Have you ever wondered why some cables seem indestructible while others wear out in no time? The secret lies in the world of vinyl covered wire rope and steel catalogues. At iRopes, we've spent 15 years mastering the art of crafting high-performance cordages that stand the test of time, no matter the industry or application.

Imagine a rope that not only withstands harsh marine environments but also adds a sleek, professional touch to your yacht. Or picture a cable that can handle the rigours of industrial use while prioritising worker safety. That's the power of vinyl covered wire rope – and it's just the beginning of what iRopes has to offer.

In this comprehensive guide, we'll dive deep into the world of vinyl covered wire rope and steel catalogues. You'll discover why our extensive range of 2,348 cordage types, crafted from cutting-edge synthetic fibres like UHMWPE, Technora™, and Kevlar™, is revolutionising industries from marine and racing sports to industrial and safety applications. We'll explore how our commitment to innovation and quality is changing the perception of "Made in China" products, one high-performance rope at a time.

Whether you're a seasoned professional or a curious enthusiast, this blog post will equip you with the knowledge to choose the perfect rope for your specific needs. Get ready to unravel the mysteries of vinyl covered wire rope, navigate our steel catalogue with confidence, and discover how iRopes can elevate your projects to new heights. Let's begin this journey into the fascinating world of high-performance cordages!

Understanding Vinyl Covered Wire Rope

When it comes to versatile and durable rigging solutions, vinyl covered wire rope stands out as a game-changer in various industries. Let's dive into the world of this remarkable product and explore why it's becoming increasingly popular among professionals and DIY enthusiasts alike.

Benefits of Vinyl Coated Cable

Vinyl coated wire rope offers a myriad of advantages that set it apart from its uncoated counterparts. Have you ever wondered why some cables seem to withstand the test of time better than others? The secret lies in the protective vinyl coating.

- Enhanced durability: The vinyl layer acts as a shield, protecting the wire rope from corrosion, abrasion, and chemical exposure. This means your cables will last longer, even in harsh environments.

- Improved safety: The smooth surface of vinyl coated cables reduces the risk of cuts and injuries during handling, making them safer for workers and DIY enthusiasts.

- Aesthetic appeal: Available in various colours, vinyl coated wire ropes can blend seamlessly with your project's design or stand out for safety purposes.

- Reduced maintenance: The protective coating minimises the need for frequent lubrication and cleaning, saving you time and money in the long run.

Types and Applications of Vinyl Coated Wire Rope

The versatility of vinyl coated wire rope makes it suitable for a wide range of applications. From industrial uses to home improvement projects, these cables are making waves across various sectors.

In the marine industry, for instance, vinyl coated stainless steel cables are prized for their resistance to saltwater corrosion. Have you ever noticed the sleek, coloured cables on a yacht? Chances are, they're vinyl coated for both aesthetics and longevity.

For outdoor applications, such as playground equipment or animal enclosures, vinyl coated galvanised cables offer the perfect blend of strength and weather resistance. The coating not only protects the cable but also provides a softer touch, making it safer for children and animals.

Selecting the Right Vinyl Covered Wire Rope

Choosing the perfect vinyl covered wire rope for your project doesn't have to be a daunting task. Here's a simple guide to help you make the right decision:

- Determine the required strength based on your load capacity needs.

- Consider the environment where the cable will be used (indoor, outdoor, marine, etc.).

- Decide on the appropriate diameter and length for your application.

- Choose a colour that suits your project's aesthetic or safety requirements.

Remember, the thickness of the vinyl coating can affect the overall diameter of the cable. Always factor this in when selecting fittings or planning your installation.

At iRopes, we offer a comprehensive range of vinyl covered wire ropes to suit every need. With our 15 years of experience in rope manufacturing, we can help you find the perfect solution for your project, whether it's for marine use, industrial applications, or DIY endeavours. Discover more about the premium quality rope solutions we offer, tailored to various industries.

Did you know? iRopes offers customisation options for vinyl covered wire ropes, including specific colours, diameters, and coating thicknesses to meet your unique requirements.

Ready to explore the world of vinyl covered wire ropes? Contact iRopes today to discuss your specific needs and discover how our high-quality, "Made in China" products can elevate your next project.

Exploring iRopes' Vinyl Covered Cable Selection

At iRopes, we pride ourselves on offering a comprehensive range of vinyl covered cables that cater to diverse industry needs. Our 15 years of experience in rope manufacturing has allowed us to perfect our craft, ensuring that every cable we produce meets the highest standards of quality and durability.

Types and Applications of Vinyl Coated Wire Rope

When it comes to vinyl coated wire rope, one size certainly doesn't fit all. That's why we offer a variety of options to suit different applications. Let's take a closer look at some of our most popular types:

- 1/16" 7x7 Vinyl Coated Cable: Ideal for light-duty applications, this flexible cable is perfect for small-scale rigging and decorative purposes.

