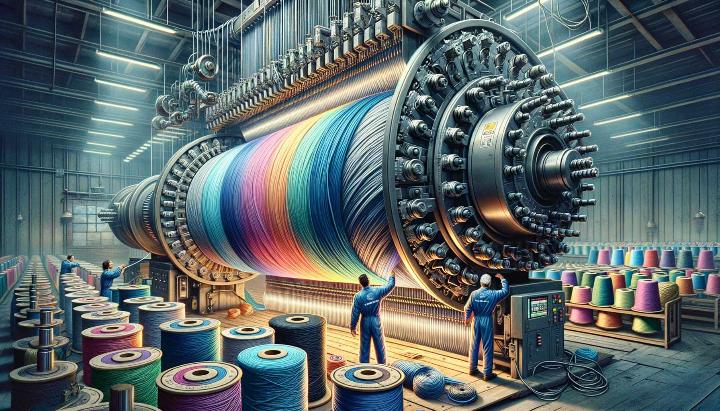

Have you ever wondered why some ropes seem to possess an almost superhuman strength? The secret lies in the intricate world of double braid rope core strength techniques. As a leading manufacturer of high-quality ropes, we at iRopes have delved deep into the science and art of crafting ropes that push the boundaries of performance.

Imagine a rope that can withstand the crushing forces of an offshore oil rig, yet remain flexible enough for a climber to trust their life to it. That's the power of mastering double braid rope core strength. In this blog post, we'll unravel the mysteries behind these remarkable engineered products, exploring everything from the braided core that forms their backbone to the cutting-edge materials like nylon and polyester that give them their extraordinary capabilities.

Whether you're a wholesale customer seeking the perfect rope solution for your industry or simply curious about the technology behind the ropes you use every day, this post will equip you with the knowledge to appreciate and select the right double braid pulling rope for your needs. From the intricacies of rope construction to real-world applications that showcase their incredible strength, we'll cover it all. So, are you ready to dive into the world of double braid ropes and discover how they're revolutionising industries across the globe?

Understanding Double Braid Rope Structure

As a rope enthusiast, I've always been fascinated by the intricate design of double braid ropes. These marvels of engineering are like the unsung heroes of the rope world, quietly supporting our adventures and industries with their remarkable strength and versatility.

Have you ever wondered what gives double braid ropes their exceptional performance? Let's dive into the heart of their structure and uncover the secrets behind their strength.

Composition of Double Braid Rope

At its core (pun intended), a double braid rope consists of two main components: an inner core and an outer cover. This dynamic duo works in harmony to create a rope that's greater than the sum of its parts.

- Inner hollow braid core: This is the powerhouse of the rope, providing the majority of its strength and load-bearing capacity.

- Outer hollow braid cover: Acting as a protective shield, the cover guards the core against abrasion and UV damage while contributing to the rope's overall strength.

The magic happens in the braiding process. Both the core and cover are braided separately, then interwoven to create a unified structure. This braid-on-braid construction allows for even load distribution throughout the rope, a key factor in its impressive performance.

Benefits and Applications of Double Braid Rope

The unique structure of double braid ropes offers a range of advantages that make them a top choice for various applications:

- Superior strength-to-weight ratio: Double braid ropes pack a lot of punch in a relatively lightweight package.

- Excellent flexibility: The braided construction allows for easy handling and knot-tying.

- Impressive durability: The outer cover protects the core, extending the rope's lifespan.

From marine environments to industrial settings, double braid ropes shine in applications where reliability is paramount. I've seen them in action during sailing expeditions, where their strength and flexibility make them ideal for halyards and sheets.

But the choice of material can significantly impact a double braid rope's performance. Let's explore some common materials:

- Polyester: Offers high strength and low stretch, perfect for marine applications.

- Nylon: Provides excellent shock absorption, making it ideal for mooring lines.

- HMPE (High Modulus Polyethylene): Boasts incredible strength-to-weight ratio, often used in high-performance scenarios.

Understanding the structure and composition of double braid ropes is just the beginning. In the next section, we'll delve deeper into the factors that influence their core strength. Are you ready to unravel more rope mysteries? Let's continue our journey into the world of double braid ropes!

Factors Influencing Double Braid Rope Core Strength

As we delve deeper into the world of double braid ropes, it's crucial to understand the factors that influence their core strength. Having worked with these ropes for years, I've come to appreciate the intricate balance of elements that contribute to their remarkable performance. Let's unravel the mystery together, shall we?

Material Composition and Rope Construction

The heart of a double braid rope's strength lies in its core, and the material used plays a pivotal role. I remember testing different rope materials during a rigging workshop, and the results were eye-opening.

