Imagine standing on the brink of a critical project and pondering whether to choose a nylon coated steel cable or a double braided nylon rope. The decision is far from trivial – the right choice can make or break the success and safety of your operations. Whether you’re tackling heavy-duty industrial tasks or engaging in adventurous outdoor activities, understanding the strengths and applications of these options is essential.

Nylon coated steel cables are engineered for unparalleled strength and resilience, making them ideal for demanding environments and heavy loads. Conversely, double braided nylon ropes offer exceptional flexibility and shock absorption, perfect for applications where ease of handling and resilience to impact are key.

In this post, we’ll delve into the distinct advantages each of these materials holds, the scenarios where they excel, and provide a comprehensive comparison to help you determine the perfect fit for your needs. Stay with us as we explore the intricate details and practical applications of these essential tools, so you can make an informed and confident decision.

Advantages of Nylon Coated Steel Cable

When it comes to heavy-duty applications that demand durability and resilience, nylon coated steel cables rise above the rest. Imagine a scenario where you need a cable that can withstand the toughest environments without compromising on strength or longevity. That's where nylon coated steel cables shine.

Benefits of Nylon Coating Over Steel Cables

- Enhanced abrasion resistance - The nylon coating acts as a protective layer, shielding the steel core from wear and tear caused by friction, ensuring a longer service life.

- Improved UV protection - Unlike bare steel cables, the nylon coating safeguards the cable from the damaging effects of ultraviolet radiation, preventing premature degradation and extending its lifespan.

- Resistance to harsh environments - Whether it's acidic conditions, exposure to chemicals, or extreme temperatures, nylon coated steel cables are built to withstand the harshest environments without losing their integrity.

- Flexibility and low-friction properties - The nylon coating provides a smooth surface, reducing friction and allowing for easier handling and manipulation of the cable, even in tight spaces.

Applications and Uses of Nylon Coated Steel Cables

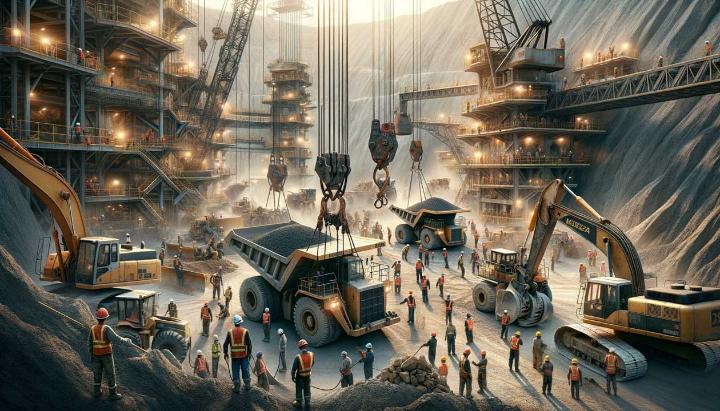

The versatility of nylon coated steel cables makes them the go-to choice for a wide range of industries and applications. From heavy-duty construction sites to rugged outdoor environments, these cables are engineered to perform:

- Industrial machinery and equipment - Nylon coated steel cables are a reliable solution for heavy lifting, rigging, and load-bearing applications in factories, warehouses, and construction sites.

- Marine and offshore operations - The corrosion-resistant properties of nylon coated cables make them ideal for use in harsh marine environments, ensuring safe and efficient operations.

- Outdoor rigging and adventure sports - For activities like rock climbing, zip-lining, and high-ropes courses, nylon coated steel cables provide the perfect balance of strength and flexibility.

- Mining and extraction industries - The durability and abrasion resistance of these cables make them well-suited for the demanding environments found in mining, oil, and gas operations.

Whether you're working on a construction site, rigging equipment for outdoor adventures, or operating in harsh industrial environments, nylon coated steel cables offer unparalleled durability and performance. Their unique combination of strength, abrasion resistance, and weather protection make them a reliable choice for demanding applications where safety and longevity are paramount.

Advantages of Double Braided Nylon Rope

When it comes to versatility and performance, double braided nylon ropes are a true powerhouse. Imagine a rope that combines lightweight flexibility with exceptional strength and durability – that's the beauty of this innovative construction. At the core of these ropes lies a tightly braided nylon core, encased within a braided nylon jacket or sleeve. This double braid design is what sets these ropes apart, making them a favorite among outdoor enthusiasts, marine professionals, and anyone who demands the best from their gear.

