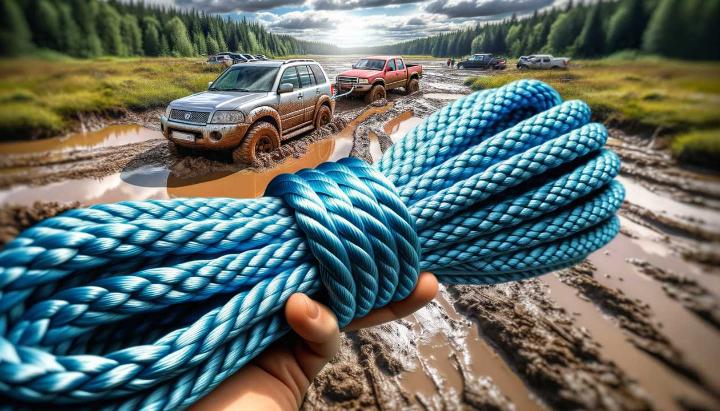

Have you ever found yourself in a precarious situation, relying on a rope that just wasn't up to the task? Picture this: you're towing a heavy load up a steep incline when suddenly, your rope snaps like a twig. It's a heart-stopping moment that no one wants to experience. That's where the unparalleled strength of braided nylon cord comes into play.

In the world of ropes and cords, braided nylon stands head and shoulders above the rest. It's not just a rope; it's a powerhouse of strength, flexibility, and safety all rolled into one. Braided nylon cord offers a unique combination of high tensile strength and remarkable elasticity, making it the go-to choice for dynamic applications like towing and heavy-duty tasks.

But what makes braided nylon rope strength so exceptional? It's not just about raw power; it's about intelligent design. The braided construction allows for even distribution of force, while the nylon fibres provide unmatched resilience and shock absorption. This means you're not just getting a strong rope; you're investing in a safety net that can handle the unexpected.

In this post, we'll dive deep into the world of braided nylon, exploring its unmatched strength, impressive elasticity, and why it's the safer choice for critical applications. Whether you're a professional in need of reliable equipment or an enthusiast looking for the best gear, understanding the power of braided nylon cord could be a game-changer for your next project. Ready to discover why this remarkable material is revolutionising the rope industry? Let's unravel the secrets of braided nylon together.

Understanding the Strength of Braided Nylon Rope

When it comes to choosing the right rope for demanding applications, understanding the strength of braided nylon is crucial. As an avid outdoorsman and longtime rope enthusiast, I've had my fair share of experiences with various materials. But time and again, I've found myself reaching for braided nylon cord when reliability is paramount.

Tensile Strength and Breaking Load of Nylon Rope

Let's dive into the nitty-gritty of what makes braided nylon rope so robust. The key lies in its impressive tensile strength, which is the maximum stress a material can withstand before breaking. For nylon, this strength is approximately 12,400 psi (pounds per square inch). To put this into perspective, a 1/2 inch double braided nylon rope boasts a staggering tensile strength of about 5,800 pounds!

But what does this mean in practical terms? Well, imagine you're securing a heavy load on a truck. The breaking strength of your rope is crucial for safety. To calculate it, we use this formula:

Breaking Strength = (Diameter in inches)2 x 12,400

For our 1/2 inch rope example, that's (0.5)2 x 12,400 = 3,100 pounds. However, always remember to factor in a safety margin. A good rule of thumb is to never load a rope beyond 20% of its breaking strength for dynamic applications.

Factors Affecting Nylon Rope Strength

Several factors contribute to the superior strength of braided nylon:

- Molecular structure: Nylon's long polymer chains interlock, providing excellent tensile strength.

- Braiding technique: The braided construction distributes load evenly, enhancing overall strength.

- Fiber quality: High-grade nylon fibers ensure consistent performance.

- Manufacturing process: Precision in production maintains the integrity of the rope structure.

It's worth noting that while nylon is incredibly strong, it's not invincible. Wet nylon fibers can lose about 15% of their strength, so always factor this in when using nylon rope in marine environments.

Comparing Braided Nylon to Other Rope Types

In my years of experience, I've found that braided nylon consistently outperforms many other rope materials. Here's a quick comparison:

- Polyester: Durable but less elastic

- Polypropylene: Floats but lower strength

- Natural fibers: Less durable, prone to rot

Braided nylon's combination of strength, elasticity, and durability makes it ideal for dynamic applications like towing, mooring, and climbing. I once used a braided nylon rope to secure a friend's stalled car during a mountain rescue. The rope's ability to absorb shock while maintaining its strength was truly impressive.

