Have you ever marvelled at the intricate dance of fibres that make up a high-quality rope? The diamond braid polyester rope, a marvel of modern engineering, is revolutionising industries across the globe. As a leading rope manufacturer, iRopes has mastered the art of crafting these versatile cords, weaving strength and durability into every strand.

In this post, we'll unravel the mysteries of diamond braid polyester rope structure, exploring why it's become the go-to choice for everything from marine applications to industrial rigging. We'll delve into the unique properties of diamond braid cord and discover why polyester rope philippines is gaining popularity in tropical climates.

Whether you're a seasoned professional or a curious newcomer, understanding the intricacies of rope structure is crucial for making informed decisions. Join us as we examine the key factors that set diamond braid polyester rope apart and learn how to select the perfect rope for your specific needs. Get ready to elevate your rope game and discover why this remarkable cordage is more than just a tool—it's a game-changer.

Understanding Diamond Braid Polyester Rope

Have you ever marveled at the intricate design of a well-crafted rope? As someone who's spent years working with various types of cordage, I can tell you that diamond braid polyester rope is truly a marvel of engineering. Let's dive into the fascinating world of this versatile and robust rope type.

Construction and Properties of Diamond Braid Rope

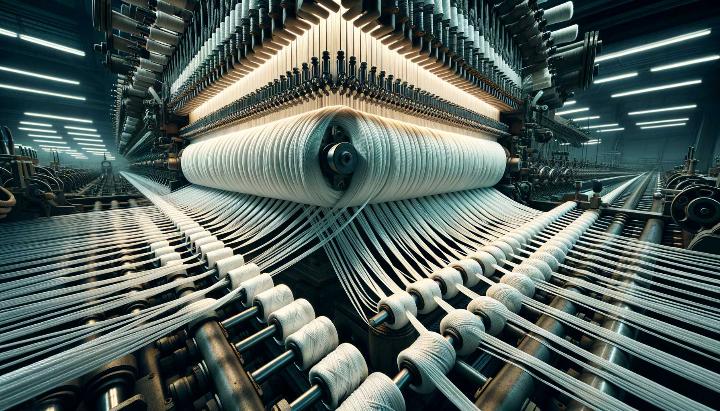

Diamond braid polyester rope gets its name from its unique construction process. Imagine a series of polyester fibers dancing around each other in an intricate over-under pattern, creating a visually striking diamond-shaped pattern on the rope's surface. This isn't just for show - the braiding technique significantly enhances the rope's strength and durability.

The polyester fibers used in these ropes are synthetic marvels. They offer an impressive combination of high strength and low stretch, making them ideal for a wide range of applications. I've personally used diamond braid polyester ropes in various situations, and their performance never ceases to amaze me.

Advantages and Applications of Polyester Diamond Braid

What sets diamond braid polyester rope apart from other types? Let me share some key benefits I've observed over the years:

- Exceptional strength-to-weight ratio: These ropes pack a lot of strength into a relatively lightweight package.

- Impressive abrasion resistance: They can withstand rough surfaces and heavy use without fraying or weakening.

- UV and moisture resistance: Perfect for outdoor applications, these ropes maintain their integrity even when exposed to sunlight and water.

- Low stretch properties: This makes them ideal for applications where minimal elongation is crucial.

From marine environments to industrial settings, diamond braid polyester ropes find their place in numerous applications. I've seen them used effectively in boating, as utility lines, and even in some creative DIY projects. Their versatility is truly impressive.

When choosing a diamond braid polyester rope, consider factors like the required diameter, length, and load capacity for your specific needs. To explore more about selecting the right features, read our guide on low stretch polyester ropes. And remember, proper care and maintenance can significantly extend the life of your rope.

Have you used diamond braid polyester rope before? What was your experience like? Understanding the basics of this remarkable rope type can help you make informed decisions for your next project, whether it's for work or play.

