Imagine you're a naval officer, charged with a critical mission that requires utmost precision and attention to detail. The success of your operation hinges on the performance of your equipment, and one crucial component stands out: the winch rope for your rigid inflatable boat (RIB).

In the world of naval operations, a reliable and high-quality winch rope can mean the difference between a flawless execution and a catastrophic failure. That's where iRopes' fiber winch ropes come into play, offering a unique blend of strength, durability, and customization tailored for the boat rib needs of your naval crew.

As you prepare your rib boat for mission-critical scenarios, you'll discover that not all winch ropes are created equal. iRopes' expertise lies in understanding the intricate requirements of naval operations, offering solutions that cater to your specific rib boat winching demands.

Understanding Navy Rigid Inflatable Boats (RIBs)

What is a Navy RIB?

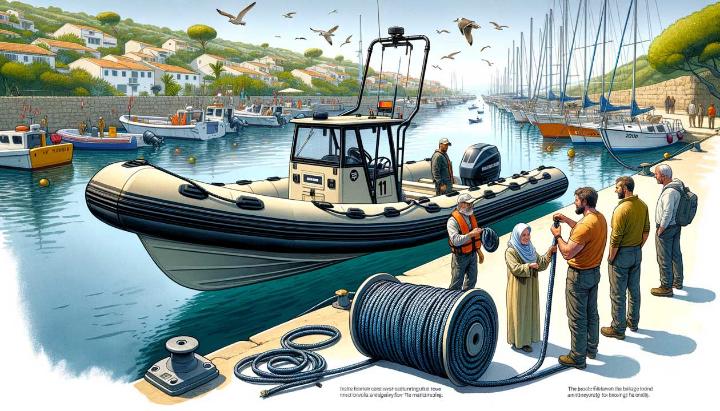

Rigid inflatable boats (RIBs), also known as rigid-hull inflatable boats (RHIBs), are versatile and robust watercraft extensively used by the U.S. Navy for various maritime operations. These high-speed, high-buoyancy vessels are designed to withstand extreme weather conditions, making them an indispensable asset for the Navy.

RIBs range in size from 4 to 18 meters in length, with models like the 11-meter Naval Special Warfare RIB serving as a prime example. Their unique design combines a rigid hull with inflatable collars or tubes, providing unparalleled stability, maneuverability, and seaworthiness.

Characteristics and Requirements of Navy RIBs

Navy RIBs are engineered to meet stringent performance requirements, enabling them to operate in heavy seas and high winds of up to 45 knots. Their rigid hull and inflatable collar/tube design provides a perfect combination of strength, durability, and buoyancy, making them virtually unsinkable.

In addition to their robust construction, Navy RIBs feature specialized components such as lifting bails, which facilitate launch and retrieval from Navy ships. These vessels are designed for a demanding service life, requiring regular maintenance to ensure optimal performance and crew safety.

Advantages and Disadvantages of Navy RIBs

The use of RIBs in Navy operations offers several advantages, including:

- Versatility: RIBs can be deployed for various missions, from SEAL insertion/extraction to marine interdiction operations.

- High Stability: The inflatable collar/tubes provide exceptional stability, even in rough seas.

- Maneuverability: RIBs are highly maneuverable, allowing for quick evasive actions and precise navigation.

- Seaworthiness: Their robust design ensures seaworthiness in challenging maritime environments.

However, it's important to acknowledge potential disadvantages or limitations, such as:

- Vulnerability to Punctures: The inflatable components can be susceptible to punctures, which may compromise the vessel's buoyancy.

- Increased Maintenance: Regular inspections and maintenance are crucial to ensure the longevity and reliability of RIBs.

By understanding the unique requirements, advantages, and potential drawbacks of Navy RIBs, the importance of selecting the right winch rope for these vessels becomes evident. A high-quality, durable, and reliable winch rope is essential for safe and efficient naval operations involving RIBs.

iRopes' Fiber Winch Ropes: The Ideal Solution for Your Winching Needs

When it comes to winching applications, traditional steel cables have long been the go-to choice. However, with advancements in materials and technology, fiber winch ropes have emerged as a superior alternative, offering numerous advantages over their steel counterparts.

At iRopes, we understand the unique demands of naval operations, and our fiber winch ropes are engineered to meet and exceed the rigorous requirements of a rib boat navy. Made from ultra-high-molecular-weight polyethylene (UHMWPE), our winch ropes boast exceptional strength, durability, and abrasion resistance, ensuring reliable performance even in the harshest marine environments.

Benefits of Fiber Winch Ropes

- Lightweight and Easy to Handle: Fiber winch ropes are significantly lighter than steel cables, making them easier to transport, deploy, and manage, especially in confined spaces aboard naval vessels.

