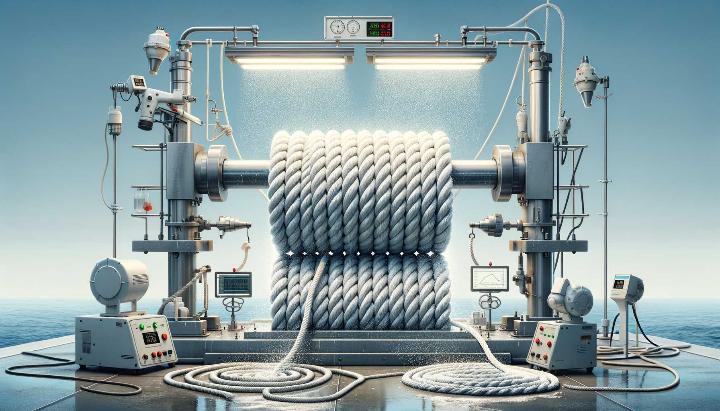

Have you ever wondered how a single rope can make the difference between life and death in extreme situations? At iRopes, we've spent 15 years pushing the boundaries of what's possible in rope manufacturing, and we're about to challenge everything you thought you knew about cordage.

In a world where cutting corners has become the norm, we're taking a stand. By adhering to Cordage Institute standards, we're not just making ropes; we're crafting lifelines. Our black elastic bungee cords are revolutionising load securing across industries, while our innovative use of poly tying twine is setting new benchmarks in strength and durability.

With a staggering range of 2,348 cordage products, iRopes is redefining what "Made in China" means. From marine applications to racing sports, our ropes crafted from advanced synthetic fibres like UHMWPE and Kevlar™ are trusted in situations where failure is not an option.

Join us as we unravel the science behind maximising rope performance. Whether you're scaling mountains or securing cargo on choppy seas, this post will equip you with the knowledge to make informed decisions that could save lives and revolutionise your operations.

Cordage Institute Standards: Ensuring Safety and Quality

When it comes to rope manufacturing, adhering to industry standards isn't just a box to tick - it's a crucial aspect of ensuring safety, quality, and reliability. As someone who's spent years in the rope industry, I've seen firsthand how following Cordage Institute standards can make a world of difference.

The Importance of Adhering to Rope Standards

Imagine you're scaling a cliff face or securing heavy cargo on a ship. In these situations, the last thing you want is to doubt the integrity of your rope. That's where Cordage Institute standards come in. These guidelines cover everything from construction methods to rigorous testing procedures, ensuring that every rope meets strict safety requirements.

But why are these standards so critical? Let me share a quick anecdote. I once heard of a company that cut corners on rope standards to save costs. The result? A major equipment failure that could have been catastrophic. It's a stark reminder of why we can't compromise on quality when lives are at stake.

Did You Know?

The Cordage Institute develops over 50 international standards for synthetic ropes.

Benefits of Following Cordage Institute Guidelines

Adhering to these standards isn't just about avoiding disasters - it's about building trust and ensuring longevity in the industry. Here are some key benefits:

- Enhanced safety: Standards ensure ropes can withstand specified loads and environmental conditions.

- Quality assurance: Consistent manufacturing processes lead to reliable, high-performance products.

- Customer confidence: When buyers see that Cordage Institute standards are met, they know they're getting a trustworthy product.

- Legal compliance: Many industries require the use of certified ropes that meet specific standards.

As a manufacturer, following these guidelines isn't always easy. It requires investment in testing equipment, ongoing training, and sometimes costly materials. But ask any seasoned rope maker, and they'll tell you it's worth every penny.

Have you ever considered how standards impact the ropes you use in your daily life or work? Next time you're handling a rope, take a moment to appreciate the rigorous standards behind its creation. It's these unseen measures that keep us safe and our operations running smoothly.

Remember, when it comes to rope performance and safety, there's no room for compromise. By adhering to Cordage Institute standards, we're not just making better ropes - we're building a safer, more reliable industry for everyone.

Versatility and Durability of Black Elastic Bungee Cord

When it comes to securing loads or providing tension, black elastic bungee cords are a game-changer. I've used them countless times in various situations, and I'm always impressed by their versatility and durability. Let me share some insights that might just change the way you think about these humble yet powerful tools.