Have you ever experienced the strength of braided nylon rope firsthand? Whether you're a professional or a weekend warrior, understanding the capabilities of your equipment is crucial. Next time you're choosing a rope for a demanding task, consider the unmatched strength of braided nylon – it might just be the reliable partner you need.

Advantages of Braided Nylon Cord's Elasticity

As we delve deeper into the world of ropes, it's impossible to overlook the remarkable elasticity of braided nylon cord. This unique property sets it apart from other materials and makes it the go-to choice for a wide range of applications. Let me share with you why I've come to appreciate the elastic nature of braided nylon in my years of experience.

Superior Strength and Durability

The braiding process enhances nylon's natural strength, creating a cord that's not only robust but also incredibly resilient. I've seen braided nylon cords withstand forces that would snap other ropes in an instant. The interwoven fibres distribute stress evenly, resulting in a strength-to-weight ratio that's hard to beat.

In my time working on construction sites, I've noticed how braided nylon cords outlast their counterparts in harsh conditions. They resist abrasion, mildew, and even chemical exposure, making them a reliable choice for long-term use in various environments.

Unmatched Shock Absorption and Flexibility

The elasticity of braided nylon cord is truly remarkable. Did you know that these cords can stretch up to 20% of their length without losing strength? This flexibility is a game-changer in dynamic applications. I recall a rock climbing expedition where our braided nylon rope absorbed the shock of a sudden fall, potentially saving my climbing partner from serious injury.

The elasticity range of braided nylon cord typically falls between 15-28% at break. This means it can absorb significant energy during sudden load changes, making it ideal for towing and marine applications. The cord's ability to stretch and recover reduces the risk of sudden failure, providing an added layer of safety in critical situations.

- Shock absorption: Braided nylon's elasticity disperses energy from sudden impacts, reducing stress on attachment points.

- Load distribution: The cord's flexibility allows for even distribution of force across its length, preventing weak spots.

- Vibration dampening: In industrial settings, the elastic properties help reduce harmful vibrations in machinery.

Have you ever experienced the difference between a rigid rope and an elastic one in a high-stress situation? The contrast is night and day. Braided nylon's elasticity not only enhances safety but also improves the overall performance of the system it's part of.

In my next boating trip, I'm planning to replace my old mooring lines with braided nylon cord. The thought of its superior shock absorption capabilities gives me peace of mind, knowing it will help protect my vessel from sudden jerks and movements caused by waves or wind.

As we continue to explore the advantages of braided nylon cord, remember that its elasticity is not just a feature – it's a crucial factor that could make all the difference in your next project or adventure. Have you considered how braided nylon's elasticity could benefit your specific application? For more information on maximizing rope strength, you might want to read up on optimizing nylon and wire ropes.

Braided Nylon Cord: The Safer Choice

When it comes to selecting the right cord for critical applications, safety should always be your top priority. That's where braided nylon cord truly shines. As someone who's spent years working with various rope materials, I can confidently say that braided nylon is the safer choice for a wide range of uses.

Reduced Risk of Sudden Failure

One of the most impressive features of braided nylon cord is its ability to withstand sudden stress without failing. This is due to its unique combination of strength and elasticity. I remember a time when I was helping a friend tow his boat, and we hit an unexpected bump. The braided nylon tow rope stretched slightly, absorbing the shock and preventing any damage to both vehicles.

- Excellent load distribution: The braided construction allows for even distribution of force, reducing weak points.

- High tensile strength: Braided nylon can handle significant loads without breaking.

- Controlled elongation: The cord stretches under load, absorbing shock and reducing the risk of sudden snaps.

Resistance to Environmental Factors

Another reason why braided nylon cord is a safer choice is its impressive resistance to various environmental factors. Unlike some other materials, nylon holds up well against abrasion, UV radiation, and many chemicals. This durability ensures that the cord remains safe and reliable even after extended use in challenging conditions.

During a camping trip last summer, I noticed how well my braided nylon guy lines had held up after years of use. Despite exposure to sun, rain, and constant tension, they showed minimal signs of wear. This level of durability is crucial when you're relying on your equipment in potentially dangerous situations.

Meeting Safety Standards

When selecting cord for critical applications, it's essential to choose products that meet or exceed safety standards. While the EPA Safer Choice program primarily focuses on chemicals and cleaning products, its principles of safety and environmental responsibility can be applied to cord selection as well.

