Have you ever wondered what keeps a climber suspended hundreds of metres above the ground or secures a massive ship to its mooring? The answer lies in a remarkable material that's revolutionised the rope industry: nylon. In the world of super strong rope, nylon reigns supreme, offering unparalleled performance across a spectrum of applications.

Imagine a material so versatile it can withstand the harsh conditions of the open sea, the rigorous demands of industrial construction, and the life-or-death scenarios faced by rock climbers. That's the power of strong nylon rope. But what makes this strong rope material so exceptional?

At iRopes, we've dedicated ourselves to harnessing the full potential of nylon in our rope manufacturing process. From active ropes that support thrill-seekers to mooring ropes that safeguard vessels, and power ropes that drive industry forward, nylon's excellent performance sets a new standard in rope technology.

Join us as we unravel the secrets behind nylon's strength, exploring its unique properties, manufacturing techniques, and the myriad ways it's transforming industries around the globe. Whether you're a wholesale customer seeking cutting-edge rope solutions or simply curious about the science behind super strong materials, this deep dive into the world of nylon ropes promises to be an eye-opening journey.

Advantages of Nylon as a Strong Rope Material

When it comes to choosing a rope for your next adventure or industrial application, nylon stands out as a true champion. As an avid climber and outdoor enthusiast, I've had my fair share of experiences with various rope materials, but nylon consistently impresses me with its remarkable qualities. Let's dive into what makes nylon such a stellar choice for strong ropes.

Strength and Durability of Nylon Rope

Nylon rope is a force to be reckoned with. Its impressive tensile strength outshines many other common rope materials, making it the go-to choice for applications where reliability is non-negotiable. I remember a particularly challenging rock climbing expedition where our nylon rope held firm against sharp edges and heavy loads, instilling a sense of confidence that's hard to put into words.

- Superior strength-to-weight ratio: Nylon ropes offer exceptional strength without the bulk, allowing for easier handling and transport.

- Remarkable durability: These ropes stand up to wear and tear, maintaining their integrity even in harsh conditions.

- Resistance to environmental factors: Nylon's resilience against UV rays, chemicals, and abrasion ensures longevity in diverse settings.

Shock Absorption and Elasticity Benefits

One of the standout features of nylon rope is its incredible elasticity and shock absorption capabilities. This characteristic is particularly crucial in dynamic activities like rock climbing or in industrial applications where sudden load changes are common.

The elasticity of nylon rope can absorb up to 2.5 times more energy than polyester rope of the same size, making it ideal for fall protection and dynamic loads.

This ability to stretch and return to its original length not only enhances safety but also extends the rope's lifespan. Have you ever wondered why nylon is the preferred choice for climbing ropes? It's this very quality that makes it so dependable in life-or-death situations.

Versatility and Applications of Nylon Rope

The adaptability of nylon rope is truly remarkable. Its unique combination of strength, elasticity, and durability makes it suitable for a wide range of applications across various industries.

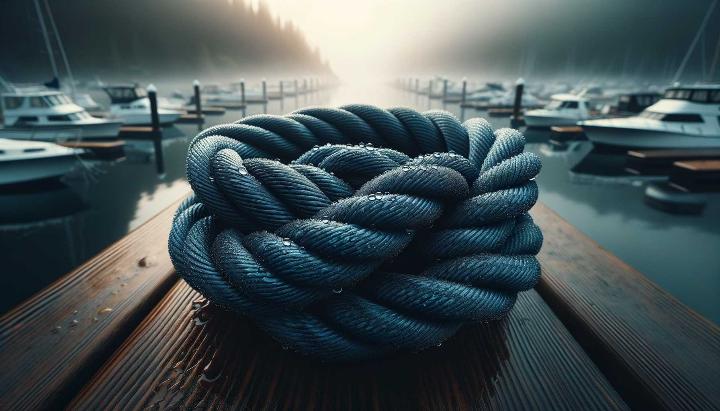

- Marine and boating: Nylon's resistance to saltwater and excellent shock absorption make it perfect for mooring and anchor lines.

- Sports and outdoor activities: From rock climbing to camping, nylon ropes are a staple in outdoor gear.

- Industrial and construction: The strength and durability of nylon make it ideal for heavy-duty applications like towing and lifting.

In my experience, whether I'm setting up a campsite in the backcountry or helping a friend secure their boat at the marina, nylon rope has never let me down. Its versatility is truly unmatched, adapting to various scenarios with ease.

As we explore the world of strong rope materials, it's clear that nylon stands out for its exceptional combination of strength, elasticity, and versatility. Whether you're an outdoor enthusiast, a marine professional, or working in industrial applications, nylon rope offers the reliability and performance you need. Have you considered how nylon rope could enhance your next project or adventure?

