Have you ever found yourself adrift in a sea of rope options, wondering which one will keep your vessel secure in the face of Mother Nature's fury? You're not alone. In the world of marine equipment, choosing the right weatherproof rope can mean the difference between a smooth sailing adventure and a nautical nightmare.

Welcome to the ultimate guide to weatherproof 1/4 and 5/8 marine rope. Whether you're a seasoned sailor or a weekend warrior, understanding the nuances of these essential tools is crucial for your safety and success on the water. From the lightweight versatility of 1/4 inch lines to the robust strength of 5/8 inch ropes, we'll navigate the vast ocean of options to help you make informed decisions for your maritime needs.

In this comprehensive guide, we'll explore the different materials used in weatherproof ropes, dive into the specific applications of 1/4 and 5/8 inch varieties, and provide you with expert insights on selecting the perfect rope for your vessel. So, batten down the hatches and prepare to embark on a journey that will transform you from a rope novice to a knot-tying connoisseur. Your maritime adventures are about to get a whole lot safer and more efficient!

Understanding Weatherproof Rope Materials

When it comes to marine applications, choosing the right weatherproof rope can make all the difference between smooth sailing and potential disaster. As an experienced sailor, I've learned the hard way that not all ropes are created equal, especially when faced with the harsh conditions of life at sea. Let's dive into the world of synthetic fibers and explore how they've revolutionized the marine rope industry.

Synthetic Fibers for Outdoor Rope

Gone are the days when natural fibers like cotton and hemp ruled the seas. Today's weatherproof ropes are marvels of modern engineering, designed to withstand the toughest conditions Mother Nature can throw at them. Let's take a closer look at the most popular synthetic materials used in marine ropes:

- Polyester: Known for its exceptional UV resistance and durability, polyester is a workhorse in the marine world. I've found it to be particularly reliable for halyards and sheets, where constant exposure to sunlight can quickly degrade lesser materials.

- Nylon: With its impressive strength-to-weight ratio and excellent elasticity, nylon is the go-to choice for anchor lines and mooring ropes. Its ability to absorb shock loads has saved my boat from potential damage more times than I can count.

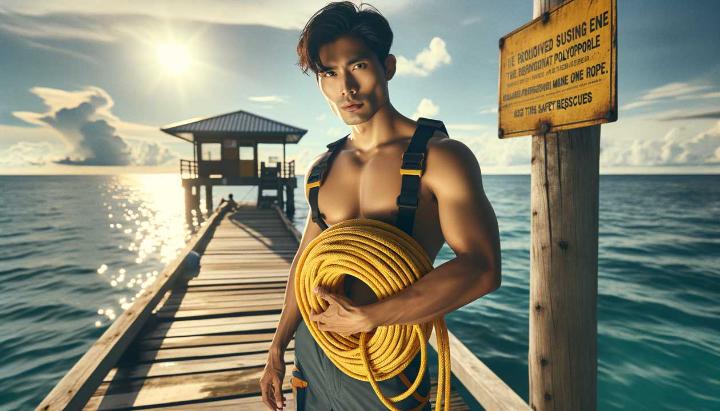

- Polypropylene: Lightweight and buoyant, polypropylene ropes are perfect for water rescue operations and temporary mooring lines. However, be cautious about using them for long-term applications, as they can degrade faster than other synthetics when exposed to UV rays.

- HMPE (High Modulus Polyethylene): This ultra-strong, low-stretch fiber is a game-changer for high-performance sailing. While it comes with a higher price tag, its incredible strength-to-weight ratio makes it worth every penny for competitive sailors.

Natural vs. Synthetic Rope Materials

You might be wondering, "Why bother with synthetic ropes when natural fibers have served sailors for centuries?" It's a fair question, and one I pondered myself when I first started outfitting my boat. After years of experience, I can confidently say that synthetic ropes outperform their natural counterparts in almost every aspect:

Synthetic Rope Advantages

Superior strength, durability, and weather resistance

While natural fibers like manila and sisal have their charm, they simply can't match the performance of synthetic materials when it comes to weatherproofing. Synthetic ropes resist rot, mildew, and UV degradation far better than natural fibers, making them the clear choice for serious mariners.

Have you ever experienced the frustration of a frayed or broken rope in the middle of a crucial maneuver? I certainly have, and it's not an experience I'd wish on anyone. That's why I always recommend investing in high-quality synthetic ropes for any marine application where safety and reliability are paramount.

Remember, the right rope can mean the difference between a smooth voyage and a nautical nightmare. So next time you're outfitting your vessel, take a moment to consider the unique properties of each synthetic material. Your future self (and your boat) will thank you for it.

