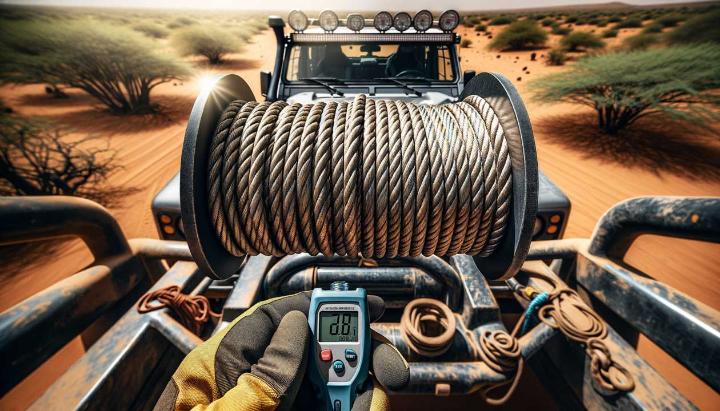

Have you ever found yourself in a precarious off-road situation, relying solely on your winch cable to pull you out of trouble? The strength of that cable could mean the difference between a successful recovery and a dangerous predicament. That's why understanding 3/8 winch cable strength is crucial for any serious off-road enthusiast or professional.

In this comprehensive guide, we'll dive deep into the world of winch cables, exploring the intricacies of 3/8 winch cable strength, decoding winch cable strength charts, and comparing 3/8 and 3/16 winch cable strength. But we're not just talking numbers here – we're talking about your safety and peace of mind in challenging situations.

At iRopes, we've made it our mission to produce high-strength winch cables that exceed industry standards. Our commitment to quality isn't just talk – it's backed by rigorous testing and comprehensive reports provided with every cable. Whether you're tackling treacherous terrain or handling heavy-duty industrial applications, you'll discover why iRopes' winch cables are the go-to choice for those who demand the best.

Ready to unlock the secrets of winch cable strength and make informed decisions about your recovery gear? Let's get started on this journey to safer, more effective winching.

Understanding 3/8 Winch Cable Strength Basics

When it comes to off-road recovery and heavy-duty winching, understanding the strength of your winch cable is crucial. Let's dive into the world of 3/8" winch cables and explore why their strength matters so much.

Breaking Strength of 3/8 Winch Cables

Breaking strength is the maximum load a winch cable can handle before failing. For 3/8" cables, this can vary significantly based on the material used. Here's a quick rundown:

- Steel cables: Typically offer a breaking strength of around 14,400 lbs.

- Synthetic ropes: Can reach up to 20,000 lbs breaking strength.

- iRopes high-performance synthetic lines: Boast industry-leading strength, often exceeding 20,000 lbs.

Remember, these figures represent maximum loads. For safe winching, always work well below these limits.

Synthetic vs Steel Winch Cables

The choice between synthetic and steel cables can significantly impact your winching experience. Here's why many off-road enthusiasts are making the switch to synthetic:

- Weight: Synthetic ropes are significantly lighter, reducing overall vehicle weight.

- Safety: They store less energy under tension, making them safer if they break.

- Flexibility: Easier to handle and less likely to develop memory.

- Durability: Resistant to corrosion and UV damage with proper care.

While steel cables have their place, the advantages of synthetic ropes are hard to ignore, especially when you consider the high-strength options offered by iRopes.

Advantages of High-Strength Winch Cables from iRopes

At iRopes, we're committed to providing top-tier winch cables that exceed industry standards. Here's why our high-strength cables stand out:

- Superior breaking strength: Our 3/8" synthetic ropes often surpass 20,000 lbs breaking strength.

- Rigorous testing: Each cable undergoes comprehensive testing, with reports provided to ensure reliability.

- Customization options: We can tailor cables to your specific needs, whether it's for off-road adventures or industrial applications.

- Quality assurance: Backed by ISO 9001 certification, our manufacturing process ensures consistent, high-quality products.

