for your needs.

Understanding Nylon vs Polyester Rope Differences

Having explored both rope types individually, let's dive into a detailed comparison of their key differences. Through years of testing various ropes in challenging environments, I've observed how each material's unique properties can significantly impact performance in different applications.

Strength and Durability Profile

When it comes to raw strength, both materials are impressive performers, but their characteristics differ notably. Have you ever noticed how some ropes feel more rigid while others have a more supple touch? This tactile difference actually reflects their underlying strength properties.

- Breaking Strength - Polyester typically offers slightly higher breaking strength when dry, while nylon maintains better strength retention under dynamic loads

- Long-term Durability - Polyester excels in maintaining consistent performance over time, especially in outdoor conditions

- Impact Resistance - Nylon's superior shock absorption makes it ideal for applications involving sudden load changes

Stretch and Elasticity Characteristics

In my experience working with both materials, the difference in stretch characteristics is perhaps the most crucial factor in choosing between them. Polyester's minimal stretch (around 2.6%) contrasts sharply with nylon's significant elasticity (up to 15-28%), making each ideal for different scenarios. For an in-depth comparison of braided ropes, including nylon and polyester, you can read more about nylon and polyester braided rope.

Environmental Performance

Weather resistance and chemical compatibility can make or break a rope's effectiveness in specific applications. During my time in marine environments, I've witnessed firsthand how these materials react differently to various conditions.

- Water Resistance - Polyester maintains consistent strength when wet, while nylon can lose up to 15% strength in wet conditions

- UV Stability - Polyester shows superior resistance to UV degradation compared to nylon

- Chemical Tolerance - Both materials offer good chemical resistance, though polyester generally performs better with acids

Cost-Value Analysis

While polyester rope typically commands a slightly higher price point, its longer service life in outdoor applications often provides better value over time. However, nylon's unique properties make it irreplaceable in specific applications where shock absorption is crucial. The key is matching the material to your specific needs rather than focusing solely on initial cost.

Understanding the intricate features of these materials can help you make better choices. For additional insights, check out our guide on diamond braid polyester rope structure.

```htmlWhen selecting rope materials, understanding the difference between nylon and polyester rope is crucial for optimal performance. The polyester combo rope is an innovative option, combining high-tensile polyester fibers with a polypropylene core. This combo rope delivers exceptional UV resistance, minimal stretch, and superior durability, making it ideal for marine and static load applications. In contrast, nylon rope is renowned for its strength, elasticity, and shock absorption, making it perfect for dynamic loading and safety applications. By comparing their properties—strength, elasticity, and environmental resistance—buyers can choose the right material for their needs, considering both initial cost and long-term value.

Get Customised Rope Solutions for Your Needs

Fill out the form above to connect with iRopes, your trusted partner for high-quality, customized rope solutions. Whether you need a polyester combo rope or a nylon rope tailored for specific applications, our experts are ready to assist and ensure you receive the perfect product for your industry needs.

```