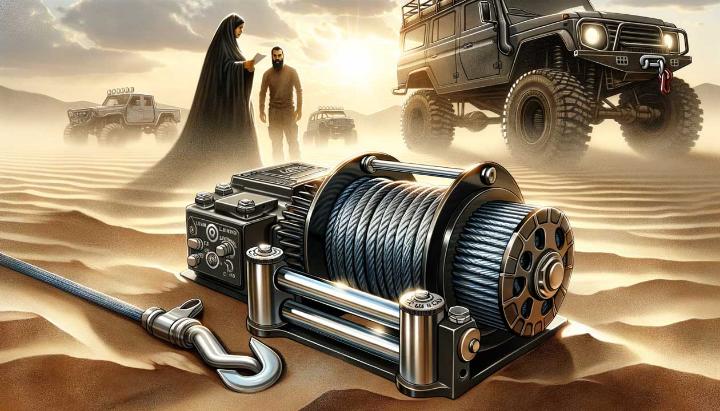

Have you ever found yourself in a sticky situation, your 4x4 bogged down in unforgiving terrain, wishing for a miracle? Enter the unsung hero of off-road adventures: the winch rope. But not just any rope – we're talking about the game-changing synthetic winch rope that's revolutionising the way we conquer the great outdoors.

For years, steel cables have been the go-to for winching operations. But what if I told you there's a lighter, stronger, and safer alternative that's taking the off-road world by storm? At iRopes, we've seen firsthand how synthetic winch ropes are outperforming their steel counterparts in nearly every aspect.

In this post, we'll dive deep into the world of winch rope guides and explore why they're quickly becoming the preferred choice for savvy off-roaders and industry professionals alike. From superior flexibility to enhanced safety features, we'll uncover the myriad advantages that make synthetic winch ropes the smart choice for your next adventure or industrial application.

So, buckle up and get ready to discover how the right winch rope can not only get you out of a tight spot but also revolutionise your entire approach to winching. Trust us, by the end of this read, you'll be wondering why you ever considered anything else.

Winch Rope Flexibility: Superior Performance vs Steel Cable

When it comes to winching operations, flexibility is a game-changer. As an off-road enthusiast who's spent countless hours navigating tricky terrains, I can't stress enough how crucial a flexible winch line can be. Let's dive into why synthetic winch ropes are stealing the show from their steel counterparts.

Synthetic Winch Ropes: Unmatched Flexibility and Handling

Have you ever tried to wrangle a steel cable in freezing conditions? It's not a pleasant experience, I can tell you that! Synthetic winch ropes, especially those made from HMPE (High-Modulus Polyethylene), offer a level of flexibility that's simply unmatched. These ropes bend and flex with ease, making them a joy to handle in any weather.

- Superior manoeuvrability: Synthetic ropes can be easily guided around obstacles, a godsend when you're stuck in a tight spot.

- Lightweight champion: The reduced weight of synthetic ropes means less strain on your winch and vehicle, improving overall performance.

- Safety first: Unlike steel cables, synthetic ropes don't store energy, reducing the risk of dangerous whiplash if they break.

Steel Cable Limitations: Understanding Reduced Flexibility

Now, don't get me wrong - steel cables have their place. They're tough as nails and can handle abrasive environments like a champ. But when it comes to flexibility, they fall short. Steel cables are inherently stiff, which can lead to some frustrating situations:

- Kinking concerns: Steel cables are prone to kinking, which can weaken the line and create safety hazards.

- Storage struggles: The rigidity of steel makes it challenging to coil and store compactly, eating up valuable space in your rig.

- Handling hardships: Ever tried to handle a steel cable without gloves? It's a recipe for cuts and scrapes, mate!

In my years of off-roading, I've found that the superior flexibility of synthetic winch ropes translates to smoother, safer, and more efficient winching operations. Whether you're a weekend warrior or a seasoned pro, the ease of handling and versatility of synthetic ropes can make a world of difference when you're out on the trails.

So, next time you're gearing up for an adventure, consider making the switch to a synthetic winch rope. Your hands (and your winch) will thank you!

