Have you ever wondered why some construction projects seem to defy gravity, with massive loads suspended in mid-air? The secret lies in the often-overlooked world of rigging rope. From towering cranes to intricate stage setups, quality rigging rope is the unsung hero that keeps our most ambitious projects safe and successful.

But here's the rub: finding the right rigging rope near you isn't always straightforward. With countless options flooding the market, how do you separate the wheat from the chaff? Whether you're searching for rope wholesale near me, rigging rope near me, or bulk rope near me, the choices can be overwhelming.

That's where we come in. As industry experts with years of experience, we're here to guide you through the maze of rigging rope options. In this comprehensive guide, we'll explore the crucial factors in selecting quality rigging rope, reveal insider tips for finding reliable local suppliers, and show you how to leverage wholesale options for cost-effective solutions.

Get ready to elevate your rigging game and ensure your projects stand tall - both literally and figuratively. Let's dive in and unravel the secrets of finding the perfect rigging rope near you.

Understanding Rigging Materials and Structures

When it comes to lifting and moving heavy loads, rigging is the unsung hero of countless industries. From construction sites to shipping yards, rigging plays a crucial role in ensuring safety and efficiency. Let's dive into the world of rigging materials and structures, shall we?

Essential Rigging Equipment and Hardware

Imagine walking onto a job site and seeing a dizzying array of ropes, cables, and chains. It might seem overwhelming at first, but each piece of equipment serves a specific purpose. Here's a quick rundown of some common rigging gear:

- Wire ropes: These sturdy cables are the workhorses of rigging, capable of handling immense loads.

- Slings: Versatile lifting tools that come in various materials, including synthetic fibres and wire rope.

- Shackles: These U-shaped connectors are essential for linking different components of a rigging system.

- Hooks: The business end of many rigging setups, hooks come in various shapes and sizes for different applications.

- Turnbuckles: Used to adjust tension in rigging systems, these nifty devices are invaluable for fine-tuning.

Choosing the right equipment for your project is crucial. Have you ever wondered how riggers decide which gear to use? It's all about understanding the job requirements and the specific properties of each tool.

Basic Rigging Safety Practices

Safety in rigging isn't just important – it's absolutely essential. One wrong move could lead to catastrophic consequences. That's why industry standards like OSHA, ASME, and ANSI regulations are the backbone of every rigging operation.

Always remember: The Working Load Limit (WLL) is your golden rule. Never exceed it, no matter how tempting it might be to push the limits.

Key safety practices include:

- Regular equipment inspections: Catching wear and tear early can prevent accidents.

- Proper load calculation: Understanding the weight and distribution of your load is crucial.

- Clear communication: Everyone on site should be on the same page about the rigging plan.

Have you ever been part of a rigging team? The synergy between the Designated Person, Competent Person, and Qualified Person is fascinating to watch. Each role is vital in ensuring a safe and successful operation.

Types of Rigging Systems and Structures

Rigging isn't one-size-fits-all. Different projects require different approaches. Here are some common rigging systems you might encounter:

- Dead Hung: A simple, static system often used in theatrical rigging.

- Counterweight: Balances the load with weights, making it easier to move heavy objects.

- Motorized: Uses motors for precise control, often seen in large-scale productions.

Each system has its strengths and ideal applications. The key is matching the right system to your specific project needs.

Understanding these rigging fundamentals is just the beginning. As you delve deeper into the world of rigging, you'll discover a rich tapestry of engineering, physics, and practical know-how. It's a field where precision meets raw power, and where safety is always the top priority.

So, the next time you see a towering crane or a complex stage setup, take a moment to appreciate the intricate rigging that makes it all possible. It's a testament to human ingenuity and the power of working together to achieve the seemingly impossible.

Identifying Reliable Sources for Bulk Rope Near You

When it comes to large-scale projects, finding a trustworthy bulk rope supplier can make all the difference. As someone who's spent years in the rigging industry, I've learned that the right source can save you time, money, and headaches. Let's dive into how you can find quality bulk rope suppliers near you.

Types of Bulk Rope and Their Applications

Before we jump into finding suppliers, it's crucial to understand the different types of rope available. In my experience, knowing your materials is half the battle in sourcing the right product.

- Nylon: Excellent for marine applications due to its strength and elasticity.

- Polypropylene: Ideal for outdoor use as it's lightweight and water-resistant.

- Natural fibres: Including manila, hemp, and cotton, often used in decorative or traditional applications.

