When it comes to lifting and rigging, the age-old debate of steel wire rope versus fibre rope continues to spark controversy among industry professionals. But what if I told you that the real game-changer lies in the accessories that accompany these ropes? As a leading manufacturer of high-quality ropes and accessories, we've seen firsthand how the right choice can make or break a project.

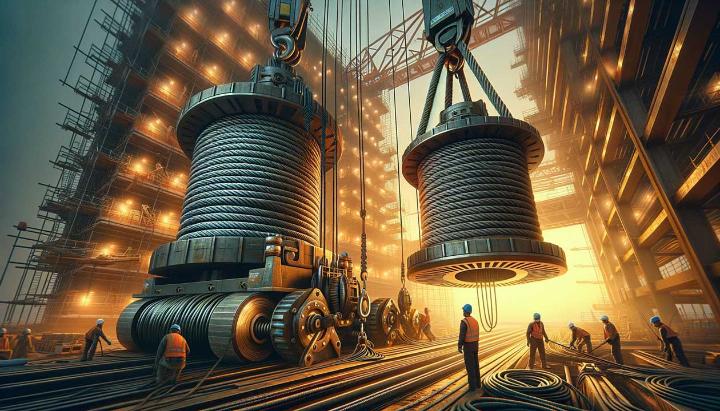

Picture this: a construction site where a single miscalculation in rigging could result in catastrophic failure. It's scenarios like these that underscore the critical importance of understanding the nuances between steel cable accessories and rope accessories. In this comprehensive comparison, we'll delve into the strengths, weaknesses, and ideal applications of both, empowering you to make informed decisions that enhance safety, efficiency, and performance in your lifting operations.

Whether you're overseeing heavy-duty industrial projects or seeking versatile solutions for outdoor adventures, this guide will equip you with the knowledge to choose the perfect accessories for your specific needs. Join us as we unravel the complexities of steel cable and rope accessories, and discover how the right choice can elevate your rigging game to new heights.

Comparing Wire Rope Accessories and Rope Accessories

When it comes to lifting and rigging applications, choosing the right accessories can make all the difference in safety and efficiency. Let's dive into the world of wire rope and fiber rope accessories, exploring their unique characteristics and applications.

Types of Wire Rope Fittings and Their Applications

Wire rope accessories are the unsung heroes of heavy-duty lifting operations. As someone who's spent years in the rigging industry, I've seen firsthand how these robust fittings can make or break a project. Here are some common types:

- Wire rope clips: These versatile fittings come in two main types - U-bolt and double saddle. They're essential for creating eyes or loops at the end of wire ropes.

- Thimbles: These heart-shaped fittings protect the rope from wear and tear, especially when it's looped around a hook or shackle.

- Sockets: Ideal for permanent end terminations, sockets provide a strong and secure connection point for wire ropes.

Advantages of Wire Rope vs. Fiber Rope Accessories

Now, let's compare wire rope accessories to their fiber rope counterparts:

- Strength-to-weight ratio: Wire rope accessories generally offer superior strength for their size, making them ideal for heavy lifting.

- Durability: These fittings are built to withstand harsh conditions, resisting abrasion and corrosion better than most fiber rope accessories.

- Cost considerations: While initially more expensive, wire rope accessories often prove more cost-effective in the long run due to their longevity.

On the flip side, fiber rope accessories shine in different ways:

- Lightweight and flexible: Perfect for applications where weight is a concern or frequent adjustments are needed.

- User-friendly: Fiber rope accessories are often easier to handle and install, reducing setup time.

- Versatility: They adapt well to various configurations and are ideal for temporary setups.

Remember, the choice between wire rope and fiber rope accessories often comes down to your specific application. Always consult with a rigging expert to ensure you're using the right tools for the job.

In my experience, industries like construction and shipping often prefer wire rope accessories for their heavy-duty capabilities. However, I've seen outdoor adventure companies and theatrical rigging teams swear by fiber rope accessories for their ease of use and adaptability.

