Imagine you're about to embark on a crucial project, and the success hinges on one decision: steel rope fittings or synthetic rope? It's a choice that can make or break your operation, yet many overlook the critical differences between these two options. At iRopes, we've seen firsthand how this decision impacts everything from off-road adventures to industrial applications.

In the world of rope manufacturing, the battle between steel and synthetic isn't just about strength – it's a complex dance of flexibility, weight, and corrosion resistance. As leaders in customised rope solutions, we've witnessed the pros and cons of both materials across diverse industries. Whether you're rigging for a yacht race or securing heavy machinery, understanding these key differences is essential.

In this post, we'll dive deep into the strengths and weaknesses of wire rope fittings and synthetic alternatives. We'll explore how flexibility can make or break your project, why weight matters more than you might think, and the surprising truth about corrosion resistance. By the end, you'll have the insider knowledge to make an informed decision that could save you time, money, and headaches down the line.

Ready to unravel the mystery of steel vs synthetic? Let's dive in and discover which rope reigns supreme for your unique needs.

Wire Rope vs Synthetic Rope: Flexibility Comparison

When it comes to choosing the right rope for your project, flexibility is a crucial factor to consider. As someone who's worked with both wire rope fittings and synthetic ropes for years, I can tell you that the difference in flexibility between these two options is like night and day.

Limited Flexibility of Wire Rope Fittings

Wire rope fittings, while incredibly strong, are notoriously rigid. This lack of flexibility can be both a blessing and a curse, depending on your application. I remember a time when I was working on a heavy-duty crane project, and the wire rope's stiffness made it challenging to route around tight corners. However, that same rigidity provided excellent stability for the heavy loads we were lifting.

- Composition affects flexibility: Wire ropes are made of multiple metal strands twisted together, which inherently limits their flexibility.

- Wire count matters: The number of individual wires in a rope can impact its flexibility. More wires generally mean more flexibility, but at the cost of increased manufacturing complexity.

- Fiber core option: Some wire ropes come with a fiber core, offering slightly more flexibility but less crush resistance.

Enhanced Flexibility of Synthetic Rope

On the flip side, synthetic ropes are a game-changer when it comes to flexibility. I've used them in various scenarios, from marine applications to off-road vehicle recovery, and their pliability never ceases to amaze me.

The enhanced flexibility of synthetic ropes offers several advantages:

- Easier handling: Synthetic ropes are significantly lighter and more pliable, making them easier to manipulate and store.

- Versatile applications: Their flexibility allows for use in a wider range of scenarios, especially where bending and wrapping are required.

- On-site repairs: Unlike wire ropes, many synthetic ropes can be spliced or repaired in the field, thanks to their flexible nature.

Have you ever tried to coil a wire rope and a synthetic rope of the same diameter? The difference is striking. While the wire rope maintains its shape stubbornly, the synthetic rope flows like water through your hands.

When choosing between wire rope fittings and synthetic rope, consider your specific needs. If you require high flexibility, synthetic rope is likely your best bet. However, for applications where rigidity and strength are paramount, wire rope fittings still have their place.

Remember, the right choice depends on your unique requirements. What's your experience with wire and synthetic ropes? Have you found flexibility to be a deciding factor in your projects?

Synthetic Rope vs Wire Cable: Weight Advantages

As someone who's spent years working with both synthetic and wire ropes, I can tell you that the weight difference between these two options is truly eye-opening. Let me share a personal anecdote that illustrates this point perfectly.

Last summer, I was helping a mate outfit his new off-road rig. We were comparing winch options, and I suggested we physically handle both types of rope to feel the difference. The moment he lifted the synthetic winch rope, his eyes widened in disbelief. "Crikey," he exclaimed, "it's like comparing a feather to a brick!"

Performance Benefits of Lightweight Synthetic Rope

The lightweight nature of synthetic rope offers several advantages that can significantly impact your off-roading or work experience:

- Effortless handling: Synthetic rope is about 8 times lighter than steel cable, making it a breeze to spool, unspool, and manoeuvre in tight spots.

- Reduced vehicle strain: By choosing synthetic rope, you can shave off a good 10-15kg from your vehicle's front end. This weight reduction can improve fuel efficiency and overall vehicle performance.

- Enhanced winch performance: The lighter weight allows for faster line speed and less motor strain, potentially extending the life of your winch.

Want to learn more about the benefits of synthetic winch ropes? Check out our detailed guide on High-Strength Winch Line Rope Upgrades.

Considerations When Choosing Synthetic Winch Rope

While the weight advantages of synthetic rope are clear, it's important to consider a few factors before making your choice:

- Breaking strength: Despite being lighter, high-quality synthetic ropes often match or exceed the breaking strength of steel cables of the same diameter.

- Environmental factors: Synthetic ropes can be more susceptible to UV damage and abrasion. Proper care and occasional replacement may be necessary for optimal performance.

