Have you ever wondered how a simple piece of rope can revolutionise entire industries? Enter the world of braided nylon rope - a marvel of modern engineering that's changing the game for professionals and DIY enthusiasts alike. At iRopes, we've seen firsthand how this versatile material has become the unsung hero in fields ranging from off-road adventures to yachting, and even defence applications.

But what makes braided nylon rope so special? Imagine a material that gains strength when wet, can stretch up to 20% without breaking, and outlasts its competitors in the harshest environments. That's the power of nylon, and when it's expertly braided, it becomes an unstoppable force in the world of cordage.

In this post, we'll dive deep into the art of braiding nylon rope and explore how the right rope braiding tool can elevate your projects to new heights. Whether you're a wholesaler looking for the perfect OEM solution or a hobbyist eager to create custom ropes, you'll discover why mastering this skill is essential in today's rope-reliant world. Get ready to unravel the secrets of superior rope craftsmanship and learn how a rope braiding machine can transform your rope-making process.

Understanding Braided Nylon Rope

Have you ever marvelled at the strength and versatility of a well-crafted rope? As someone who's spent years working with various types of cordage, I can tell you that braided nylon rope is truly a marvel of modern engineering. Let's dive into the fascinating world of this essential tool and explore why it's become a go-to choice for so many industries and applications.

Types of Braided Nylon Rope

When it comes to braided nylon rope, there are two main types you'll encounter:

- Solid braid nylon: This type features a tight, uniform construction throughout the entire rope. It's incredibly strong and resistant to abrasion, making it perfect for heavy-duty applications.

- Double braid nylon: Imagine a rope within a rope - that's essentially what double braid is. It consists of a braided core surrounded by a braided sheath, offering an excellent balance of strength and flexibility.

Each type has its unique strengths, and choosing between them often comes down to the specific requirements of your project.

Properties and Advantages of Braided Nylon Rope

What makes braided nylon rope stand out from the crowd? Let me share some insights from my experience:

- Incredible strength-to-weight ratio: Nylon rope can support heavy loads without adding unnecessary bulk to your equipment.

- Impressive stretch capacity: Did you know that nylon rope can stretch up to 20% without losing its strength? This elasticity makes it excellent for absorbing shock loads.

- Exceptional durability: I've seen nylon ropes withstand harsh conditions that would quickly degrade other materials. Its resistance to abrasion, UV rays, and chemicals is truly remarkable.

- Water-friendly properties: Unlike some materials that weaken when wet, nylon actually gains strength when damp - a crucial feature for marine applications.

These properties make braided nylon rope an ideal choice for a wide range of uses, from heavy industrial applications to delicate craft projects.

Pro Tip: When selecting a braided nylon rope, always consider the specific demands of your project. Factors like load capacity, environmental conditions, and frequency of use should all play a role in your decision.

Whether you're rigging a sailboat, setting up a pulley system, or crafting a decorative piece, understanding the unique properties of braided nylon rope can help you make the most of this versatile material. In the next section, we'll explore some key techniques for braiding nylon rope yourself - an invaluable skill for any rope enthusiast!

Mastering the Art of Braiding Nylon Rope

As a seasoned rope craftsman, I can tell you that mastering the art of braiding nylon rope is both rewarding and practical. Whether you're a sailing enthusiast, a DIY lover, or simply curious about rope-making, learning these techniques can open up a world of possibilities. Let's dive into the essentials of nylon rope braiding and explore how you can create strong, durable ropes for various applications.

Techniques for Braiding 3-Strand Nylon Rope

The 3-strand braid is the foundation of rope-making, and it's where we'll start our journey. Here's how you can create a basic 3-strand nylon rope:

- Secure three equal lengths of nylon cord to a fixed point.

- Separate the strands and hold one in each hand, with the middle strand hanging free.

- Take the right strand and cross it over the middle strand.

- Then, take the left strand and cross it over the new middle strand.

- Repeat this process, alternating sides, while maintaining consistent tension.

Remember, practice makes perfect. As you work, you'll develop a rhythm that helps you create a uniform braid.