Winch Rope Guide Systems: Enhancing Safety and Efficiency

As an avid off-roader and winch enthusiast, I've seen firsthand how crucial a reliable winch rope guide system can be. These nifty devices have revolutionised the way we approach winching operations, making them safer and more efficient than ever before. Let's dive into why these systems are becoming a must-have for serious winch users.

Key Features of Advanced Winch Rope Guides

Modern winch rope guide systems are a far cry from the basic setups of yesteryear. They're engineered to perfection, with features that'll make you wonder how you ever managed without them. Here's what sets them apart:

- Precision fairleads: These guide the rope onto the drum with minimal friction, reducing wear and tear significantly.

- Anti-chafe rollers: Smooth rollers ensure your rope glides effortlessly, preventing those frustrating snags and tangles.

- Durable construction: Made from high-grade materials like aluminium or stainless steel, these guides are built to last in the harshest conditions.

Safety Benefits of Modern Winch Rope Systems

Safety should always be your top priority when winching, and that's where these guide systems really shine. They offer a range of benefits that can help prevent accidents and extend the life of your equipment:

- Prevent rope jumping: The guide keeps your rope neatly aligned, stopping it from leaping off the drum during high-tension situations.

- Even winding: By ensuring the rope lays flat and even on the drum, you're reducing the risk of damage and improving overall performance.

- Reduced wear and tear: Less friction means less damage to your rope over time, saving you money and potential headaches down the track.

Remember, folks, a 2:1 safety factor is recommended for synthetic winch ropes. This means your rope's breaking strength should be at least double the maximum load you plan to winch. It's not just a suggestion - it's a crucial safety measure that could save your hide in a sticky situation.

Improving Operational Efficiency with Guide Technology

Efficiency is the name of the game when you're out on the trails, and a quality winch rope guide system can make all the difference. Here's how:

- Faster recovery times: With smooth operation and reduced tangling, you'll be back on track in no time.

- Extended rope life: Proper guiding means less abrasion and damage, keeping your rope in top condition for longer.

- Increased pulling power: By reducing friction and ensuring even spooling, you're maximising your winch's pulling capacity.

So, next time you're gearing up for an adventure, give some serious thought to your winch rope guide system. It's not just about having the right tools - it's about using them smartly and safely. Trust me, your future self will thank you when you're effortlessly winching out of that mud pit while your mates are still struggling!

Synthetic Winch Ropes: A Durable and Lightweight Alternative

As an off-road enthusiast who's seen my fair share of recovery situations, I can't stress enough how game-changing synthetic winch ropes have been for the 4x4 community. These modern marvels have revolutionised the way we approach winching, offering a host of benefits that leave traditional steel cables in the dust.

Advantages of Synthetic Ropes Over Steel Cables

When it comes to strength-to-weight ratio, synthetic winch ropes are in a league of their own. I remember the first time I hefted a synthetic rope - it was like picking up a feather compared to its steel counterpart! But don't let the lightweight fool you; these ropes pack a serious punch.

- Unbeatable strength: High-performance materials like HMPE and Dyneema offer incredible tensile strength while weighing a fraction of steel cables.

- Safety first: Unlike steel cables that can store energy and become lethal projectiles if they snap, synthetic ropes simply fall to the ground, dramatically reducing the risk of injury.

- Easy handling: The lightweight nature of synthetic ropes makes them a breeze to manoeuvre, especially in tight spots or when you're knee-deep in mud.

- Corrosion-resistant: Say goodbye to rust and corrosion worries. These ropes laugh in the face of water, salt, and harsh weather conditions.

Choosing the Right Synthetic Winch Rope for Your Needs

Selecting the perfect synthetic winch rope isn't a one-size-fits-all affair. It's crucial to consider your vehicle's weight and your winch's capacity to ensure you're getting the right tool for the job. Here's a quick guide to help you make an informed decision:

- Strength ratings matter: Always opt for a rope with a breaking strength at least 1.5 times your winch's rated line pull. For example, a 9,000 lb winch needs a rope with at least a 13,500 lb breaking strength.

- Size it right: Match the rope's diameter to your winch drum and fairlead. Common sizes range from 3/8" to 1/2" for most off-road applications.

- Consider the coating: Look for ropes with UV-resistant coatings to extend their lifespan, especially if you're in a sunny climate.