- Heat sensitivity: Unlike steel cables, synthetic ropes can be damaged by extreme heat generated during winching operations. Using a heat sleeve or allowing cool-down periods is essential.

Want to delve deeper into synthetic winch ropes and their use in off-road scenarios? Check out our article on Synthetic Winch Rope for Off-Road Use.

Have you ever used both types of winch lines? What was your experience with the weight difference, and how did it affect your off-roading or work efficiency? I'd love to hear your thoughts and experiences in the comments below!

Remember, while the lightweight nature of synthetic rope offers numerous benefits, the best choice ultimately depends on your specific needs and usage conditions. Always consider factors like durability, maintenance requirements, and your typical operating environment when making your decision.

Corrosion Resistance: Steel vs Synthetic Rope

As someone who's spent years working with various rope materials in harsh environments, I can tell you that corrosion resistance is a critical factor to consider when choosing between steel and synthetic rope fittings. Let's dive into the nitty-gritty of how these two materials stack up against the relentless forces of nature.

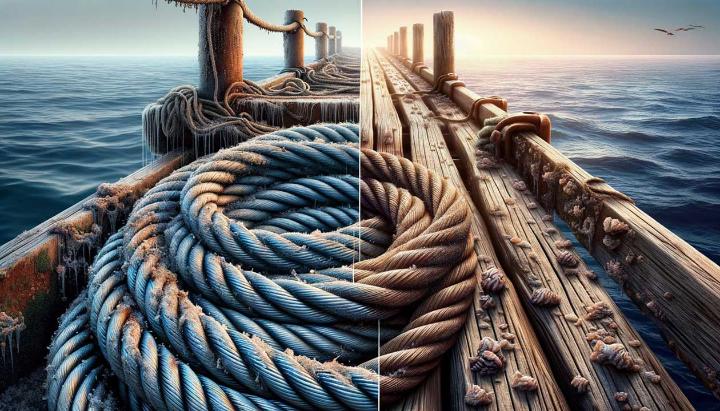

Steel Rope Fittings and Corrosion Susceptibility

Steel rope fittings, while incredibly strong, have an Achilles' heel: corrosion. I've seen firsthand how quickly a seemingly robust steel cable can deteriorate when exposed to the elements. Here's what you need to know:

- Moisture is the enemy: Steel rope fittings are particularly vulnerable to rust when exposed to moisture, especially in marine environments.

- Chemical reactions: Certain chemicals can accelerate corrosion, weakening the steel's integrity over time.

- Protective measures: Galvanization and regular lubrication can help, but they're not foolproof solutions.

I remember a project where we used standard steel wire rope for a coastal installation. Within months, we noticed rust forming, and the rope's strength was compromised. It was a costly lesson that led us to explore more corrosion-resistant options.

Advantages of Synthetic Rope in Corrosive Environments

Synthetic ropes have been a game-changer in corrosive environments. Their resistance to corrosion is one of the main reasons I often recommend them for challenging applications. Here's why:

- Inherent corrosion resistance: Materials like polyester and nylon don't rust or corrode like steel.

- Longevity in harsh conditions: Synthetic ropes maintain their strength and integrity even when exposed to saltwater or chemicals.

- Reduced maintenance: They require less frequent inspections and replacements compared to steel ropes in corrosive environments.

However, it's not all smooth sailing with synthetic ropes. They have their own limitations:

- UV sensitivity: Prolonged exposure to sunlight can degrade some synthetic materials.

- Abrasion concerns: Synthetic ropes may wear faster than steel when subjected to rough surfaces.

For further insights into the strength and benefits of synthetic ropes in various conditions, read our article on High-Strength Synthetic Winch Rope.

In my experience, the corrosion resistance of synthetic ropes often outweighs these drawbacks in many applications. For instance, we switched to synthetic ropes for our marine winches, and the difference in durability and performance was night and day.

Pro Tip: When using synthetic ropes in corrosive environments, always inspect for signs of UV damage or abrasion. A little vigilance goes a long way in ensuring safety and longevity.

Remember, the choice between steel and synthetic rope fittings isn't always black and white. It depends on your specific application, environment, and maintenance capabilities. Have you had any experiences with corrosion affecting your rope choices? I'd love to hear your stories and insights in the comments below!

Understanding the differences between steel wire rope fittings and synthetic rope is crucial for making informed decisions. Steel wire fittings are strong but less flexible, making them difficult to handle in some applications. They are also prone to corrosion, especially in moist or chemical environments. On the other hand, synthetic rope fittings are lighter and easier to manage, with enhanced flexibility and corrosion resistance, which makes them ideal for various uses that require high flexibility and longevity.

Have Specific Rope Needs? Contact Us Today!

Fill out the inquiry form above to learn more about our wire rope fittings and synthetic rope solutions. Our team at iRopes is ready to assist you with customised solutions tailored to your unique requirements.