Choosing the right winch cable is about more than just strength - it's about confidence in your equipment when you need it most. With iRopes, you're not just getting a cable; you're investing in peace of mind for your toughest recoveries.

Remember: Always inspect your winch cable before use and replace it if you notice any signs of wear or damage. Your safety depends on it!

Exploring the Winch Cable Strength Chart

As an off-road enthusiast, I've learned that understanding winch cable strength charts is crucial for safe and effective winching. Let's dive into why these charts are so important and how to use them effectively.

Purpose and Benefits of Winch Cable Strength Charts

Winch cable strength charts are like a roadmap for your recovery operations. They provide vital information about the capabilities and limitations of your winch cable, helping you make informed decisions during challenging situations.

- Safety first: These charts help prevent overloading, reducing the risk of cable failure and potential injuries.

- Performance optimization: Understanding your cable's strength allows you to maximize its effectiveness without compromising safety.

- Proper equipment selection: Charts guide you in choosing the right cable for your specific winch and intended use.

Key Components of a Winch Cable Strength Chart

A comprehensive winch cable strength chart typically includes:

- Cable diameter: Usually ranging from 3/16" to 1/2" for most off-road applications.

- Breaking strength: The maximum load a cable can withstand before failing.

- Working load limit (WLL): Generally 1/3 to 1/5 of the breaking strength, representing the safe working load.

- Material type: Typically steel or synthetic, each with unique strength characteristics.

- Construction: Such as 7x19 for steel cables or 12-strand for synthetic ropes.

Interpreting and Applying Chart Data

To make the most of your winch cable strength chart:

- Identify your cable: Match your cable's specifications to the chart.

- Check the breaking strength: This is your absolute maximum load, but never plan to reach it.

- Calculate the working load limit: Divide the breaking strength by 3 to 5 for a safe working load.

- Consider environmental factors: Wet conditions, abrasion, and UV exposure can reduce strength.

Remember, these charts are guidelines. Always err on the side of caution and consider factors like dynamic loading and shock loads, which can significantly increase the stress on your cable.

Pro Tip: Never exceed your winch's rated capacity, even if your cable's working load limit is higher. Your winch is the weakest link in the recovery system!

At iRopes, we provide detailed strength charts and comprehensive test reports with all our winch cables. This transparency ensures you can trust our products for even the toughest recovery situations. Have you ever found yourself in a sticky situation where understanding your winch cable's strength made all the difference? Share your experience in the comments below!

Comparing 3/8 vs 3/16 Winch Cable Strength

When it comes to winching, choosing the right cable diameter can make all the difference between a successful recovery and a frustrating experience. Let's dive into the world of 3/8" and 3/16" winch cables, exploring their strengths and ideal applications.

Breaking Strength Comparison

The most crucial factor in winch cable performance is its breaking strength. Here's how 3/8" and 3/16" cables stack up:

- 3/16" synthetic winch rope: Typically offers a breaking strength of around 4,800 lbs.

- 3/8" Classic winch line: Boasts a significantly higher breaking strength of approximately 17,600 lbs.

It's clear that the 3/8" cable provides a substantial strength advantage. But that's not the whole story. Let's break it down further:

While the 3/8" cable offers superior strength, the 3/16" option shouldn't be overlooked. Its lower weight and increased flexibility can be advantageous in certain situations. The key is understanding your specific needs and choosing accordingly.

Practical Applications and Recommendations

So, how do you decide between 3/8" and 3/16" winch cables? Consider these factors:

- Vehicle weight: Heavier vehicles typically require the higher strength of a 3/8" cable.

- Terrain: For extreme off-roading with challenging recoveries, the 3/8" cable provides extra peace of mind.

- Frequency of use: If you're an occasional user, the lighter 3/16" cable might suffice.

- Storage space: 3/16" cables take up less room on your winch drum, allowing for longer cable lengths.

In my experience, most off-road enthusiasts prefer the 3/8" cable for its versatility and strength. However, I've seen plenty of successful recoveries with 3/16" cables on lighter vehicles.