Understanding Diamond Braid Cord Structure

As a rope enthusiast who's spent countless hours working with various cordage types, I can confidently say that the diamond braid structure is a true marvel of engineering. Let's dive into the intricate world of diamond braid cord and unravel its secrets together.

Composition and Materials of Diamond Braid Cord

When I first encountered diamond braid cord, I was struck by its versatility. These cords are typically crafted from one of three primary materials:

- Polypropylene: Lightweight and buoyant, perfect for marine applications.

- Nylon: Known for its exceptional strength and elasticity.

- Polyester: Offers a balance of strength and UV resistance.

Each material brings its unique properties to the table, influencing the cord's performance in different environments. For instance, I once used a polyester diamond braid cord for an outdoor project exposed to harsh sunlight, and its UV resistance proved invaluable.

Braiding Techniques for Diamond Braid Patterns

The magic of diamond braid cord lies in its construction. Imagine a intricate dance of fibers, weaving over and under each other in a mesmerizing pattern. Here's how it works:

- Strands are arranged in two sets, each moving in opposite directions.

- As they intertwine, they create a distinctive diamond pattern on the surface.

- This process typically involves either 8 or 16 strands, depending on the desired strength and flexibility.

The braiding angle, or the angle at which the strands intersect, plays a crucial role in determining the cord's characteristics. A tighter angle results in a firmer cord, while a looser angle offers more flexibility. For a deeper understanding of braid rope construction, you might find our comprehensive guide on various types of braids helpful.

How Braiding Structure Contributes to Strength and Durability

The genius of the diamond braid structure lies in its ability to distribute load evenly across all strands. This unique feature contributes significantly to the cord's overall strength and durability. Here's how:

- Even load distribution: When tension is applied, each strand bears an equal share of the load.

- Abrasion resistance: The interlocking pattern helps protect inner fibers from wear and tear.

- Flexibility: The structure allows for some give without compromising strength.

I've personally put diamond braid cords to the test in various scenarios, from sailing to rock climbing, and their performance never fails to impress. The way the structure handles stress and strain is truly remarkable.

Have you ever used a diamond braid cord? What was your experience like? Understanding the intricacies of this rope structure can help you make informed decisions for your next project, whether it's for work or play.

Advantages of Using Polyester Rope in the Philippines

When it comes to choosing the right rope for various applications in the Philippines, polyester rope stands out as a top contender. As someone who's worked extensively with different rope materials across the archipelago, I can attest to the unique advantages polyester offers in our tropical climate.

Strength and Durability of Polyester Rope

One of the most impressive qualities of polyester rope is its remarkable strength-to-weight ratio. I've seen firsthand how this translates to real-world applications:

- High breaking strength: Polyester ropes can handle substantial loads without failing, making them ideal for heavy-duty tasks in construction and marine industries.

- Low stretch properties: Unlike nylon, polyester ropes maintain their length under load, ensuring stability in critical applications like mooring lines for ships in busy Philippine ports.

- Superior durability: Compared to natural fibre ropes, polyester withstands repeated use and harsh conditions without significant wear.

For instance, I once visited a busy fishing port in Zambales where polyester ropes were used extensively. The fishermen praised their reliability, especially when hauling in heavy nets laden with the day's catch.

Weather Resistance and UV Protection

The Philippines' tropical climate can be unforgiving on outdoor equipment, but polyester rope rises to the challenge:

- Excellent UV resistance: Our intense tropical sun can degrade many materials, but polyester rope maintains its integrity even after prolonged exposure. To see how different ropes perform under various conditions, check out our insights on 600 ft anchor lines.

- Moisture resistance: In our humid environment, polyester rope resists water absorption, preventing rot and mildew growth.

- Chemical resistance: This property is particularly valuable in industrial settings where ropes may come into contact with various substances.

I recall a conversation with a resort owner in Palawan who switched to polyester ropes for their beachfront equipment. He was thrilled with how well they held up against the constant assault of sun, salt, and sand.