Advanced Splicing Methods for Nylon Rope

Once you've mastered the basic braid, it's time to level up with splicing techniques. Splicing allows you to join ropes or create loops, essential for many applications. Here's a quick guide to eye splicing:

- Unravel the rope end: Carefully separate the strands about 30 cm from the end.

- Form the loop: Bend the rope to create the desired loop size.

- Weave the strands: Tuck each unraveled strand under the main rope's strands, following a pattern.

- Taper and trim: Gradually reduce the number of tucks and trim excess for a smooth finish.

Splicing takes patience and practice, but the result is a strong, professional-looking connection that maintains the rope's integrity.

Pro Tip: When splicing nylon rope, use a fid or splicing needle to make tucking strands easier and more precise. This tool can significantly improve your splicing technique and the overall quality of your work.

As you continue to hone your skills, you'll find that braiding nylon rope becomes second nature. The versatility of nylon, combined with your newfound expertise, will allow you to create custom ropes for any project. Whether you're rigging a sailboat, creating a stylish pet leash, or crafting intricate macramé, the possibilities are endless. So grab some nylon cord, and let's start braiding!

Choosing the Best Rope Braiding Tool

As someone who's spent countless hours perfecting the art of rope braiding, I can't stress enough how crucial it is to have the right tools at your disposal. Whether you're a seasoned pro or just starting out, selecting the best rope braiding tool can make all the difference in the quality and efficiency of your work. Let's dive into the world of rope braiding tools and discover how to choose the perfect one for your needs.

Types of Rope Splicing Tools

When it comes to rope braiding and splicing, there's a tool for every job. Here are some essential tools you should know about:

- Fids: These tapered, hollow needles are the workhorses of rope splicing. They come in various sizes to match different rope diameters.

- Gripfids: A variation of the traditional fid, these tools have a grip handle for better control during splicing.

- Cord makers: Perfect for creating custom cords, these tools allow you to braid multiple strands into a single, strong cord.

Each tool has its unique advantages, and your choice will depend on the type of project you're tackling. For instance, when I'm working on a delicate sailing line, I always reach for my trusty fid to ensure precise splices.

Factors to Consider When Selecting a Braiding Tool

Choosing the right rope braiding tool isn't just about picking the shiniest gadget on the shelf. Here are some crucial factors to keep in mind:

- Rope diameter: The size of your rope will dictate the size of your tool. Remember, fid length is typically calculated as 21 times the rope diameter.

- Rope material: Different materials require different approaches. For example, braiding nylon rope might require a different tool than working with kernmantle rope.

- Durability: Look for tools made from high-quality materials like stainless steel or hard-wearing plastics.

- Ease of use: Especially for beginners, tools with ergonomic designs can make the learning process much smoother.

In my experience, investing in a versatile set of tools that can handle various rope types and diameters is always a smart move. It's saved me countless trips to the hardware store in the middle of projects!

Pro Tip: When starting out, consider purchasing a rope splicing kit. These often include a range of tools suitable for different rope types and diameters, giving you the flexibility to tackle various projects as your skills grow.

Remember, the best rope braiding tool is the one that feels comfortable in your hands and produces consistent results. Don't be afraid to experiment with different tools to find what works best for you. With the right tool and a bit of practice, you'll be creating professional-quality braids and splices in no time!

Exploring the Versatility of Braided Nylon Rope

As a rope enthusiast with years of experience in various industries, I've come to appreciate the incredible versatility of braided nylon rope. It's not just a simple cord; it's a powerhouse of strength and adaptability that has revolutionised countless fields. Let's dive into the world of this remarkable material and discover why it's become the go-to choice for professionals and hobbyists alike.

Strength and Durability of Nylon Rope

When it comes to strength, braided nylon rope is truly in a league of its own. I've seen it withstand conditions that would make other materials crumble. Here's what makes it stand out:

- Superior strength-to-weight ratio: Nylon rope can support heavy loads without adding unnecessary bulk to your equipment.

- Exceptional abrasion resistance: It can withstand rough surfaces and repeated use without showing significant wear.