- 3/32" 7x7 Vinyl Coated Cable: A step up in strength, this cable is commonly used in marine environments and outdoor structures.

- 1/8" 7x19 Vinyl Coated Cable: This versatile option offers a balance of strength and flexibility, making it suitable for a wide range of industrial applications.

Each of these cables is available in various colours, allowing you to choose the perfect match for your project's aesthetic or safety requirements. But what sets vinyl coated cables apart from their non-coated counterparts?

Did you know? Vinyl coated cables can extend the lifespan of your wire rope by up to 15 years when properly maintained!

The vinyl coating acts as a protective barrier, shielding the steel core from corrosion, UV damage, and abrasion. This not only increases the longevity of the cable but also makes it safer and more pleasant to handle. Plus, the smooth surface of vinyl coated cables reduces friction, making them ideal for pulley systems and other dynamic applications.

Choosing the Right Vinyl Covered Cable for Your Project

Selecting the perfect vinyl covered cable can seem daunting, but it doesn't have to be. Here's a simple guide to help you make the right choice:

- Determine the required strength based on your load capacity needs.

- Consider the environment where the cable will be used (indoor, outdoor, marine, etc.).

- Decide on the appropriate diameter and construction (7x7, 7x19) for your application.

- Choose a colour that suits your project's aesthetic or safety requirements.

Remember, the thickness of the vinyl coating can affect the overall diameter of the cable. Always factor this in when selecting fittings or planning your installation.

At iRopes, we understand that every project is unique. That's why we offer customisation options for our vinyl covered cables. Whether you need a specific colour, diameter, or coating thickness, we're here to help you find the perfect solution.

Ready to elevate your next project with high-quality, durable vinyl covered cables? Contact iRopes today, and let our expert team guide you through the selection process. With our commitment to excellence and the renowned quality of "Made in China" products, you can trust that you're investing in cables that will stand the test of time.

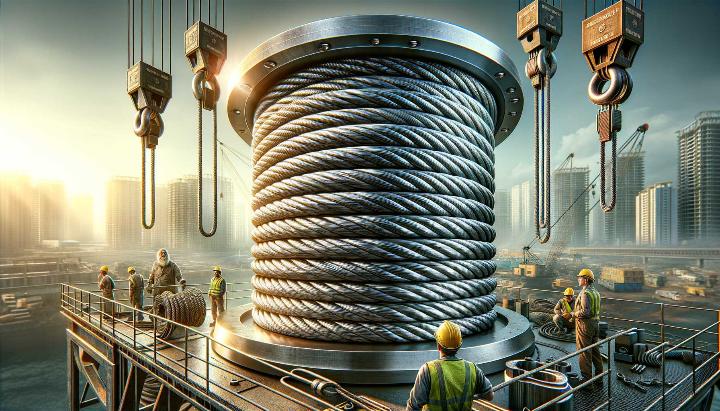

Navigating iRopes' Steel Wire Rope Catalogue

As you delve into the world of steel wire ropes, you'll quickly realise that not all ropes are created equal. At iRopes, we've poured our 15 years of expertise into crafting a comprehensive steel wire rope catalogue that caters to a wide range of industries and applications. Let's take a closer look at what makes our catalogue stand out and how you can navigate it to find the perfect rope for your needs.

Types of Steel Wire Ropes and Their Applications

Steel wire ropes come in various classifications, each designed for specific purposes. Have you ever wondered why some ropes seem more flexible than others? The secret lies in their construction. Here are some common types you'll find in our catalogue:

- 6x19 Classification: This versatile rope offers a good balance between flexibility and abrasion resistance. It's ideal for general-purpose lifting and rigging applications.

- 6x36 Classification: With more wires per strand, this rope provides increased flexibility, making it perfect for applications that require frequent bending, such as on cranes and winches.

- IWRC (Independent Wire Rope Core): These ropes feature a steel core that enhances strength and reduces stretch, making them suitable for heavy-duty lifting operations.

Choosing the right rope type can significantly impact your project's success. For instance, I once worked on a marine project where we initially used a standard 6x19 rope. However, we quickly realised that the frequent bending around pulleys was causing premature wear. Switching to a 6x36 classification dramatically improved the rope's lifespan and performance.

Navigating Wire Rope Specifications and Standards

Understanding wire rope specifications is crucial for selecting the right product. Here are some key factors to consider:

- Diameter: This affects the rope's strength and compatibility with your equipment.

- Tensile strength: Measured in Newtons per square millimetre (N/mm²), this indicates the rope's maximum load-bearing capacity.

- Flexibility: Determined by the number of wires per strand, this affects the rope's ability to bend without damage.