- Increased Flexibility: Unlike their rigid steel counterparts, fiber ropes are highly flexible and less prone to kinking or developing rough edges, reducing the risk of damage to equipment and personnel.

- Enhanced Safety: Fiber winch ropes are less likely to cause injuries from burrs or sharp ends, providing a safer working environment for naval personnel.

- Resistance to Environmental Factors: Our UHMWPE winch ropes are naturally resistant to water, UV radiation, and other environmental factors, ensuring long-lasting performance and minimizing the need for frequent replacements.

Features of iRopes' Fiber Winch Ropes

At the core of our fiber winch ropes lies the exceptional strength and durability of UHMWPE, a high-performance material that outperforms traditional synthetic fibers. With breaking strengths ranging from 3,500 to 45,000 pounds, our winch ropes are designed to handle even the most demanding winching applications, ensuring reliable performance when it matters most.

But strength and durability are just the beginning. We offer custom design options to meet the specific needs of your rib boat navy, allowing you to choose from a range of diameters, lengths, colors, and construction types to suit your unique requirements.

Quality is of utmost importance at iRopes, and we subject our fiber winch ropes to extensive testing and quality control measures to ensure superior performance. Our products are meticulously crafted to comply with relevant naval standards and regulations, providing you with the peace of mind that your winching operations will be conducted safely and efficiently.

Advantages of Using iRopes' Fiber Winch Ropes for Rib Boat Navy

If you're part of a naval rib boat crew, you know that every operation demands the utmost precision and reliability. From high-speed maneuvers to delicate retrieval missions, the success of your mission often hinges on the performance of your equipment, including the winch ropes you rely on.

That's where iRopes' fiber winch ropes shine. Designed to meet the unique challenges of naval operations, our synthetic fiber ropes offer a range of advantages that make them the ideal choice for your rib boat navy.

Lightweight and High Strength Fiber Rope Benefits

One of the most significant benefits of our fiber winch ropes is their exceptional strength-to-weight ratio. Constructed from ultra-high-molecular-weight polyethylene (UHMWPE) fibers like Dyneema, these ropes pack an incredible punch, with breaking strengths ranging from 3,500 to 45,000 pounds, yet they're incredibly lightweight and easy to handle.

Imagine the difference this can make during critical operations. Lightweight ropes not only reduce the overall weight of your rib boat, improving fuel efficiency and maneuverability, but they also make it easier for your crew to deploy and manage the ropes, minimizing fatigue and enhancing operational efficiency.

And when it comes to demanding naval operations, the high strength of our fiber winch ropes is an invaluable asset. Whether you're hauling heavy equipment or securing critical loads, you can trust that our ropes will withstand the toughest challenges, ensuring the safety and success of your mission.

Safety and Minimal Recoil with Synthetic Rope Breakage

One of the most significant advantages of using fiber winch ropes is the enhanced safety they provide, especially in the event of a rope breakage. Unlike steel wire ropes, which can recoil violently and cause severe injuries, our synthetic fiber ropes have minimal recoil, minimizing the risk of damage and ensuring the safety of your crew.

But that's not all. Fiber ropes also don't store energy under load like their steel counterparts, making them inherently safer to handle and reducing the risk of accidents during high-tension operations.

And let's not forget about the abrasion resistance and shock absorption capabilities of our fiber winch ropes. These properties ensure that your ropes can withstand the harsh conditions of naval operations, from saltwater exposure to constant friction, without compromising their integrity or performance.

With iRopes' fiber winch ropes, you can rest assured that your crew and equipment are protected, even in the most demanding situations. After all, safety should never be compromised, especially in the high-stakes world of naval operations.

Choosing the Right Fiber Winch Rope for Your Rib Boat Navy

When it comes to naval operations involving rigid inflatable boats (RIBs), selecting the right winch rope is paramount. These versatile vessels face unique challenges and demanding conditions, making the choice of winch rope a critical factor in ensuring safe and efficient missions.

As a member of a naval rib boat crew, you understand the importance of having equipment that can withstand the rigors of the open seas and the unpredictable nature of your operations. That's why it's essential to choose a winch rope that not only meets but exceeds the stringent requirements of a rib boat navy.

Factors to Consider When Selecting Winch Rope

When it comes to selecting the right winch rope for your rib boat navy, there are several crucial factors to consider:

- Breaking Strength and Safety Margin: The breaking strength of a winch rope should be at least 1.5 to 2 times the winch's pulling capacity. This safety margin ensures that the rope can withstand the loads and stresses of naval operations without failure.