- UV ray resistance: Unlike many synthetic materials, nylon rope maintains its integrity even after prolonged exposure to sunlight.

- Impressive longevity: With proper care, a quality braided nylon rope can last for years, even in demanding environments.

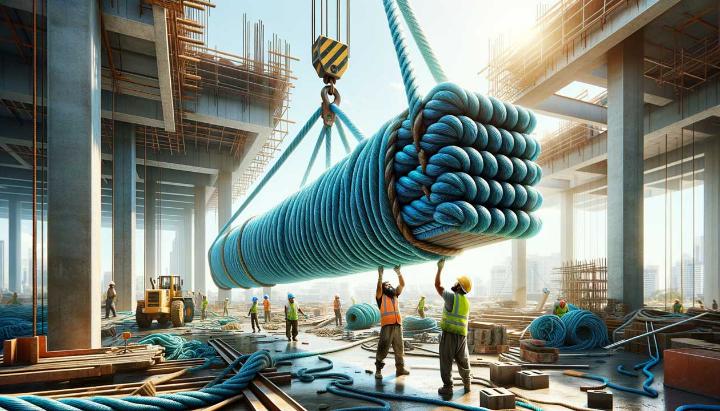

I once used a braided nylon rope to secure a heavy load on a construction site. Despite the sharp edges and constant movement, the rope held firm without a single fray. That's when I truly understood the meaning of industrial-strength cord.

Applications and Uses of Braided Nylon

The versatility of braided nylon rope is truly astounding. Here are just a few of the many applications I've encountered:

- Marine environments: From mooring large vessels to towing smaller boats, nylon rope is a staple in the maritime industry.

- Construction and industrial use: It's used in pulley systems, winches, and for lifting heavy loads safely and efficiently.

- Outdoor adventures: Climbers and campers rely on nylon rope for its strength and lightweight properties.

- Agriculture: Farmers use it for everything from securing livestock to bundling hay bales.

Have you ever considered how many times you've relied on nylon rope without even realising it? It's everywhere, quietly doing its job with remarkable efficiency.

Advantages Over Other Rope Materials

In my years of working with various rope materials, I've found that braided nylon consistently outperforms many alternatives. Here's why:

- Superior shock absorption: Nylon rope can stretch up to 20% of its length, absorbing dynamic loads that would snap other ropes.

- Excellent performance in wet conditions: Unlike natural fibres, nylon actually gains strength when wet, making it ideal for marine applications.

- Cost-effective longevity: While the initial cost might be higher than some materials, its durability makes it more economical in the long run.

- Versatility across temperatures: From freezing arctic conditions to scorching desert heat, nylon rope maintains its performance.

Pro Tip: When choosing between rope materials, consider the specific demands of your project. While braided nylon is versatile, there may be situations where alternatives like polyester or polypropylene are more suitable.

The versatility of braided nylon rope continues to amaze me, even after years in the industry. Whether you're a professional seeking a reliable industrial-strength cord or a DIY enthusiast looking for a multi-purpose solution, braided nylon rope is likely to exceed your expectations. Its combination of strength, durability, and adaptability makes it an invaluable tool across a wide range of applications. So, the next time you're faced with a challenging tying, securing, or lifting task, why not give braided nylon rope a try? You might just discover your new go-to material for all your rope-related needs. For further insights into maximizing rope strength, check out our article on innovative rope splicing tools that can enhance your projects.

Mastering the art of braiding nylon rope opens up endless possibilities, from industrial uses to recreational projects. With incredible strength-to-weight ratio, elasticity, and durability, braided nylon rope stands out as a versatile choice. Understanding types like solid braid and double braid nylon enhances your project outcomes. Choosing the right rope braiding tool, including dedicated rope braiding machines, plays a crucial role in achieving tight and consistent braids. This guide unravels key techniques and highlights the best tools, empowering you to harness the full potential of braided nylon rope in varied applications.

Get the Perfect Nylon Rope for Your Needs

The inquiry form above is your gateway to discovering the ideal rope braiding tool and customised rope solutions from iRopes. Fill it in to get expert recommendations tailored to your specific requirements and projects.