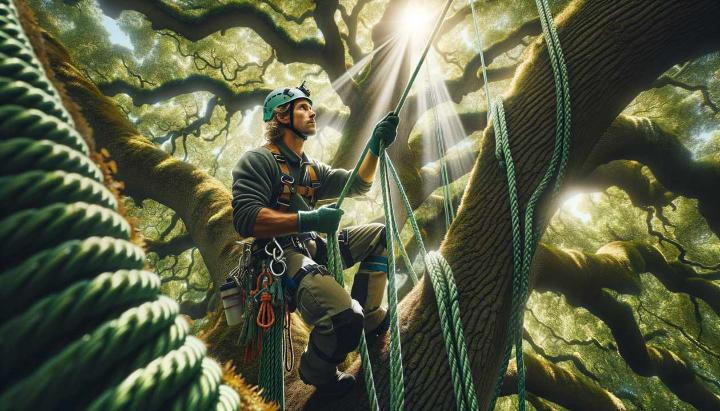

When it comes to tree work, having the right tools can make all the difference. Imagine tackling a towering gum tree without a reliable arborist bull rope - a recipe for disaster. Such ropes are indispensable in the world of arboriculture, playing a crucial role in everything from hauling equipment to safely lowering massive branches. But what makes an arborist bull rope truly effective, and how do you choose the right one for your specific needs?

In this post, we will delve into the essentials of arborist bull ropes, covering their top uses and the optimal materials to consider. Whether you’re a seasoned tree professional or just starting, understanding the importance of a dependable rope will enhance your safety and efficiency on the job. So, let's explore why selecting the right arborist bull rope near you is more than just a purchase - it’s an investment in precision, reliability, and safety.

Top Uses of Arborist Bull Rope

An arborist bull rope is a specialized, heavy-duty rope designed specifically for tree work and logging operations. These ropes are an essential tool for arborists, allowing them to perform challenging tasks safely and efficiently. But what exactly is a bull rope, and what are its primary uses?

What is an Arborist Bull Rope?

An arborist bull rope is a strong, durable rope made from high-quality materials like polyester or nylon. These ropes are designed to withstand tremendous loads, making them ideal for rigging and lowering heavy branches or even entire trees. One of the key features of a bull rope is its low stretch, which ensures minimal elongation under tension, providing better control and stability during operations.

Common Applications of Arborist Bull Ropes

- Rigging and lowering large branches: Bull ropes are essential for rigging and safely lowering large, heavy branches to the ground. They are used in conjunction with pulleys, blocks, and other rigging equipment to create mechanical advantage, allowing arborists to control the descent of the branches.

- Hauling tools and equipment into the tree canopy: Arborists often need to haul tools, chainsaws, and other equipment into the tree canopy. Bull ropes provide the strength and durability required for this task, ensuring the safe and secure transportation of gear.

- Assisting in tree climbing and positioning: Experienced arborists use bull ropes as climbing lines or to help position themselves securely within the tree canopy, allowing them to work efficiently and safely at great heights.

- Securing and stabilizing trees during removal or pruning: When removing or pruning large trees, bull ropes are used to secure and stabilize the tree, preventing it from falling in an uncontrolled manner and causing damage or injury.

Choosing the Right Arborist Bull Rope

With so many applications, it's crucial to choose the right arborist bull rope for the job. Here are some important factors to consider:

- Diameter and strength: The diameter and minimum breaking strength of the rope should be appropriate for the intended use. Heavier tasks like rigging large branches or securing trees may require ropes with a larger diameter and higher breaking strength.

- Stretch characteristics: Low-stretch ropes are preferred for most arborist applications as they provide better control and stability. However, in some cases, a slightly stretchy rope may be beneficial for shock absorption.

- Abrasion resistance: Since arborist ropes are subject to frequent contact with rough surfaces like bark and branches, choosing a rope with excellent abrasion resistance is crucial for longevity and safety.

- Splicing capabilities: The ability to splice the rope can be advantageous for creating eye terminations or joining multiple lengths, depending on the specific needs of the job.

When selecting an arborist bull rope, it's always best to consult experienced professionals or refer to product specifications to ensure you choose the right rope for your specific needs. With the proper rope and techniques, arborists can safely and efficiently tackle even the most challenging tree work projects.

How to Choose the Right Arborist Bull Rope

When it comes to tree work, having the right arborist bull rope can make all the difference. These specialized ropes are designed to withstand the rigors of the job, ensuring your safety and the success of every operation. But with so many options available, how do you choose the perfect one for your needs?

Understanding Bull Rope Types and Applications

Before diving into the selection process, it's essential to understand the different types of bull ropes and their applications. Two of the most common constructions are double-braid and kernmantle.