For those who are interested in comparing different materials and understanding the applications of various rope types, you may find the insights in our Essential Guide to Brown Polypropylene and Nylon Ropes insightful. This guide provides a valuable look into different materials and their specific benefits.

Understanding the Properties of Super Strong Rope Made from Nylon

As a rope enthusiast and avid climber, I've always been fascinated by the incredible strength and versatility of nylon ropes. Let's dive into the science behind these remarkable fibres and explore what makes nylon such a popular choice for super strong ropes.

Molecular Structure of Nylon Fibres

At the heart of nylon's impressive strength lies its unique molecular structure. Nylon is a synthetic polymer, composed of long chains of repeating units called monomers. These chains are held together by strong hydrogen bonds, giving nylon its exceptional tensile strength and durability.

Imagine these molecular chains as a series of interlocking links in a chain. When force is applied, these links stretch and align, distributing the load evenly across the entire structure. This molecular alignment is what gives nylon its remarkable ability to withstand heavy loads without breaking.

Manufacturing Process of Strong Nylon Rope

The journey from raw nylon to super strong rope is a fascinating process that combines cutting-edge technology with time-honoured rope-making techniques. Here's a simplified breakdown of how nylon rope is made:

- Extrusion: Nylon pellets are melted and forced through tiny holes to create long, continuous filaments.

- Drawing: These filaments are stretched to align the molecules, increasing strength and reducing diameter.

- Twisting: Multiple filaments are twisted together to form yarns.

- Braiding or twisting: Yarns are then braided or twisted together to create the final rope structure.

If you're keen to understand more about the specific use cases and how nylon compares to other synthetic materials, consider exploring our Understanding Plastic and Nylon Rope Manufacturing Process.

Different Types of Nylon Used in Rope-Making

Not all nylon ropes are created equal. There are several types of nylon used in rope manufacturing, each with its own unique properties:

- Nylon 6: Known for its high tensile strength and excellent abrasion resistance.

- Nylon 6,6: Offers superior strength and heat resistance compared to Nylon 6.

- Nylon 4,6: Provides exceptional strength and stiffness, ideal for high-performance applications.

The choice of nylon type depends on the specific requirements of the rope's intended use. For instance, in my rock climbing adventures, I've found that ropes made from Nylon 6,6 offer the perfect balance of strength and elasticity for dynamic falls.

Factors Influencing the Strength of Nylon Ropes

Several factors contribute to the overall strength of a nylon rope:

- Diameter: Generally, thicker ropes are stronger, but there's a trade-off with weight and flexibility.

- Construction method: Braided ropes often offer better strength-to-weight ratios than twisted ropes.

- Environmental conditions: Exposure to UV light, chemicals, and moisture can affect rope strength over time.

- Usage history: Repeated loading and unloading can impact a rope's long-term strength.

Understanding these factors is crucial when selecting the right nylon rope for your specific needs. Whether you're securing a yacht in choppy waters or trusting your life to a climbing rope, knowing the properties of your super strong nylon rope can make all the difference.

Have you ever wondered how nylon ropes compare to other synthetic materials like polyester or Dyneema? For a deeper dive into the nuances, you might find our comparison helpful: Nylon vs Polyester: Which Kinetic Recovery Rope is Best?

Applications and Benefits of Strong Nylon Rope

As a seasoned sailor and outdoor enthusiast, I've had the pleasure of working with various rope materials throughout my adventures. However, time and time again, I find myself reaching for strong nylon rope. Its versatility and exceptional performance across diverse applications never fail to impress. Let's dive into the myriad ways nylon rope proves its worth in different industries and explore why it's become the go-to choice for so many professionals and hobbyists alike.

Versatile Uses of Nylon Rope in Various Industries

The adaptability of nylon rope is truly remarkable, making it a staple in numerous sectors:

- Marine applications: From mooring lines to anchor rodes, nylon's strength and shock-absorbing properties make it ideal for withstanding the constant motion of waves and tides.

- Construction and industrial use: Its high tensile strength makes it perfect for heavy lifting, towing, and securing cargo in warehouses and construction sites.

- Sports and outdoor activities: Rock climbing, camping, and even recreational boating all benefit from nylon's durability and flexibility.

I recall a particularly choppy day out on the harbour when our nylon mooring lines were put to the test. Despite the relentless battering from waves, the ropes held firm, showcasing their incredible resilience in marine environments.

Key Advantages of Nylon Rope for Dynamic Load Applications

What sets nylon apart in scenarios involving sudden or fluctuating loads? Let's break it down:

- Superior shock absorption: Nylon's ability to stretch and recover helps dissipate energy from sudden impacts, reducing the risk of snapback and equipment damage.