What's your take on this? Have you had any memorable experiences with either type of accessory in your work? Understanding the pros and cons of each can help you make informed decisions for your next project, ensuring both safety and efficiency.

Strength and Durability of Steel Cable Accessories

When it comes to heavy-duty lifting and rigging operations, the strength and durability of steel cable accessories are unparalleled. As someone who's spent years in the field, I've seen firsthand how these robust components can make or break a project. Let's dive into what makes steel cable accessories the go-to choice for demanding applications.

Types of Steel Cables and Their Properties

Not all steel cables are created equal. The type you choose can significantly impact your project's success. Here's a quick rundown of common steel cable types and their unique properties:

- Stainless steel cables: Corrosion-resistant and ideal for marine environments or food processing industries.

- Galvanized steel cables: Zinc-coated for added protection against rust and wear.

- High-tensile steel wire: Offers the highest strength-to-weight ratio, perfect for heavy lifting operations.

Each type has its strengths, but they all share one common trait: exceptional durability. I've seen stainless steel cables withstand harsh saltwater environments for years without a hint of corrosion. It's truly impressive stuff.

Breaking Strength and Working Load Limits

Understanding breaking strength and working load limits is crucial for safe and effective use of steel cable accessories. Let's break it down:

- Breaking strength: The maximum load a cable can withstand before failing. For example, a common 5/16 inch steel cable can have a minimum breaking strength of up to 10,000 pounds.

- Working load limit (WLL): The maximum load a cable should carry in normal operations. It's typically 20% of the breaking strength. For our 5/16 inch cable, the WLL would be around 2,000 pounds.

Always err on the side of caution. I once witnessed a near-miss when a team pushed a cable beyond its WLL. Trust me, it's not worth the risk.

Remember, always factor in a safety margin when calculating loads. Your WLL should be at least five times less than the cable's breaking strength.

Steel cable accessories shine in their resistance to abrasion, corrosion, and harsh environmental factors. I've seen them perform flawlessly in scorching deserts and frigid arctic conditions alike. Their versatility makes them suitable for a wide range of heavy-duty applications and extreme environments.

Have you ever used steel cable accessories in challenging conditions? I'd love to hear about your experiences. Understanding the strengths and limitations of these robust tools is key to ensuring safety and efficiency in any rigging operation.

Versatility and Flexibility of Rope Accessories

When it comes to rigging and lifting applications, the versatility and flexibility of rope accessories can't be overstated. As someone who's worked with various rope systems for years, I can attest to the incredible adaptability these accessories offer. Let's dive into what makes rope accessories so versatile and how they can benefit your projects.

Types of Flexible Rope Accessories

Rope accessories come in various forms, each designed to enhance the rope's flexibility and utility. Here are some of the most common types I've encountered in my work:

- Rope clips: These versatile fittings allow for quick adjustments and secure connections, perfect for temporary setups.

- Thimbles: Used to protect the rope from wear and tear, especially at attachment points, enhancing both flexibility and durability.

- Hooks: Available in various designs, hooks provide easy attachment options for different applications.

- Swivels: These prevent twisting and tangling, maintaining the rope's flexibility during use.

The beauty of these accessories lies in their ability to work with different rope materials. Whether you're using nylon, polypropylene, or high-performance synthetic fibres, there's a flexible accessory to suit your needs.

Applications and Benefits of Versatile Rope Products

The versatility of rope accessories makes them indispensable across various industries. In my experience, I've seen them shine in:

- Marine applications: From mooring lines to sail rigging, flexible rope accessories adapt to the ever-changing demands of maritime environments.

- Construction: Lightweight and easy to handle, these accessories are perfect for temporary rigging and safety lines on construction sites.

- Adventure sports: Rock climbing and zip-lining rely heavily on versatile rope accessories for both safety and performance.

- Theatre and event production: The ability to quickly adjust and reconfigure makes these accessories invaluable for stage rigging and set design.

One of the biggest benefits I've noticed is how these versatile accessories can significantly reduce setup time. For instance, on a recent outdoor event, we were able to adjust our rigging on the fly using quick-release clips, saving hours of work.