Common Sizes of 1/4 Inch Marine Rope

As a seasoned sailor, I've come to appreciate the versatility of 1/4 inch marine rope. It's the unsung hero of many a boat, quietly performing essential tasks that keep us safe and our vessels shipshape. Let's dive into the world of these slender yet mighty ropes and explore why they're a staple in any mariner's toolkit.

Types and Materials of 1/4 Inch Marine Rope

When it comes to 1/4 inch marine rope, not all are created equal. The material you choose can make a world of difference in performance and longevity. Here's a quick rundown of the most common types:

- Nylon: This is my go-to for anchor lines. Its elasticity absorbs shock loads, which has saved my hull from a beating more times than I can count.

- Polyester: Perfect for halyards and sheets, polyester stands up to UV rays like a champ. I've had polyester lines outlast my old canvas sails!

- Polypropylene: Lightweight and buoyant, it's great for temporary mooring lines. Just be careful with long-term use - it can degrade in sunlight faster than you'd think.

Choosing the Right 1/4 Inch Marine Rope for Your Boat

Selecting the perfect 1/4 inch rope isn't just about picking a pretty colour (though I won't judge if that's a factor). Here are some key considerations:

- Boat size: For smaller crafts under 20 feet, 1/4 inch rope is often sufficient for most applications.

- Intended use: Are you rigging a halyard or securing a fender? Different tasks demand different properties.

- Environment: Salt water, UV exposure, and temperature all play a role in rope degradation. Choose wisely!

Remember, the strength of your 1/4 inch rope can vary wildly based on material and construction. Always check the breaking strength and err on the side of caution. I once saw a skipper use a line that was too light for mooring - let's just say it was an expensive lesson in rope selection!

Typical lengths for 1/4 inch marine rope range from 50 to 600 feet. I usually keep a variety of lengths on board, from short fender whips to longer anchor lines. It's better to have it and not need it than to need it and not have it, right?

Proper care can extend the life of your 1/4 inch rope significantly. Rinse with fresh water after use in salt water, avoid unnecessary UV exposure, and inspect regularly for wear and tear. Your ropes will thank you, and more importantly, they'll be there for you when you need them most.

So, next time you're outfitting your boat, give some thought to those humble 1/4 inch lines. They may be small, but they're mighty important. Happy sailing, and may your lines always hold fast!

Diving into the Versatility of 5/8 Marine Rope

As a seasoned sailor, I've come to appreciate the remarkable versatility of 5/8 marine rope. It's the unsung hero of many a vessel, quietly performing essential tasks that keep us safe and our boats in shipshape condition. Let's dive into the world of these robust lines and explore why they're a staple in any serious mariner's toolkit.

Types and Materials of 5/8 Marine Rope

When it comes to 5/8 marine rope, the material you choose can make a world of difference in performance and longevity. Here's a quick rundown of the most common types:

- Nylon: My go-to for anchor lines and dock lines. Its elasticity absorbs shock loads, which has saved my hull from a beating more times than I can count.

- Polyester: Perfect for halyards and sheets, polyester stands up to UV rays like a champ. I've had polyester lines outlast my old canvas sails!

- Polypropylene: Lightweight and buoyant, it's great for water rescue operations. Just be careful with long-term use - it can degrade in sunlight faster than you'd think.

One of the key features of 5/8 marine rope is its double braid construction. This design provides added strength, making it suitable for medium-duty applications. For instance, a 5/8 nylon double braid rope can have a breaking strength of up to 15,200 lbs - that's some serious pulling power!

Applications and Uses of 5/8 Marine Rope

The versatility of 5/8 marine rope truly shines when you consider its wide range of applications. Here are some of the most common uses I've encountered in my years on the water:

- Docking: The strength and shock-absorbing properties of 5/8 nylon rope make it ideal for securing your vessel to the dock. If you want to explore more about nylon rope applications, check out Nylon Twisted Rope Strength High Performance in Industry and Marine.

- Anchoring: When you need a reliable anchor line, 5/8 rope provides the perfect balance of strength and manageability. For additional insights on high-strength ropes, see Top Benefits of Using Synthetic Rope for Heavy-duty Tasks.

- Towing: Whether you're towing a dinghy or helping a fellow boater in distress, 5/8 rope is up to the task.

- Rigging: For larger boats, 5/8 rope can be used for various rigging applications, from halyards to sheets. For details on strong synthetic ropes, visit Discover the Strongest Synthetic Ropes for Extreme Applications.