High Strength and Flexibility

One of the most remarkable aspects of double braided nylon ropes is their ability to offer high strength without sacrificing flexibility. The nylon fibers used in their construction boast impressive tensile strength, allowing these ropes to withstand substantial loads and stress. At the same time, the braided construction ensures a level of flexibility that makes handling, coiling, and knot-tying a breeze.

Have you ever struggled with stiff, unyielding ropes that refuse to cooperate? With double braided nylon ropes, those frustrations become a thing of the past. Their pliable nature makes them a joy to work with, whether you're rigging a sailboat, setting up a climbing anchor, or securing a load on your truck. For more details on the benefits of double braided nylon ropes in offroad and marine applications, click here.

Abrasion Resistance and Durability

Imagine a rope that can withstand the harshest conditions without showing signs of wear and tear. That's the reality with double braided nylon ropes. Their tightly braided construction creates a dense, abrasion-resistant surface that can endure rough treatment and harsh environments. The outer braided jacket acts as a protective shield, safeguarding the inner core from abrasion and prolonging the rope's lifespan.

Whether you're scaling rugged terrain, working on a construction site, or braving the elements at sea, these ropes are built to last. Their durability and resistance to environmental factors like UV radiation, moisture, and chemicals make them a reliable choice for outdoor adventures and industrial applications alike.

Shock Absorption and Stretch

In many situations, a rope's ability to absorb shocks and stretch can mean the difference between safety and disaster. Double braided nylon ropes excel in this area, thanks to their moderate stretch capability. This inherent elasticity allows the rope to dissipate sudden forces or impacts, preventing damage to the rope itself or the equipment it's attached to.

Imagine scaling a rock face, and your climbing partner takes an unexpected fall. The stretch in your double braided nylon rope helps cushion the impact, protecting both of you from harm. Or picture a scenario where a heavy load shifts unexpectedly during transportation – the rope's shock-absorbing properties ensure that the load is secured without snapping or breaking.

Of course, it's important to strike a balance between stretch and strength. Double braided nylon ropes achieve this equilibrium, maintaining their load-bearing capacity while providing just enough give to absorb shocks and prevent sudden failures.

Coated Steel Cable vs. Double Braided Nylon Rope: A Comprehensive Comparison

When it comes to selecting the right cable or rope for your specific needs, understanding the key differences between coated steel cables and double braided nylon ropes can be a game-changer. These two materials, while both remarkably durable, offer distinct advantages that cater to different applications and environments.

The Advantages of Steel Cable Coatings

Steel cables are renowned for their exceptional strength and load-bearing capacity. However, when exposed to harsh environments, they can be susceptible to corrosion, abrasion, and other forms of damage. That's where coatings come into play, offering an extra layer of protection and enhancing the cable's performance.

- Nylon coatings – Nylon coatings provide superior abrasion resistance, shielding the steel core from wear and tear caused by friction. They also offer improved UV protection, preventing premature degradation from sunlight exposure.

- PVC coatings – PVC (polyvinyl chloride) coatings are resistant to chemicals, oils, and solvents, making them ideal for industrial settings or marine environments where exposure to these substances is common.

- Galvanized coatings – Galvanized coatings, typically made of zinc, offer excellent corrosion resistance, protecting the steel cable from rust and prolonging its lifespan in outdoor or marine applications.

Coated steel cables are a popular choice for applications that require high tensile strength, durability, and resistance to harsh conditions, such as construction sites, mining operations, and offshore platforms. For a detailed comparison between strong ropes and wire ropes, click here.

Exploring the Strength and Flexibility of Double Braided Nylon Rope

Double braided nylon ropes are a true marvel of engineering, combining exceptional strength with unmatched flexibility and versatility. Their construction features a tightly braided nylon core encased within an outer braided jacket or sleeve, resulting in a rope that can handle even the most demanding tasks.

Have you ever struggled with ropes that are too stiff or rigid to work with? Double braided nylon ropes eliminate that frustration, offering a level of pliability that makes them a joy to handle. Whether you're rigging a sailboat, setting up a climbing anchor, or securing a load, these ropes bend and conform to your needs with ease.

But don't let their flexibility fool you – double braided nylon ropes are incredibly strong and durable. The nylon fibers used in their construction boast impressive tensile strength, allowing these ropes to withstand substantial loads and stress without compromising their integrity.

Furthermore, their tight braided construction creates a dense, abrasion-resistant surface that can endure rough treatment and harsh environments. The outer braided jacket acts as a protective shield, safeguarding the inner core from abrasion and prolonging the rope's lifespan.