- Abrasion Resistance: In the harsh marine environment, winch ropes are constantly exposed to saltwater, UV radiation, and abrasive surfaces. A highly abrasion-resistant rope is essential to ensure longevity and prevent premature wear or failure.

- Stretch and Elongation: During winching operations, precise control is critical. A rope with minimal stretch or elongation characteristics is preferred, as excessive stretching can lead to loss of control and potential safety hazards.

- Weight and Ease of Handling: Lightweight and highly flexible ropes are easier to transport, deploy, and manage, especially in the confined spaces aboard naval vessels, enhancing operational efficiency and reducing crew fatigue.

- Cost-Effectiveness: While safety and performance are paramount, considering the cost-effectiveness of the winch rope is also essential, especially for large-scale naval operations with budgetary constraints.

By carefully evaluating these factors, you can ensure that the winch rope you choose is tailored to the specific requirements of your rib boat navy, providing the reliability and performance you need for successful missions.

Synthetic vs. Steel Winch Rope: Pros and Cons

When it comes to winch rope materials, the debate between synthetic fiber ropes and traditional steel cables is ongoing. Both options have their advantages and disadvantages, and it's essential to weigh them carefully before making a decision.

Synthetic fiber ropes, such as those made from high-performance materials like nylon or polyester, offer several benefits over steel cables:

- Lightweight and Easy to Handle: Synthetic ropes are significantly lighter than steel cables, making them easier to transport, deploy, and manage, especially in the confined spaces of naval vessels.

- Flexibility and Minimal Kinking: The flexible nature of synthetic ropes allows for smoother spooling and reduced risk of kinking or developing rough edges, which can damage equipment or cause injury.

- Resistance to Corrosion and UV Damage: Unlike steel, synthetic ropes are naturally resistant to corrosion from saltwater and UV degradation, ensuring a longer lifespan and reduced maintenance requirements.

To explore more about the benefits of synthetic winch ropes, check out our dedicated guide on how they unleash unrivaled performance for various applications here.

However, synthetic ropes also have some potential drawbacks to consider:

- Susceptibility to Abrasion: While synthetic ropes are generally abrasion-resistant, they can still be susceptible to wear and tear, especially when exposed to sharp or rough surfaces over time.

- Potential Degradation Over Time: Exposure to environmental factors like heat, chemicals, and UV radiation can accelerate the degradation of synthetic ropes, potentially compromising their strength and performance.

When it comes to steel cables, their main advantage is their exceptional strength and durability. However, they are also significantly heavier, more prone to kinking and damage, and susceptible to corrosion in marine environments.

For a broader comparison between fiber ropes and steel cables, you can read our detailed article on why synthetic rope often outperforms steel cable in various uses here.

Ultimately, the choice between synthetic fiber ropes and steel cables will depend on your specific operational requirements, budget considerations, and the unique challenges faced by your rib boat navy.

iRopes' Expert Guidance and Support

At iRopes, we understand the complexities involved in selecting the right winch rope for your rib boat navy. That's why we offer expert guidance and support to help you navigate the various options and make an informed decision.

Our team of experienced professionals will work closely with you to understand your specific requirements, operational conditions, and budget constraints. With our in-depth knowledge of rope materials, construction methods, and performance characteristics, we can recommend the optimal fiber winch rope solution tailored to your needs.

But our support doesn't stop there. We also provide comprehensive training and educational resources to ensure your crew is equipped with the knowledge and skills to properly handle, maintain, and care for your winch ropes, maximizing their lifespan and ensuring your operations run smoothly.

"With iRopes' expert guidance and support, you can rest assured that your rib boat navy will have the right winch rope solution for every mission, ensuring the safety and success of your operations."

At iRopes, we take pride in being more than just a rope manufacturer; we're your trusted partner in navigating the challenges of naval operations. With our commitment to quality, innovation, and customer support, you can trust that your rib boat navy will be equipped with the best winch rope solutions for years to come.

Choosing the right boat winch rope is essential for the safety and efficiency of your rib boat navy operations. iRopes' fibre winch ropes provide the perfect solution, featuring high-quality materials, custom designs tailored to a rib boat navy, and strict compliance with naval standards. These ropes offer enhanced safety, reduced maintenance, and improved operational efficiency, making them ideal for the unique challenges faced by a rib boat navy. With expert guidance and support, iRopes ensures you select the optimal winch rope for your needs, highlighted by successful case studies in naval applications.

Inquire About Our Customised Winch Ropes

For more information on selecting the right boat winch rope for your a rib boat, fill in the inquiry form above. Our experts at iRopes are here to help you find the perfect solution for your rib boat navy needs, ensuring you benefit from our high-quality and durable fibre winch ropes.