Pro Tip: Always consider your winch's capacity when choosing a cable. A 3/8" cable won't help if your winch isn't rated to handle its full strength!

At iRopes, we offer high-quality synthetic winch lines in both 3/8" and 3/16" diameters. Our 3/8" Classic winch line provides industry-leading strength, while our 3/16" option offers excellent performance for lighter applications. Both come with comprehensive test reports, ensuring you can trust their performance when it matters most.

Remember, the best winch cable is the one that meets your specific needs. Consider your vehicle, intended use, and recovery scenarios when making your choice. And always prioritize safety by using appropriate recovery gear and techniques.

Have you had experience with both 3/8" and 3/16" winch cables? We'd love to hear about your real-world comparisons in the comments below!

iRopes' Commitment to Quality and Testing

When it comes to winch cables, quality and reliability are non-negotiable. At iRopes, we've made it our mission to deliver products that not only meet but exceed industry standards. Let me take you behind the scenes of our rigorous manufacturing process and testing procedures that ensure every cable we produce is up to the task.

ISO 9001 Certification and Rope Testing Procedures

As an ISO 9001 certified manufacturer, we've implemented a comprehensive quality management system that permeates every aspect of our operations. But what does this mean for you, our valued customer?

- Consistency in quality: Our ISO 9001 certification ensures that every rope we produce meets the same high standards, batch after batch.

- Continuous improvement: We're constantly refining our processes to deliver better products and services.

- Customer focus: Your needs and expectations are at the heart of everything we do.

Our testing procedures go beyond the basics. We subject our ropes to an array of tests that simulate real-world conditions:

- Tensile strength testing: We push our ropes to their limits to determine their breaking point.

- Elongation tests: This helps us understand how the rope will perform under load.

- Abrasion resistance: We simulate harsh environments to ensure durability.

- UV exposure tests: Because we know your gear often sits in the sun for extended periods.

Ensuring Safety through Rigorous Quality Control

Quality control isn't just a final checkpoint for us; it's woven into every step of our manufacturing process. Here's a glimpse into how we ensure the safety and reliability of every iRopes product:

- Raw material inspection: We source only the highest quality materials and inspect them thoroughly upon arrival.

- In-process checks: Our skilled technicians perform regular checks throughout the manufacturing process.

- Non-destructive testing: We use advanced techniques like ultrasound to detect any internal flaws without compromising the rope.

- Batch testing: Random samples from each batch undergo our full suite of tests to ensure consistency.

- Final inspection: Every single rope is visually inspected before packaging.

But we don't stop there. We believe in complete transparency, which is why we provide comprehensive test reports with every winch cable we sell. These reports give you a detailed look at the performance characteristics of your specific rope, empowering you to make informed decisions about its use and limitations.

Did you know? Our test reports include a unique identifier that allows you to trace your rope back to its specific production batch, giving you unparalleled peace of mind.

At iRopes, we're not just selling you a product; we're providing a promise of quality, backed by rigorous testing and unwavering commitment to safety. When you choose an iRopes winch cable, you're choosing peace of mind for your toughest recoveries.

Have you ever had to rely on a winch cable in a critical situation? How important was the quality of that cable to you? Share your experiences in the comments below – we'd love to hear your stories and how they've shaped your gear choices.

Discover the Strength and Reliability of iRopes Winch Cables

Understanding the 3/8 winch cable strength is crucial for effective off-road recovery. This blog explores the benefits of using high-strength winch cables from iRopes, backed by rigorous testing and comprehensive strength charts. We delve into the differences between 3/8 and 3/16 winch cables, highlighting their respective strengths and applications. iRopes' dedication to quality, evidenced by their ISO 9001 certification and thorough testing procedures, ensures you receive reliable and robust cables. For further information or to explore customised cable solutions, fill in the inquiry form above. Trust iRopes for durable winch cables with industry-leading strength and transparency through detailed test reports.