- Nylon: Known for its excellent elasticity and shock absorption. It's perfect for dynamic loading situations, like mooring lines where sudden jerks are common.

- Polyester: Offers high strength with minimal stretch. I've found it ideal for applications requiring dimensional stability, such as sailboat halyards.

- HMPE (High Modulus Polyethylene): This lightweight champion boasts an incredible strength-to-weight ratio. It's a game-changer for high-performance scenarios where every gram counts.

But it's not just about the material. The way these fibres are woven together significantly impacts the rope's core strength. Have you ever wondered why some ropes feel more supple than others?

Did You Know?

The braiding technique and strand count can dramatically affect a rope's strength and flexibility.

Tighter braids generally result in stronger ropes, but they can be less flexible. Looser braids, on the other hand, offer more flexibility but might compromise on strength. It's all about finding the right balance for your specific needs.

Environmental and Usage Factors

Now, let's talk about the external factors that can make or break your rope's performance. I once witnessed a perfectly good climbing rope fail prematurely due to prolonged UV exposure - a harsh reminder of the importance of environmental considerations.

- Temperature and moisture: Extreme heat can weaken synthetic fibres, while moisture can lead to mildew and rot in natural fibre ropes.

- UV exposure: The sun's rays can degrade rope fibres over time, reducing strength and flexibility.

- Chemical exposure: Certain chemicals can react with rope materials, potentially compromising their integrity.

The type of load your rope endures also plays a crucial role. Static loads (constant weight) and dynamic loads (sudden impacts) affect ropes differently. It's essential to choose a rope that can handle the specific stresses of your application.

Understanding these factors is key to selecting and maintaining the right double braid rope for your needs. Remember, a rope is only as strong as its weakest point - whether that's in its material, construction, or how it's cared for.

Have you ever experienced unexpected rope performance in challenging conditions? Share your stories in the comments below - I'd love to hear about your experiences and insights!

Maximizing Double Braid Pulling Rope Performance

When it comes to double braid pulling ropes, optimizing performance is crucial for safety and efficiency. As someone who's spent years working with these ropes in various conditions, I've learned that maximizing their potential is both an art and a science. Let's dive into the techniques that can help you get the most out of your double braid rope.

Selecting the Right Double Braid Rope

Choosing the perfect double braid rope is like finding the right dance partner - it needs to match your specific needs and work in harmony with your application. Here's what to consider:

- Material matters: Double braid polyester rope offers high strength and low stretch, making it ideal for marine applications where dimensional stability is key. On the other hand, nylon provides excellent shock absorption and abrasion resistance, perfect for dynamic loading situations.

- Strength vs. flexibility: Consider the balance between these two factors. A rope with higher strength might sacrifice some flexibility, and vice versa. Think about your specific needs - do you need a rope that can handle sharp bends, or one that can withstand heavy loads?

- Diameter and length: These factors directly impact the rope's maximum load-bearing capacity. Always choose a rope that exceeds your required working load limit for an added safety margin.

For a deeper exploration of the performance advantages of specific materials, such as polyester and nylon in pulling ropes, learn more about double braid nylon anchor rope.

Remember: The braid angle of a double braid rope affects its characteristics. A tighter braid typically offers more strength, while a looser braid provides more flexibility.

Proper Handling and Maintenance Techniques

Even the best double braid pulling rope won't perform optimally without proper care. Here are some tips I've learned over the years:

- Maintain uniform tension: When using your rope, ensure the load is evenly distributed. Uneven tension can lead to weak spots and premature wear.

- Master the art of coiling: Proper coiling and uncoiling techniques prevent kinks and tangles, which can compromise rope strength. I always coil my ropes in a figure-eight pattern to avoid twists.

- Store with care: Keep your ropes in a cool, dry place away from direct sunlight and chemicals. UV exposure can degrade synthetic fibres over time.

- Clean regularly: Rinse your ropes with fresh water after use, especially if exposed to salt water or dirt. Allow them to air dry completely before storage.

Regular inspections are crucial. Run the rope through your hands, feeling for any inconsistencies in texture or diameter. Look for signs of wear, cuts, or abrasions. If you spot any issues, it's better to retire the rope early than risk a failure.

For more information on splicing techniques that enhance rope durability, learn about splice knot techniques that could significantly impact your rope's performance.

Advanced Splicing Methods for Optimal Strength

One technique that's truly revolutionized my rope work is the eye splice. This method can significantly enhance your double braid rope's strength and versatility. Here's why it's a game-changer:

- Increased breaking strength: A properly executed eye splice can retain up to 90% of the rope's original breaking strength, far superior to knots.