- Double-braid ropes are known for their exceptional strength and resistance to abrasion, making them ideal for rigging and lowering heavy loads. They're commonly used for tasks like tree removal, where their durability is crucial.

- Kernmantle ropes, on the other hand, feature a tightly braided sheath surrounding a core, providing a perfect balance of strength and flexibility. These ropes are often preferred for tree climbing and positioning, as they offer better grip and handling.

Depending on the specific task at hand, you may need a rope with different characteristics. For instance, tree removals might require a thicker, more robust rope, while tree pruning or climbing could benefit from a thinner, more flexible option.

Factors to Consider When Selecting an Arborist Bull Rope

When choosing an arborist bull rope, there are several key factors to consider:

- Rope strength: Ensure that the rope's minimum breaking strength is appropriate for the intended use. Heavier tasks, such as rigging large branches or securing entire trees, will require a higher breaking strength.

- Diameter: The rope's diameter plays a crucial role in handling and knot-tying. A thicker rope may be more challenging to work with, but it also offers increased durability and load-bearing capacity.

- Length: The length of the rope should be suitable for the job at hand. Too short, and you may not have enough reach; too long, and you'll have excess weight and bulk to manage.

- Splicing capabilities: If you plan to create eye terminations or join multiple rope lengths, look for ropes that can be easily spliced.

- Abrasion resistance: Since arborist ropes are constantly in contact with rough surfaces like bark and branches, excellent abrasion resistance is a must for longevity and safety.

Remember, consulting with experienced professionals or referring to product specifications is always a wise move. They can provide valuable insights and recommendations tailored to your specific needs and experience level.

Top-Rated Bull Ropes for Arborists

To help you get started, here are a few top-rated bull rope options that have earned praise from arborists around the world:

- Yale XTC 16 Arborist Rope: This double-braid polyester rope boasts an impressive 16-strand construction, offering exceptional strength and durability. Its low stretch and excellent abrasion resistance make it a favorite for rigging and lowering heavy loads.

- Bluewater Arborplex Climbing Line: This kernmantle rope is a go-to choice for tree climbing and positioning. Its tightly braided sheath and high-strength core provide the perfect balance of grip, flexibility, and durability.

- New England Ropes VX Series: Known for its versatility, the VX Series features a unique Vectran core that offers excellent strength-to-weight ratio and resistance to abrasion and UV exposure, making it suitable for various arborist tasks.

When it comes to investing in an arborist bull rope, remember to prioritize quality over cost. Reputable suppliers and manufacturers will ensure that you receive a product that meets industry standards and can withstand the demands of your work.

Choosing the right arborist bull rope is a crucial decision that can impact your safety, efficiency, and overall success on the job. By considering the factors we've discussed and seeking guidance from experienced professionals, you'll be well-equipped to tackle even the most challenging tree work projects with confidence and peace of mind.

Common Materials Used in Arborist Pulling Ropes

When it comes to arborist work, having the right rope is essential for safety and efficiency. But with so many options on the market, how do you choose the best materials for your pulling ropes? Well, worry no more, my fellow tree-climbing enthusiasts! Let's dive into the world of arborist rope materials and find the perfect fit for your needs.

Polyester and Nylon Ropes for Tree Work

When it comes to arborist pulling ropes, two materials reign supreme: polyester and nylon. These synthetic fibers have earned their place in the tree work industry due to their exceptional strength, durability, and versatility.

- Polyester ropes: If you're looking for a rope that's tough as nails and won't stretch under pressure, polyester is your go-to choice. These ropes are known for their high tensile strength, low stretch characteristics, and excellent resistance to abrasion – perfect for rigging and lowering those heavy branches with precision.

- Nylon ropes: When you need a rope that can handle a bit of shock and won't leave you hanging (literally), nylon is the way to go. These elastic ropes offer superior strength and shock absorption, making them ideal for tree climbing and positioning. Plus, their durability means they'll stick by your side for years to come. Learn more about the top benefits of nylon braid and double braid nylon rope.

Whether you're a seasoned pro or just starting your arborist journey, investing in high-quality polyester or nylon ropes is a no-brainer. These materials have been trusted by professionals for years, and it's easy to see why.

Choosing the Right Arborist Rope

Now that you know the key players in the arborist rope game, it's time to learn how to choose the right one for your needs. After all, not all tree work is created equal, and you'll want a rope that can handle the specific demands of your job.

- Consider the load: Are you rigging heavy branches or securing entire trees? If so, you'll need a rope with a higher breaking strength and larger diameter to handle the weight.