When it comes to installation and maintenance, synthetic ropes are surprisingly forgiving. However, a few simple tips can significantly extend your rope's life:

- Break it in gently: After installation, spool the rope under light tension to ensure even layering on the drum.

- Keep it clean: A quick rinse with fresh water after muddy adventures can prevent abrasive particles from damaging the fibres.

- Inspect regularly: Check for signs of wear, especially near the hook and fairlead, and don't hesitate to replace if you spot significant fraying.

From my experience, brands like Warn, Spydura, and Dyneema have consistently delivered top-notch performance across various vehicle types. Remember, investing in a quality synthetic winch rope isn't just about performance - it's about peace of mind when you're out exploring the great unknown.

Have you made the switch to synthetic winch ropes yet? If not, what's holding you back? Trust me, once you experience the difference, you'll wonder how you ever managed without them!

Customization Options for Application-Specific Optimization

As an experienced winch rope manufacturer, I've seen firsthand how customization can make or break a winching operation. Let's dive into the world of tailored winch ropes and explore how these bespoke solutions can revolutionise your lifting and pulling tasks.

Tailoring Winch Ropes to Specific Requirements

When it comes to winch ropes, one size definitely doesn't fit all. The beauty of modern synthetic ropes lies in their incredible versatility and adaptability. Here's how customization can take your winching game to the next level:

- Material selection: From UHMWPE to Dyneema, each material offers unique properties. We can choose the perfect blend for your specific needs, whether it's ultimate strength, abrasion resistance, or flexibility.

- Diameter and length: Fine-tuning these parameters ensures your rope fits perfectly with your winch and meets your load requirements. It's like getting a tailored suit for your winch!

- Color coding: This isn't just about aesthetics. Custom colors can help with safety protocols, quick identification, or even branding for commercial applications.

Enhancing Performance with Protective Coatings

One of the most exciting developments in winch rope technology is the ability to add specialized coatings. These aren't just fancy add-ons; they're game-changers for performance and longevity:

- UV protection: A must-have for ropes exposed to harsh sunlight, preventing degradation and extending lifespan.

- Abrasion-resistant coatings: Perfect for rocky terrains or industrial applications where the rope might face constant friction.

- Water-repellent treatments: Ideal for marine applications or wet environments, these coatings prevent water absorption and reduce the risk of freezing in cold climates.

I once worked with a mining company that needed a winch rope for their harsh, abrasive environment. By combining a high-strength UHMWPE core with a specialized abrasion-resistant coating, we created a rope that outlasted their previous steel cables by a factor of three. It's these kinds of tailored solutions that really showcase the power of customization.

Optimizing for Specific Applications

Every industry has its unique challenges, and that's where application-specific optimization really shines. Here are a few examples I've encountered:

- Off-road recovery: We developed a rope with a unique core-and-jacket construction, providing excellent shock absorption for those sudden jerks during vehicle recovery.

- Marine winching: By incorporating buoyant materials and salt-resistant coatings, we created ropes that float and resist corrosion in harsh marine environments.

- Forestry operations: High visibility colors combined with cut-resistant fibers proved ideal for logging operations, improving safety and durability.

Remember, the key to successful customization is understanding your specific needs. What works brilliantly in one scenario might be suboptimal in another. That's why we always recommend consulting with winch rope experts who can guide you through the customization process.

Have you considered how a customized winch rope could improve your operations? Whether you're dealing with extreme temperatures, abrasive environments, or specialized lifting requirements, there's likely a tailored solution waiting to be discovered. Don't hesitate to reach out and explore the possibilities – your perfect winch rope might be just a conversation away!

Explore the Benefits of Winch Rope Over Steel Cable

Winch ropes offer significant advantages over traditional steel cables, including superior flexibility, enhanced safety with winch rope guide systems, and durability. Unlike steel cables, synthetic winch ropes are easier to handle, don't kink, and are corrosion-resistant, making them a lightweight and reliable alternative. Customization options like material choice, diameter, and protective coatings ensure that each rope meets specific application needs. Investing in a quality winch rope and a proper rope guide can drastically improve the efficiency and safety of your lifting and pulling operations.

To find the perfect winch rope solution for your needs, please fill in the inquiry form above. We're here to help you leverage the benefits and efficiencies of modern synthetic winch ropes in your operations.