One of the things I love most about 5/8 marine rope is its handling characteristics. It's thick enough to provide a good grip, even with wet hands, but not so bulky that it becomes unwieldy. This makes it a joy to work with, whether you're tying knots or coiling lines for storage.

Remember, the key to getting the most out of your 5/8 marine rope is proper care and maintenance. Rinse it with fresh water after use in salt water, avoid unnecessary UV exposure, and inspect regularly for wear and tear. Your ropes will thank you, and more importantly, they'll be there for you when you need them most.

5/8 Marine Rope: A Boater's Best Friend

Versatile, strong, and reliable for a wide range of marine applications

So, next time you're outfitting your boat, give some serious thought to those trusty 5/8 lines. They might not be the flashiest piece of equipment on board, but they're certainly among the most important. Happy sailing, and may your lines always hold fast!

Key Factors for Selecting the Right Marine Rope

Choosing the perfect marine rope can be a daunting task, especially with the myriad of options available. As a seasoned sailor who's weathered many a storm, I can't stress enough how crucial this decision is. The right rope can mean the difference between a smooth voyage and a nautical nightmare. So, let's dive into the key factors you need to consider when selecting your marine rope.

Material Considerations for Marine Ropes

When it comes to marine ropes, the material is your first line of defense against the harsh elements of the sea. Here's a breakdown of the most popular materials and their unique properties:

- Nylon: The workhorse of marine ropes, nylon is incredibly strong and elastic. It's my go-to choice for anchor lines and dock lines, thanks to its ability to absorb shock loads.

- Polyester: If UV resistance is your top priority, polyester is your best bet. I've found it ideal for halyards and sheets that are constantly exposed to sunlight.

- Polypropylene: Lightweight and buoyant, polypropylene ropes are perfect for water rescue operations. However, they're not the best for long-term use due to their lower UV resistance. If you want to dive deeper into polypropylene rope uses, check out Top Water Sports Uses for Polypropylene Cord.

Strength and Durability Requirements

Understanding the concepts of breaking strength and working load is crucial when selecting your marine rope. The breaking strength is the maximum load a rope can handle before failing, while the working load is typically 20% of the breaking strength for safety reasons.

Here's a quick guide to help you choose the right rope strength based on your boat size:

- Boats up to 20 feet: 3/8" diameter rope with a breaking strength of 3,780 lbs

- Boats 20-30 feet: 1/2" diameter rope with a breaking strength of 6,400 lbs

- Boats 30-40 feet: 5/8" diameter rope with a breaking strength of 9,000 lbs

Remember, these are general guidelines. Always err on the side of caution and consider the specific needs of your vessel and the conditions you'll be sailing in.

Rope Construction Types for Marine Use

The construction of your marine rope plays a significant role in its performance. Here are the main types you'll encounter:

- Braided ropes: These offer excellent strength and are easy to handle. They're my preferred choice for most applications. For more on braided rope benefits, you can explore Top Benefits of Braided Rope for Water and Land Applications.

- Twisted ropes: More traditional and often less expensive, these ropes are good for general-purpose use but can unravel under heavy loads.

- Parallel core ropes: These provide maximum strength and minimal stretch, making them ideal for halyards and sheets on performance sailboats.

When selecting your marine rope, consider the specific application. For example, a braided nylon rope might be perfect for your anchor line, while a parallel core polyester rope could be the best choice for your main halyard.

Pro tip: Always inspect your ropes regularly for signs of wear or damage. A well-maintained rope can last for years, but a damaged one can fail at the worst possible moment.

Remember, choosing the right marine rope is not just about strength or material. It's about finding the perfect balance between durability, handling, and performance for your specific needs. Don't hesitate to consult with experienced sailors or marine supply experts if you're unsure. After all, your safety on the water depends on making the right choice.

Have you had any experiences with different types of marine ropes? I'd love to hear about them in the comments below. Happy sailing, and may your lines always hold fast!

Choosing the right weatherproof rope for marine applications is essential for safety and performance. This guide covers key considerations for 1/4 marine rope and 5/8 marine rope, including materials like polyester for UV resistance, nylon for elasticity, polypropylene for buoyancy, and HMPE for ultra-strength. Understanding the different sizes assists in selecting the right rope for varied applications such as flag halyards, docking, and anchoring. Additionally, evaluating factors such as intended use, environmental conditions, and rope construction can ensure your ropes meet all performance requirements.

Get in Touch for Custom Rope Solutions

For tailored advice on selecting the best marine rope for your needs, please fill out the form above. Our experts are here to assist with custom solutions for all your marine rope requirements.