Pro tip: When choosing rope accessories, consider not just the immediate application but potential future uses. The more versatile your accessories, the more value you'll get from your investment.

The adaptability of rope accessories to various attachment points and configurations is another key advantage. Whether you're working with natural anchors in an outdoor setting or engineered attachment points in a warehouse, there's likely a rope accessory that can make the connection safe and secure.

Have you ever found yourself in a situation where the versatility of rope accessories saved the day? I'd love to hear your experiences. Understanding the full potential of these flexible tools can open up new possibilities in your rigging and lifting projects, ensuring you're always prepared for whatever challenges come your way.

Key Factors for Choosing Between Wire Rope and Rope Accessories

As someone who's spent years in the rigging industry, I've learned that selecting the right accessories for your lifting and pulling applications can make or break a project. Let's dive into the crucial factors you need to consider when choosing between wire rope and rope accessories.

Understanding Wire Rope Properties and Applications

Wire rope accessories are the workhorses of heavy-duty lifting operations. Their unique construction offers several advantages:

- Strength-to-weight ratio: Wire rope typically offers superior strength for its size, making it ideal for heavy lifting tasks.

- Durability: These accessories are built to withstand harsh conditions, resisting abrasion and corrosion better than most standard rope accessories.

- Flexibility: Despite their strength, wire ropes can be surprisingly flexible, allowing for various configurations in complex rigging setups.

I've seen wire rope accessories excel in industries like construction, shipping, and offshore oil rigs. For instance, on a recent construction project, we used wire rope slings to lift massive steel beams with precision and safety that would have been challenging with standard rope.

Essential Rope Accessory Considerations for Various Uses

On the flip side, standard rope accessories have their own set of advantages:

- Lightweight and easy to handle: Perfect for applications where weight is a concern or frequent adjustments are needed.

- Versatility: They adapt well to various configurations and are ideal for temporary setups.

- Cost-effectiveness: Often more affordable for lighter-duty applications.

In my experience, industries like outdoor recreation, theatrical rigging, and small-scale construction often prefer standard rope accessories for their ease of use and adaptability.

Pro tip: Always consider the specific requirements of your project. The right choice between wire rope and standard rope accessories can significantly impact safety, efficiency, and overall project success.

When making your decision, consider these key factors:

- Load capacity: Assess the weight and type of loads you'll be handling. Wire rope generally excels with heavier loads.

- Environmental conditions: Will your accessories be exposed to harsh elements? Wire rope often performs better in extreme conditions.

- Frequency of use and adjustments: If you need to make frequent changes to your rigging setup, standard rope accessories might offer more convenience.

- Safety requirements: Always prioritize safety. Ensure the accessories you choose meet or exceed the safety standards for your specific application.

Remember, there's no one-size-fits-all solution. I've seen projects where a combination of wire rope and standard rope accessories provided the best results. The key is understanding the strengths and limitations of each type and making an informed decision based on your specific needs.

Have you faced any challenges in choosing between wire rope and standard rope accessories for your projects? I'd love to hear about your experiences and how you tackled the decision-making process. Share your thoughts in the comments below!

For additional insights, you might find our article on Steel Cable Rope vs. Fiber Rope: Strength and Safety helpful.

Choosing between steel cable accessories and rope accessories is crucial for lifting and rigging applications, as each has unique advantages. Steel cable accessories offer higher breaking strength, durability, and resistance to harsh conditions, making them ideal for heavy-duty tasks. Meanwhile, rope accessories are lightweight, flexible, and adaptable, suiting applications requiring frequent adjustments. Factors such as load capacity, environmental conditions, and cost must guide your choice. Understanding the strengths and nuances of both can significantly enhance the efficiency and safety of your projects.

Get Expert Advice on Choosing the Right Accessories

Need customised advice on rope accessories, wire rope accessories or steel cable accessories? Fill in the form above to connect with our specialists for tailored solutions and guidance.