High-quality braided nylon cords often meet stringent safety standards set by various industries. For instance, in marine applications, many braided nylon ropes comply with standards set by organisations like the International Maritime Organization (IMO).

Always check the manufacturer's specifications and certifications when selecting braided nylon cord for critical applications. This ensures you're using a product that meets the necessary safety standards for your specific use case. Consider exploring marine rope clamps and safety guidelines to enhance your understanding of secure operations.

In conclusion, braided nylon cord's combination of strength, elasticity, and durability makes it a safer choice for a wide range of applications. Whether you're securing heavy loads, setting up camp, or working in challenging environments, choosing high-quality braided nylon cord can provide peace of mind and enhanced safety. Remember, when it comes to critical applications, investing in the right materials is always worth it.

Versatility of Braided Nylon Rope

As a seasoned rope enthusiast, I've come to appreciate the incredible versatility of braided nylon rope. Its unique combination of strength, durability, and flexibility makes it a go-to choice for countless applications across various industries. Let me share with you why this remarkable material has become indispensable in so many fields.

Advantages of Nylon Rope

Braided nylon rope boasts a set of characteristics that set it apart from other materials:

- Superior strength-to-weight ratio: Pound for pound, braided nylon outperforms many other rope materials, making it ideal for heavy-duty applications.

- Excellent stretch and recovery: The natural elasticity of nylon allows the rope to absorb shock loads, reducing the risk of sudden failure.

- Impressive durability: Resistant to abrasion, UV rays, and many chemicals, braided nylon rope maintains its integrity even in harsh environments.

- Water-resistant properties: While nylon can absorb some moisture, it remains strong and functional even when wet, unlike some natural fibre ropes.

I once used a braided nylon rope to secure equipment on a week-long sailing trip. Despite constant exposure to saltwater and sun, the rope performed flawlessly, showing minimal wear by the end of the journey. This experience really drove home the exceptional durability of this material.

Applications of Braided Nylon Rope

The versatility of braided nylon rope is truly remarkable. Here are just a few examples of its wide-ranging applications:

- Marine uses: From mooring lines to anchor rodes, braided nylon's strength and shock-absorbing properties make it perfect for nautical applications.

- Construction and industry: Used in pulley systems, winches, and for securing heavy loads, the rope's high tensile strength is invaluable.

- Outdoor activities: Climbers, campers, and hikers rely on braided nylon for its durability and lightweight nature.

- Agriculture: Farmers use it for everything from towing to animal handling, appreciating its strength and resistance to rot.

- Safety and rescue operations: The rope's reliability makes it a top choice for life-saving equipment and rescue scenarios.

In my experience working with search and rescue teams, we always opted for braided nylon ropes. Their dependability in critical situations, combined with their ability to absorb sudden loads, made them the safest choice for both rescuers and those being rescued.

The versatility of braided nylon rope extends to its availability in various sizes and configurations. Whether you need a thin cord for delicate work or a thick rope for heavy-duty applications, there's likely a braided nylon option that fits the bill. This adaptability is one of the reasons I always keep a selection of braided nylon ropes in my toolkit – you never know when you might need them! If you're interested, you can learn more about the ultimate versatility of ropes in various scenarios.

When selecting braided nylon rope for your specific needs, always consider factors such as required strength, expected load, environmental conditions, and any relevant safety standards. Consulting with a rope specialist can help ensure you choose the right product for your application.

Have you ever used braided nylon rope in an unexpected way? Its versatility often leads to creative problem-solving in the field. Whether you're a professional contractor, an outdoor enthusiast, or simply someone who appreciates quality tools, braided nylon rope is a versatile addition to any toolkit. Next time you're faced with a challenging rigging or securing task, consider the unmatched versatility of braided nylon – it might just be the perfect solution you've been looking for.

Discover the Benefits of Braided Nylon Cord for Towing and Dynamic Applications

When choosing the right rope for towing and dynamic applications, consider the unmatched strength and versatility of braided nylon cord. Known for its high tensile strength, braided nylon rope delivers exceptional break loads, making it a reliable choice for demanding tasks. Its elasticity provides excellent shock absorption and reduces the risk of sudden failures, enhancing safety significantly. Besides strength and elasticity, braided nylon is resistant to abrasion, UV radiation, and chemicals, ensuring long-lasting performance. Whether used for towing vehicles, in marine settings, or critical applications, the braided nylon cord is the superior choice due to its robust strength and flexibility. Fill in the form above to learn more about the benefits of braided nylon and find the best fit for your needs.