- Think about stretch: Do you prefer a rope that stays tight and stable, or one with a bit of give for shock absorption? Polyester ropes are low-stretch, while nylon offers more elasticity. When comparing options, read about nylon vs polyester: which kinetic recovery rope is best.

- Factor in the environment: Will your rope be exposed to harsh sunlight, chemicals, or extreme temperatures? Look for materials that can withstand these conditions without compromising their integrity.

Remember, safety should always be your top priority when selecting an arborist rope. Don't hesitate to consult with experienced professionals or refer to industry guidelines to ensure you're making the best choice for your needs.

With the right materials and proper techniques, you'll be well on your way to conquering even the most challenging tree work projects with confidence and peace of mind. So, grab your harness, lace up your boots, and let's get climbing!

Maintaining and Caring for Your Arborist Bull Rope

As an arborist, your bull rope is your lifeline – literally. It's the sturdy, reliable companion that keeps you safe and secure as you navigate through towering branches and tackle challenging tree work projects. But just like any piece of essential equipment, your bull rope requires proper care and maintenance to ensure its longevity and peak performance.

Neglecting your arborist bull rope can have serious consequences. Imagine being high up in a tree canopy, rigging a heavy branch, when your frayed and worn rope suddenly snaps. Not a pleasant thought, is it? That's why it's crucial to follow the recommended practices for cleaning, storing, and inspecting your bull rope regularly.

Cleaning and Washing Your Arborist Bull Rope

Tree work is a messy business, and your bull rope is bound to get caked with pitch, sap, dirt, and grime over time. Left unchecked, these contaminants can weaken the rope fibers and compromise its strength. To keep your bull rope in top condition, regular cleaning is a must.

- Hand-washing: For a thorough clean, opt for hand-washing your bull rope with a mild soap or rope cleaner. Avoid harsh detergents, as they can damage the rope fibers. Fill a tub or bucket with warm water, add the cleaning solution, and gently scrub the rope with a soft-bristled brush. Rinse thoroughly to remove any soap residue.

- Machine washing: Some manufacturers may recommend machine washing for their arborist bull ropes. If so, follow their instructions carefully, using a gentle cycle and mild detergent. Avoid washing your rope with other items, as the agitation could cause excessive wear.

- Drying: After washing, it's essential to dry your rope thoroughly. Hang it in a well-ventilated, shaded area, and allow it to air dry completely before storing or using it again. Moisture trapped inside the rope can lead to mildew and premature degradation.

Proper Storage and Handling of Bull Ropes

Proper storage is key to extending the lifespan of your arborist bull rope. Exposure to sunlight, chemicals, and moisture can accelerate the rope's deterioration, so it's crucial to store it in the right conditions.

- Storage area: Keep your bull rope in a cool, dry, and shaded area, away from direct sunlight and potential chemical spills. Ultraviolet rays and certain chemicals can break down the rope fibers over time, compromising their strength.

- Rope bag or container: Invest in a dedicated rope bag or container to store your bull rope. This will prevent tangles, snags, and accidental damage from other tools or equipment.

- Handling practices: Be mindful of how you handle your bull rope. Avoid dragging it across abrasive surfaces, running over it with vehicles, or subjecting it to excessive strain or shock loads. Treat it with care, and it will serve you well in return.

Regular inspections are also essential for maintaining the integrity of your arborist bull rope. Before each use, examine the rope carefully for signs of wear, damage, or fraying. Pay close attention to high-stress areas, such as splice points and areas that frequently come into contact with tree bark or rigging equipment.

Remember, a damaged or excessively worn bull rope is a safety hazard waiting to happen. Don't take chances – if you notice any significant signs of wear or damage, it's time to retire your trusty companion and invest in a new, high-quality arborist bull rope.

By following these simple yet crucial maintenance and care practices, you can ensure that your arborist bull rope remains a reliable and trustworthy partner throughout your tree work adventures, keeping you safe and secure as you conquer new heights. For more specific details on nylon ropes, check out the power of nylon pulling rope in tree work.

Understanding the vital role arborist bull rope plays in tree work is essential for any professional arborist. These ropes are indispensable for tasks such as rigging and lowering large branches, hauling tools, and assisting during tree climbing. When choosing the right arborist bull rope near me, consider factors like the rope's diameter, strength, and construction type—be it braided, twisted, or kernmantle. Additionally, it's crucial to understand the different materials like polyester, nylon, and Dyneema, each offering distinct advantages in arborist pulling rope applications. Regular maintenance, including proper storage and inspections for wear, will extend your rope's lifespan and ensure safety on the job.

Get the Perfect Arborist Bull Rope for Your Tree Work

Please fill in the form above to get more details and inquiries about acquiring high-quality arborist bull ropes tailored to your specific needs.