When compared to other common rope materials used in the Philippines, polyester truly shines:

- vs. Nylon: While nylon is strong, it stretches more and degrades faster under UV exposure.

- vs. Polypropylene: Polyester offers better UV resistance and doesn't float, making it more versatile.

- vs. Natural fibres: Polyester far outperforms in terms of weather resistance and longevity.

Have you used polyester rope in your projects here in the Philippines? I'd love to hear about your experiences. The unique combination of strength, durability, and weather resistance makes polyester rope an excellent choice for a wide range of applications in our beautiful but challenging environment.

Key Factors in Selecting Diamond Braid Polyester Rope

Choosing the right rope for your project can be a bit like finding the perfect dance partner - it needs to have the right moves for the job at hand. As someone who's spent years working with various types of cordage, I can tell you that diamond braid polyester rope is a versatile performer. But how do you know if it's the right fit for your needs? Let's dive into the key factors you should consider when selecting this type of rope.

Strength and Durability Considerations

When it comes to rope selection, strength is often the first thing that comes to mind. Diamond braid polyester rope doesn't disappoint in this department. Its unique construction gives it an impressive strength-to-weight ratio that often surprises first-time users.

- Breaking strength: Always check the rope's breaking strength and ensure it exceeds your intended load by a significant margin.

- Safety factor: OSHA recommends a safety factor between 6 and 9 for synthetic ropes like polyester. This means your working load should be no more than 1/6th to 1/9th of the rope's breaking strength.

- Abrasion resistance: The diamond braid pattern enhances the rope's ability to withstand wear and tear, crucial for applications involving rough surfaces or frequent use.

I once used a diamond braid polyester rope for a heavy-duty outdoor project, and its durability was truly impressive. Even after months of exposure to the elements and constant use, it showed minimal signs of wear.

Application-Specific Properties

Different jobs demand different rope characteristics. Here's where diamond braid polyester rope really shines:

- Low stretch: Unlike nylon, polyester has minimal elongation under load. This makes it ideal for applications where maintaining a specific length is crucial.

- UV resistance: If your rope will be exposed to sunlight, polyester's excellent UV resistance is a significant advantage.

- Water performance: Unlike some materials, polyester doesn't absorb water, maintaining its strength even in wet conditions.

I've seen diamond braid polyester rope excel in various settings, from marine environments to outdoor adventure gear. Its versatility is truly impressive.

When selecting your rope, consider the specific demands of your project. Are you working in a wet environment? Will the rope be exposed to sunlight? Does your application require minimal stretch? These factors will help guide your choice.

Remember, while diamond braid polyester rope is a fantastic all-rounder, it's not always the best choice for every situation. For instance, if you need extreme strength with minimal weight, you might want to consider HMPE (High Modulus Polyethylene) ropes.

Have you used diamond braid polyester rope in your projects? What factors influenced your choice? Understanding these key considerations will help you make an informed decision, ensuring you get the right rope for the job every time.

```htmlThe intricacies of diamond braid polyester rope are a testament to engineering excellence, offering remarkable strength, durability, and low stretch. This rope type boasts a distinct diamond-shaped pattern that not only enhances its aesthetic appeal but also reinforces performance under load. Serving a myriad of applications—from marine to industrial uses—it is a preferred choice for those seeking reliability. In the Philippines, polyester rope's advantages, such as exceptional UV and abrasion resistance, make it indispensable in the tropical climate. Understanding the structure of diamond braid cord aids in selecting the perfect rope for your needs while considering factors like material strength, rope diameter, and environmental exposure. Whether you are a DIY enthusiast or a professional seeking optimal cordage solutions, exploring the world of diamond braid polyester rope can be both enlightening and rewarding.

Explore Your Rope Options Further

Above, you'll find our inquiry form, designed to assist you in discovering the ideal rope solutions for your specific requirements. Don't hesitate to fill in the form for tailored advice and insights into the various possibilities with diamond braid polyester rope. Our team is here to help you unleash the potential of these robust and versatile ropes in your projects.

```