Double braided nylon ropes excel in shock absorption, thanks to their moderate stretch capability, making them a reliable choice for outdoor adventures and industrial applications where safety is paramount.

Whether you're scaling rugged terrain, working on a construction site, or braving the elements at sea, double braided nylon ropes are built to withstand the toughest challenges, offering a perfect balance of strength, flexibility, and durability.

Applications of Plastic Coated Steel Cables and Double Braided Nylon Ropes

When it comes to selecting the right cable or rope for your specific needs, understanding their diverse applications is key. Plastic coated steel cables and double braided nylon ropes have carved out their own niches, each excelling in different scenarios based on their unique properties and strengths.

High-Friction Applications for Nylon Coated Cables

Have you ever watched a crane operator effortlessly maneuver heavy loads with precision? Chances are, they're relying on the exceptional performance of nylon coated steel cables. These cables are engineered to thrive in high-friction environments, where abrasion and heat generation are constant concerns.

- Overhead lifting and rigging – Nylon coated cables are the go-to choice for industries like construction, manufacturing, and mining, where heavy equipment and machinery are routinely lifted and maneuvered.

- Winches and pulleys – The smooth nylon coating minimizes friction, reducing wear and tear on cables as they run over pulleys and through winches, ensuring long-lasting performance.

- Harsh industrial environments – Whether it's a steel mill, a power plant, or a mining operation, nylon coated cables can withstand the heat, abrasion, and demanding conditions of these industrial settings.

Imagine the chaos that would ensue if a cable failed during a critical lift or operation. With nylon coated steel cables, you can have peace of mind knowing that your equipment is protected and your operations can run smoothly, even in the most demanding environments.

Plastic Coated Wire Ropes for Outdoor Use

When it comes to outdoor applications, plastic coated wire ropes are the unsung heroes, providing durability and weather resistance in the face of Mother Nature's wrath. From scorching sun to driving rain, these ropes are built to endure.

- Security and fencing – Plastic coated wire ropes are a popular choice for security cables, guardrails, and fencing, thanks to their resistance to corrosion and UV radiation.

- Marine and coastal environments – Whether you're docking a boat or setting up a beach volleyball net, plastic coated ropes can withstand the harsh saltwater and coastal conditions without succumbing to rust or degradation.

- Adventure sports and outdoor recreation – Rock climbers, zip-liners, and outdoor enthusiasts rely on the weather-resistant properties of plastic coated ropes to ensure their safety and enjoyment, no matter the conditions.

Imagine the frustration of having to constantly replace cables or ropes due to weather damage. With plastic coated wire ropes, you can enjoy peace of mind knowing that your equipment is built to last, even when exposed to the harshest outdoor elements.

When it comes to double braided nylon ropes, their versatility knows no bounds. From marine applications to adventure sports, these ropes are trusted companions for those who demand strength, flexibility, and weather resistance all in one package.

- Sailing and boating – Double braided nylon ropes are a staple in the marine industry, providing the perfect blend of strength, flexibility, and resistance to saltwater and UV radiation.

- Rock climbing and mountaineering – Climbers rely on the durability and shock-absorbing properties of double braided nylon ropes to keep them safe on even the most challenging ascents. For a comprehensive overview of effective rope solutions for rock climbing, discover more here.

- Arborist and tree care – Arborists and tree care professionals trust double braided nylon ropes for their strength and flexibility, which are essential when working in precarious positions among branches and limbs.

Have you ever found yourself in a situation where a rope's performance could mean the difference between success and disaster? With double braided nylon ropes, you can rest assured that you have a reliable and trustworthy companion by your side, no matter the challenge you face.

Whether you're working on a construction site, navigating the high seas, or exploring the great outdoors, understanding the unique applications of plastic coated steel cables and double braided nylon ropes can help you make informed decisions and ensure that your operations run smoothly and safely.

Discover More: Which Cable is Right for You?

Choosing between nylon coated steel cable and double braided nylon rope depends on understanding their unique advantages and applications. Coated steel cables offer high strength, abrasion resistance, and suitability for heavy-duty and outdoor use, making them ideal for industrial machinery, marine operations, and adventure sports. In contrast, double braided nylon ropes are lightweight, flexible, and excellent at absorbing shock, making them perfect for marine applications and recreational activities. Consider your specific needs and the environmental factors at play to select the best option for your tasks. Fill in the form above to get customised advice and solutions tailored to your requirements.