One of the most critical specifications is the Safe Working Load (SWL). Did you know there's a simple formula to calculate it? For steel wire ropes, the SWL in tons is approximately equal to the square of the rope's diameter (in inches) multiplied by eight. For example, a 1-inch diameter rope would have an SWL of about 8 tons (1² x 8 = 8).

Remember: Always consult the manufacturer's specifications for accurate SWL values, as they can vary based on the rope's construction and materials.

At iRopes, we ensure all our steel wire ropes meet or exceed industry standards, including ISO certifications. This commitment to quality gives you peace of mind, knowing that the rope you choose is up to the task, whether you're working in construction, mining, or marine applications.

Navigating our steel wire rope catalogue might seem daunting at first, but with these guidelines and our expert support, you'll be well-equipped to make the right choice. Remember, the perfect rope is out there – it's just a matter of finding the one that fits your specific needs like a glove.

Have questions about our steel wire rope catalogue or need help selecting the right product for your project? Don't hesitate to reach out. At iRopes, we're not just selling ropes; we're partnering with you to ensure your success. Let's find the perfect steel wire rope solution together!

iRopes: Leading Expertise in Rope Manufacturing

When it comes to high-performance cordages, iRopes stands out as a beacon of excellence in China's rope manufacturing industry. With 15 years of experience under our belt, we've honed our craft to perfection, offering a diverse range of ropes that cater to various industries and applications.

15 Years of Experience in China's Rope Industry

Our journey in the rope manufacturing sector has been nothing short of remarkable. From humble beginnings to becoming a leading player in the industry, iRopes has consistently pushed the boundaries of what's possible in rope technology. But what exactly sets us apart?

- Continuous innovation: We've invested heavily in research and development, constantly improving our manufacturing processes and materials.

- Quality assurance: Our rigorous quality control measures ensure that every rope leaving our facility meets the highest standards.

- Industry recognition: We've been honoured with several awards for our contributions to the Chinese rope manufacturing sector.

I remember when we first started out, the concept of "Made in China" often carried negative connotations. But over the years, we've worked tirelessly to change that perception, one high-quality rope at a time. Today, our products are sought after by clients worldwide, a testament to our commitment to excellence.

Wide Range of High-Performance Cordages

At iRopes, we pride ourselves on offering an extensive selection of 2348 cordage types. But what does this mean for you, our valued customer? It means that whether you're outfitting a yacht, setting up safety equipment for a construction site, or gearing up for an extreme sports event, we've got you covered.

Our high-performance ropes are crafted from strong synthetic fibres, each chosen for its unique properties:

- UHMWPE: Ultra-high-molecular-weight polyethylene, known for its incredible strength-to-weight ratio.

- Technora™: A heat-resistant aramid fibre that's perfect for applications requiring high tensile strength.

- Kevlar™: Another aramid fibre, renowned for its high tensile strength-to-weight ratio.

- Vectran™: A high-performance multifilament yarn spun from liquid crystal polymer, offering excellent creep resistance.

- Polyamide and polyester: Versatile synthetic fibres suitable for a wide range of applications.

But it's not just about the materials. Our research and development team works tirelessly to create ropes that meet the specific needs of different industries. Have you ever wondered how a rope used in marine applications differs from one used in industrial settings? It's all in the design, construction, and coating.

Did you know? Our coating options can enhance your rope's performance, providing additional protection against UV rays, abrasion, and even fire resistance in some cases.

At iRopes, we're not just manufacturing ropes; we're crafting solutions. Whether you need a rope that can withstand extreme temperatures, resist chemical corrosion, or provide unparalleled strength, we've got the expertise to deliver.

Ready to elevate your project with high-performance cordages? Let's talk about your specific needs and how iRopes can provide the perfect rope solution. After all, in the world of ropes, one size definitely doesn't fit all!

```htmlDiscover the exceptional capabilities of iRopes, a renowned rope manufacturer in China with 15 years of expertise, offering a steel wire rope catalogue that showcases a diverse array of vinyl covered wire rope solutions. Our vinyl covered cable products stand apart due to their enhanced durability, aesthetic appeal, and reduced maintenance needs, making them ideal for industries ranging from marine to DIY projects. iRopes provides a wide selection of customisation options to ensure that your rope solutions perfectly meet your specific requirements, capitalising on strong synthetic fibres and advanced coating techniques, truly embodying the quality of "Made in China." Our commitment to quality and innovation makes us your go-to choice for customised rope solutions.

Contact iRopes for Your Vinyl Wire Needs

Submit your inquiries through the form above to start tailoring your perfect rope solution. Our experts will assist you in selecting the ideal products from our vinyl covered cable and steel wire rope catalogue, enhancing your project's success.

```