I remember a project where we initially chose polypropylene for a marine application, only to switch to nylon after realising we needed better shock absorption. Understanding these nuances can save you from costly mistakes.

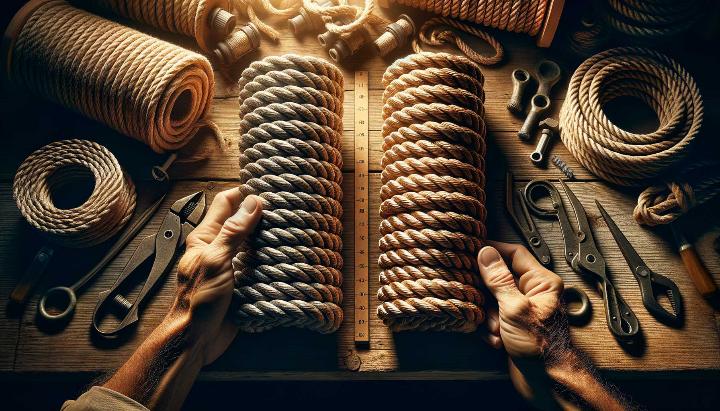

Evaluating Rope Quality and Suppliers

Now, let's talk about finding those reliable bulk rope suppliers near you. It's not just about the lowest price – quality and reliability are paramount. Here's a checklist I've developed over the years:

- Certifications matter: Look for suppliers with ISO 9001 certification or industry-specific standards.

- Ask for samples: Any reputable supplier should be willing to provide samples for testing.

- Check reviews and references: Don't just rely on testimonials on their website – dig deeper.

- Assess their knowledge: A good supplier should be able to advise you on the best rope for your specific needs.

Have you ever had a supplier go the extra mile for you? I once had a local supplier stay open late to help me with an urgent order. That level of service is invaluable in our industry.

Remember, finding a reliable bulk rope supplier near you is about building a relationship. Don't be afraid to ask questions and negotiate terms. A good supplier will be transparent about their processes and pricing.

As you embark on your search for quality bulk rope, keep these tips in mind. And don't forget – sometimes the best supplier isn't the closest one, but the one that best understands your needs. Happy sourcing!

Finding Specialized Rigging Rope for Your Needs

When it comes to rigging projects, using the right rope can make all the difference between success and failure. As someone who's spent years in the rigging industry, I've seen firsthand how crucial it is to select the perfect specialized rigging rope for each unique application. Let's dive into the world of specialized rigging ropes and explore how to find the best fit for your project.

Types of Rigging Rope for Specific Applications

The rigging rope market offers a diverse range of options, each with its own set of properties and ideal uses. Here's a breakdown of the most common types you'll encounter:

- Polyester rigging rope: Known for its excellent strength-to-weight ratio and low stretch, polyester is perfect for applications where minimal elongation is crucial.

- Nylon rigging rope: With its high elasticity and shock-absorbing properties, nylon is ideal for dynamic loads and marine environments.

- Polypropylene rigging rope: Lightweight and water-resistant, polypropylene is great for outdoor use and floating applications.

But it's not just about the material. The construction of the rope plays a significant role too. Have you ever wondered about the difference between single braid and double braid ropes?

Single braid ropes are more flexible and easier to splice, while double braid ropes offer superior strength and abrasion resistance. I once worked on a project where we initially chose a single braid rope, only to switch to a double braid when we realised we needed extra durability for the harsh conditions on site.

How to Choose the Right Specialized Rope for Your Project

Selecting the perfect rigging rope isn't just about picking the strongest option. It's about finding the right balance of properties for your specific needs. Here are some key factors to consider:

- Strength requirements: Determine the Working Load Limit (WLL) needed for your application.

- Environmental conditions: Consider exposure to UV rays, chemicals, or moisture.

- Rope diameter: Typically ranging from 1/2 inch to 22mm, choose based on your equipment compatibility.

- Stretch and elongation: Decide whether you need a low-stretch rope for precision or some elasticity for shock absorption.

Remember, it's not just about the rope itself. The right accessories can make a world of difference. For instance, using appropriate thimbles and terminations can significantly extend the life of your rigging setup.

Pro tip: When in doubt, always consult with a rigging professional. They can provide invaluable insights based on your specific project requirements.

Looking for specialized rigging rope in your area? Don't hesitate to reach out to local rigging supply stores or professional rigging equipment suppliers. They often stock a wide range of options, including specialized ropes like arborist bull ropes for tree work.

Remember, investing in high-quality, specialized rigging rope isn't just about getting the job done - it's about ensuring safety and efficiency in your operations. So take the time to research, ask questions, and choose wisely. Your future self (and your team) will thank you for it!