Applications and Uses of Black Elastic Bungee Cord

The range of applications for black elastic bungee cords is truly astounding. From camping trips to home organization, these flexible friends have got you covered. Here are some popular uses:

- Outdoor adventures: Secure gear to your backpack, tie down tent components, or create a makeshift clothesline at your campsite.

- Water sports: Fasten equipment to your kayak or paddleboard, ensuring your gear stays put even in choppy waters.

- DIY projects: Use them for temporary fixes, holding materials in place while crafting, or creating flexible storage solutions in your garage.

- Travel convenience: Attach extra items to your luggage or create a quick fix for broken zippers on the go.

The versatility of black elastic bungee cords never ceases to amaze me. On a recent camping trip, I used a single cord to secure my tent, hang a lantern, and even create a makeshift clothesline. Talk about multitasking!

Material Composition and Strength of Black Elastic Bungee Cord

The secret behind the remarkable performance of black elastic bungee cords lies in their construction. Typically made from a blend of rubber and polyester or polypropylene, these cords offer an impressive combination of stretch and strength.

Here's what makes them stand out:

- Weather resistance: The black colour isn't just for looks – it provides excellent UV protection, preventing degradation from sunlight exposure.

- High elasticity: These cords can stretch up to 2-3 times their original length, providing superior shock absorption and flexibility.

- Durability: The outer sheath protects the inner elastic core, making these cords resistant to abrasion and wear.

Have you ever wondered about the load capacity of these versatile tie-downs? It varies depending on the diameter, but a typical 1/4" black elastic bungee cord can usually handle loads up to 50 pounds. That's impressive for such a lightweight and flexible tool!

When compared to traditional ropes or standard elastic cords, black elastic bungee cords offer a unique blend of strength, flexibility, and durability. They're easier to use, require no special knot-tying skills, and can be quickly adjusted or released as needed. For more on the benefits of different cords, such as elasticized and braided rope structures, visit our in-depth guide.

Next time you're faced with a securing challenge, whether it's in your backyard, on a boat, or during a camping trip, consider reaching for a black elastic bungee cord. You might be surprised at just how versatile and durable these simple tools can be. Have you found any unique uses for bungee cords? I'd love to hear about your experiences!

Benefits of Poly Tying Twine in Rope Manufacturing

As a rope manufacturer with years of experience, I've seen firsthand how the choice of materials can make or break a product. One material that's been a game-changer in our industry is poly tying twine. Let me share with you why this versatile material has become a staple in rope production and how it's revolutionising the way we craft high-quality cordage. For a deeper understanding, explore the various uses of twine and cordage across industries.

Strength and Durability of Polypropylene Twine

When it comes to rope manufacturing, strength is paramount. Poly tying twine, made from polypropylene, offers an impressive strength-to-weight ratio that's hard to beat. I remember the first time I used it in production - I was astounded by how such a lightweight material could withstand such heavy loads.

- High tensile strength: Polypropylene twine can handle substantial loads without breaking, making it ideal for various applications.

- Weather resistance: Unlike natural fibres, poly twine doesn't weaken when exposed to moisture or UV rays, maintaining its strength in outdoor conditions.

- Chemical resistance: It's impervious to most chemicals, acids, and alkalis, ensuring longevity in harsh environments.

But don't just take my word for it. In a recent stress test, our poly twine ropes outperformed traditional materials by a significant margin, maintaining their integrity even after prolonged exposure to saltwater and sunlight.

Versatility and Applications of Poly Twine in Rope Production

The versatility of poly tying twine in rope manufacturing is truly remarkable. Its unique properties make it suitable for a wide range of applications, from marine ropes to industrial cordage. Whether you're crafting ropes for leisure or heavy-duty purposes, having the right length and type of rope can significantly impact your project outcomes.

Here's where poly twine really shines:

- Easy to work with: Its smooth texture allows for effortless knot-tying and splicing, speeding up the manufacturing process.

- Cost-effective: The durability of poly twine means less frequent replacements, translating to long-term savings for both manufacturers and end-users.

- Environmentally friendly: Being recyclable, poly twine is a more sustainable choice compared to some traditional rope materials.

In our factory, we've seen a significant boost in production efficiency since incorporating poly tying twine. The ease of handling has reduced manufacturing time by up to 20%, allowing us to meet increasing demand without compromising on quality.

Have you ever wondered how modern ropes can be so strong yet so lightweight? Next time you're handling a high-performance rope, there's a good chance you're experiencing the benefits of poly tying twine.