- Versatility: Eye splices create secure attachment points for various applications, from mooring to lifting operations.

- Longevity: Spliced ends are less prone to wear and unravelling compared to knotted ends.

Learning to create a proper eye splice takes practice, but it's a skill well worth mastering. Start with smaller diameter ropes and work your way up as you gain confidence.

By focusing on these techniques - selecting the right rope, maintaining it properly, and utilizing advanced splicing methods - you'll be well on your way to maximizing your double braid pulling rope performance. Remember, a well-cared-for rope isn't just about efficiency; it's about safety too. For a detailed guide to mastering double braid ropes, you might find that splice techniques for double braid rope are worth mastering, ensuring both strength and reliability are optimized. Have you tried any of these techniques? I'd love to hear about your experiences in the comments below!

Real-World Applications of Double Braid Rope Core Strength

As we've explored the intricacies of double braid rope construction and its impressive core strength, it's time to see how these ropes perform in real-world scenarios. I've had the privilege of witnessing double braid ropes in action across various industries, and their performance never ceases to amaze me.

Case Studies in Marine and Climbing Industries

Let's dive into some concrete examples where double braid rope core strength truly shines:

- Marine Application: Offshore Oil Rig Mooring - I once observed a massive offshore oil rig using double braid polyester ropes for its mooring system. The ropes, each with a diameter of 96mm, were capable of withstanding loads up to 1,000 tonnes. Their low stretch properties and resistance to creep made them ideal for maintaining the rig's position in challenging sea conditions.

- Sailing: America's Cup Rigging - During the last America's Cup, I noticed the teams using high-performance double braid ropes made with Dyneema® fibres for their running rigging. These ropes offered an incredible strength-to-weight ratio, allowing for faster sail handling and improved overall performance.

- Climbing: Big Wall Expeditions - On a recent expedition to Yosemite, I watched climbers tackling El Capitan using double braid dynamic ropes. These ropes provided excellent shock absorption for potential falls while maintaining durability against the abrasive granite surfaces.

In each of these cases, the core strength of double braid ropes played a crucial role in ensuring safety and performance. But how do they stack up against other rope constructions?

Comparing Double Braid to Other Rope Constructions

To truly appreciate the advantages of double braid ropes, let's compare them to other common rope types:

| Rope Type | Strength | Flexibility | Durability | Best For |

|---|---|---|---|---|

| Double Braid | Excellent | High | Very Good | Marine, Climbing, Industrial |

| Kernmantle | Very Good | High | Good | Climbing, Rescue Operations |

| Three-Strand Twisted | Good | Moderate | Good | General Purpose, Mooring |

| Braided (Single) | Good | Very High | Moderate | Sailing, General Purpose |

As you can see, double braid ropes offer a unique combination of strength, flexibility, and durability that makes them ideal for a wide range of applications. Their core strength is particularly advantageous in situations where high tensile strength and low stretch are crucial.

For instance, in marine applications, the core strength of double braid ropes allows them to maintain their integrity even under constant tension and exposure to harsh elements. In climbing scenarios, the balance between strength and flexibility provides climbers with confidence in their equipment while allowing for smooth rope handling.

Did you know? The braiding technique used in double braid ropes allows for better load distribution throughout the rope, contributing to its overall strength and durability.

As we wrap up our exploration of double braid rope core strength, I hope you've gained a deeper appreciation for these remarkable engineered products. Whether you're a professional in the marine or climbing industry, or simply someone who relies on ropes for various tasks, understanding the capabilities of double braid ropes can help you make informed decisions about your equipment.

Have you had any experiences with double braid ropes in challenging situations? I'd love to hear your stories in the comments below. And remember, when it comes to rope selection, always prioritise safety and choose the right tool for the job!

```htmlMastering the techniques for enhancing double braid rope core strength is essential for anyone relying on ropes for both demanding and everyday applications. This guide delves into the braided core's composition, emphasising its crucial role in achieving remarkable strength and stability. Key factors like material choice, braiding technique, and environmental influences are explored to help optimise double braid pulling rope performance. Techniques such as proper selection, maintenance, and advanced splicing methods can significantly enhance safety and efficiency in industrial, commercial, and recreational settings. By understanding these elements, you can make informed choices about double braid rope, whether using nylon, polyester, or woven rope, to suit your specific needs.

Unlock the Potential of Your Double Braid Rope

Complete the form above to connect with our experts at iRopes and discover how tailored solutions can improve your rope handling practices. Embrace the strength and versatility of double braid ropes for superior performance across various scenarios.

```