Cost-Effective Rope Solutions: Finding Wholesale Suppliers Near You

In the world of rigging and industrial operations, finding cost-effective rope solutions can make or break your project's budget. As someone who's been in the trenches of large-scale operations, I've learned that sourcing rope wholesale is not just about saving a few dollars - it's about optimising your entire supply chain. Let's dive into how you can leverage wholesale options to boost your bottom line while ensuring top-notch quality.

The Power of Wholesale: More Than Just Savings

When you're dealing with industrial-scale projects, every metre of rope counts. Purchasing rope wholesale isn't just about getting a better price per unit; it's about streamlining your entire procurement process. Here's why going wholesale can be a game-changer:

- Bulk discounts: The more you buy, the less you pay per unit, significantly reducing your overall costs.

- Consistent quality: Buying in bulk from a reputable supplier ensures uniformity across your rope inventory.

- Reduced lead times: With a steady supply on hand, you can kiss those project delays goodbye.

- Custom specifications: Many wholesale suppliers offer customisation options to meet your specific needs.

I remember a time when we switched to a wholesale supplier for our offshore rigging project. Not only did we save nearly 30% on our rope costs, but we also eliminated the headache of managing multiple small-batch orders. It was a revelation!

Understanding Rope Pullers and Come-Along Tools

Before we dive deeper into finding wholesale suppliers, let's take a moment to appreciate some of the unsung heroes of the rigging world: rope pullers and come-along tools. These devices are essential for any operation involving heavy lifting or tensioning.

Rope pullers, often capable of handling loads up to 1,500 lbs or 3/4 ton, are indispensable for precise control in lifting operations. Come-along tools, on the other hand, are perfect for situations requiring incremental tensioning or pulling. When sourcing these tools wholesale, consider factors like:

- Load capacity: Ensure the tools can handle your project's maximum expected load.

- Rope compatibility: Check that the puller's mechanism works well with your chosen rope type.

- Safety features: Look for tools with reliable locking mechanisms and overload protection.

Leveraging Local Wholesale Options for Industrial Rope Needs

Now, let's talk about finding those golden wholesale opportunities right in your backyard. Local suppliers can offer advantages that distant wholesalers can't match:

- Quick turnaround: Need rope urgently? A local supplier can often deliver same-day or next-day.

- Personalised service: Build a relationship with your supplier for tailored advice and support.

- Reduced shipping costs: Proximity means lower transport fees, especially for heavy bulk orders.

To find reputable local wholesale suppliers, start by:

- Checking industry directories and trade associations

- Attending local trade shows and networking events

- Asking for recommendations from other businesses in your industry

Once you've identified potential suppliers, don't be shy about asking for a facility tour. I once visited a local rope manufacturer and was impressed by their quality control processes - it sealed the deal for me. For those looking for a wide range of options, iRopes offers top-quality ropes for various applications.

Pro tip: When negotiating with wholesale suppliers, consider committing to a long-term purchasing agreement. It can often lead to even better pricing and priority service.

Remember, finding the right wholesale supplier is about more than just price. It's about building a partnership that can support your operations for years to come. By leveraging local wholesale options and understanding the intricacies of rope and rigging equipment, you're not just cutting costs - you're investing in the efficiency and reliability of your entire operation.

Have you had any experiences with local wholesale rope suppliers? I'd love to hear about them in the comments below. And if you're looking for more tips on optimising your rigging operations, stay tuned for our next post on advanced rope maintenance techniques!

```htmlQuality rigging rope is essential for the success and safety of various projects, from construction to theatre setups. Finding the right rigging materials involves understanding the different types of rope available and their specific properties. For those searching for "bulk rope near me," the focus should be on reliable sources that offer high-quality materials in various categories like nylon and polypropylene. Likewise, identifying specialised rigging rope near you requires knowledge of specific applications and usage contexts, ensuring you're equipped with ropes suited to different environments and load requirements. For cost-effective solutions, leveraging "rope wholesale near me" options can be advantageous, providing bulk purchase discounts and ensuring a steady supply of consistent-quality ropes. Prioritising the right rigging materials from trustworthy suppliers can streamline operations while maintaining top safety standards.

Contact Us to Source Your Perfect Rigging Rope Solution

For tailored advice and to purchase high-quality ropes for your projects, fill in the inquiry form above. Explore how iRopes, a leading rope manufacturer, combines innovation with the expertise needed to meet rigging demands effectively.

```