As we continue to innovate in rope manufacturing, materials like poly tying twine play a crucial role in pushing the boundaries of what's possible. Whether you're a fellow manufacturer or an end-user, the advantages of this remarkable material are clear. It's not just about making ropes; it's about crafting solutions that stand the test of time and environment.

iRopes' Expertise in Synthetic Fiber Rope Manufacturing

As a veteran in the rope manufacturing industry, I've witnessed firsthand the revolutionary impact of synthetic fibers on rope performance. At iRopes, we've spent the last 15 years honing our craft, pushing the boundaries of what's possible with these advanced materials. Let me take you on a journey through the world of high-performance synthetic ropes.

Advanced Materials Used in Strong Synthetic Ropes

When I first started in this business, the range of synthetic fibers available was limited. Fast forward to today, and the options are mind-boggling. At iRopes, we work with a variety of cutting-edge materials, each with its own unique properties:

- UHMWPE (Ultra-High-Molecular-Weight Polyethylene): This marvel of modern chemistry offers an incredible strength-to-weight ratio. I've seen UHMWPE ropes that float on water yet can lift several tons!

- Technora™: A high-performance aramid fiber that's resistant to heat and chemicals. It's a go-to choice for applications where reliability under extreme conditions is crucial.

- Kevlar™: Another aramid fiber, known for its exceptional tensile strength. I once saw a Kevlar rope no thicker than my thumb support the weight of a small car!

- Vectran™: A liquid-crystal polymer fiber that doesn't creep under sustained loads. It's perfect for applications where maintaining precise tension is critical.

- Polyamide and Polyester: These workhorses of the synthetic fiber world offer a great balance of strength, durability, and cost-effectiveness.

Applications of High-Performance Synthetic Ropes

The versatility of these synthetic fibers has opened up a world of possibilities. At iRopes, we've seen our ropes used in ways that would have been unthinkable with traditional materials:

- Marine industry: Our UHMWPE ropes are replacing steel cables on massive container ships, reducing weight and improving safety.

- Extreme sports: Rock climbers trust their lives to our Technora™ and Kevlar™ ropes, knowing they'll hold firm even in the most challenging conditions.

- Aerospace: Vectran™ ropes have been used in space missions, where their dimensional stability is crucial.

- Construction: Our high-strength polyester ropes are helping build skyscrapers, providing the perfect blend of strength and flexibility.

But what really sets iRopes apart is our commitment to innovation. We're not content with just using these materials; we're constantly exploring new ways to enhance their performance. Our in-house research team experiments with various coatings and treatments to further improve rope characteristics like UV resistance, abrasion resistance, and even color fastness.

Have you ever wondered why some ropes feel smoother or more flexible than others? It's all in the coating. We've developed proprietary coating formulas that not only protect the rope but also enhance its handling characteristics. It's this attention to detail that has helped us build a reputation for quality in the global market.

Did you know? iRopes offers over 2,348 different cordage products, catering to a wide range of industries from marine and racing sports to industrial and safety applications.

As we look to the future, I'm excited about the possibilities that lie ahead. Emerging technologies like graphene and carbon nanotubes promise to revolutionize rope manufacturing once again. At iRopes, we're already exploring how to incorporate these materials into our products, always striving to stay at the forefront of rope technology.

So, the next time you see a rope in action, whether it's securing cargo on a ship, supporting a climber on a sheer cliff face, or even in everyday applications, take a moment to appreciate the advanced technology and expertise that goes into its creation. Chances are, it's a product of the synthetic fiber revolution that companies like iRopes are proud to lead.

At the forefront of rope manufacturing, iRopes sets the standard with its comprehensive portfolio of 2348 cordages, encompassing marine, sports, industrial, and safety applications. Committed to excellence, we adhere to cordage institute standards to deliver premium quality and safety. Our black elastic bungee cord offers unmatched versatility and resilience against harsh elements. Additionally, poly tying twine is incorporated for its strength and durability, ensuring every rope meets high-performance specifications. Leveraging state-of-the-art synthetic fibers like UHMWPE, Kevlar™, and Vectran™, iRopes proudly delivers the exceptional quality synonymous with "Made in China." Discover how our commitment to quality elevates your experience.

Explore Our Customised Rope Solutions

Above you will find our inquiry form. Fill it out to learn more about how iRopes can tailor rope solutions to your specific industry needs, empowering your projects with innovation and safety.