- Excellent elasticity: This characteristic allows nylon to handle dynamic loads more effectively than stiffer materials, making it ideal for applications with varying tension.

- Wet strength retention: Unlike some materials that weaken when wet, nylon maintains 85-90% of its strength in damp conditions, a crucial feature for marine and outdoor use.

Comparing Nylon Rope to Other Synthetic Materials

While nylon excels in many areas, it's important to understand how it stacks up against other synthetic ropes:

- Nylon vs. Polyester: Nylon offers superior shock absorption and elasticity, making it better for dynamic loads. Polyester, however, has lower stretch and better UV resistance.

- Nylon vs. Polypropylene: Nylon is stronger and more durable but also more expensive. Polypropylene floats, making it useful for water rescue scenarios.

- Nylon vs. High-Performance Fibres (e.g., Dyneema): While high-performance fibres offer incredible strength-to-weight ratios, nylon remains more cost-effective and better at handling shock loads.

Having used various rope types in my sailing career, I've found that understanding these differences is crucial for selecting the right rope for each specific application.

As we've explored, strong nylon rope offers a unique combination of strength, versatility, and dynamic load handling that makes it indispensable across numerous industries. Whether you're securing a vessel in rough seas, setting up a construction pulley system, or preparing for your next outdoor adventure, nylon rope proves time and again to be a reliable choice. Have you considered how incorporating nylon rope into your projects could enhance safety and efficiency?

Essential Techniques for Maintaining Strong Rope Material

As an avid climber and sailing enthusiast, I've learned that the longevity and reliability of your rope are just as crucial as its initial strength. Proper maintenance of strong rope material, particularly nylon, can significantly extend its lifespan and ensure your safety in critical situations. Let's dive into some essential techniques that will keep your ropes in top-notch condition.

Proper Cleaning and Storage Methods

Keeping your ropes clean and storing them correctly is vital for maintaining their integrity. Here's how I care for my ropes after a day out on the cliffs or the sea:

- Gentle cleaning: Rinse your rope with fresh water to remove salt, dirt, and debris. For stubborn grime, use a mild soap specifically designed for ropes.

- Thorough drying: Always air dry your rope in a shaded, well-ventilated area. Direct sunlight can weaken the fibres over time.

- Proper coiling: Use the butterfly coil method to prevent kinks and twists that can compromise the rope's strength.

- Ideal storage: Keep your rope in a cool, dry place away from sunlight, chemicals, and sharp objects. A dedicated rope bag can provide extra protection.

Regular Inspection and Damage Prevention

Regular inspections are crucial for catching potential issues before they become dangerous. Here's what I look for when examining my ropes:

- Visual checks: Look for fraying, discoloration, or flat spots along the rope's length.

- Tactile inspection: Run the rope through your hands, feeling for any inconsistencies or lumps in the core.

- End-to-end examination: Pay special attention to the rope ends, where wear is often most pronounced.

- Documentation: Keep a log of your rope's usage and inspection history to track its lifespan.

Remember, prevention is always better than cure. Avoid stepping on your rope, dragging it over rough surfaces, or exposing it to harsh chemicals. These simple precautions can significantly extend your rope's life.

Did you know? A well-maintained nylon rope can last up to 10 years with proper care, while neglected ropes may need replacement in as little as 1-2 years.

By following these maintenance techniques, you're not just prolonging the life of your rope; you're ensuring your safety and the safety of those who depend on it. Whether you're scaling a cliff face or securing a vessel, a well-maintained rope is your lifeline. How often do you inspect and clean your ropes? It might be time to establish a regular maintenance routine if you haven't already.

Remember, when it comes to strong rope material like nylon, a little care goes a long way. Your future self will thank you for the extra effort you put in today to maintain your ropes. Happy climbing, sailing, or whatever adventure your ropes take you on!

Nylon’s prominence as a super strong rope stems from its impressive molecular structure and manufacturing process, making it an ideal go-to choice for diverse applications. Among the various types of strong rope material, nylon excels in tensile strength, durability, and elasticity, enabling its use across active, mooring, and power ropes. Its resistance to environmental factors and ability to retain strength when wet ensures versatility from marine to industrial settings. For maintaining a strong nylon rope, proper storage, regular inspections, and attentive cleaning can significantly extend its lifespan and reliability, enhancing safety and performance in critical applications.

Discover Tailor-Made Solutions for Your Rope Needs

Located above, the form is your gateway to tailor-made rope solutions that fit your specific requirements. At iRopes, we promise not only durability and flexibility with our nylon ropes but a commitment to support your ventures, be they marine, industrial, or outdoors. Fill out the form to learn more about how our custom solutions can meet your needs and elevate your projects to new heights.