Imagine a world where strength meets versatility, where the perfect rope solution not only outperforms but also outshines the competition. Welcome to the realm of 2 and 1.5 nylon rope solutions, where cutting-edge technology intersects with unparalleled customization.

At iRopes, we understand that every application demands precision, and that's why we've mastered the art of crafting nylon ropes with unrivaled strength, durability, and flexibility. Our 2 nylon rope solutions are the epitome of resilience, designed to withstand the most demanding environments while ensuring maximum safety and reliability.

But what truly sets us apart is our commitment to innovation. Our 1.5 nylon rope offerings strike the perfect balance between strength and versatility, making them the go-to choice for a wide range of industries and applications. From securing heavy loads to navigating the rugged outdoors, these ropes are engineered to adapt to your unique needs, seamlessly integrating into your workflow.

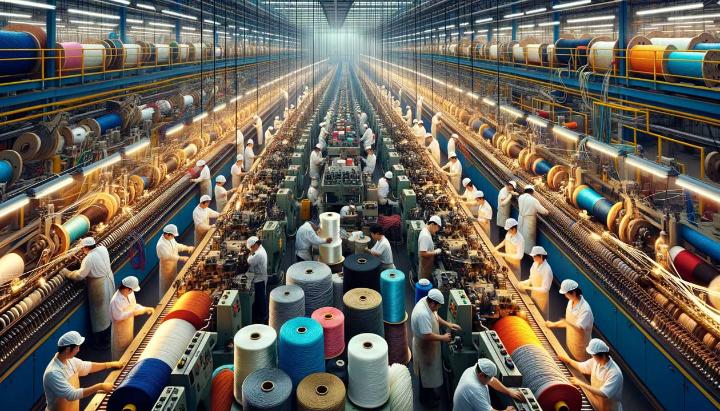

At the heart of our success lies our dedication to using only the highest-quality industrial nylon filaments, masterfully woven into ropes that defy expectations. Whether you're a seasoned professional or an adventure enthusiast, our nylon rope solutions are poised to elevate your game, redefining what's possible in terms of performance and customization.

• iRopes’ coating cover on the whole rope,very good abrasion. Longer use life extra

with 100mm length black rubber cover until thread wrap part PU different color

Coating very good abrasion.avaliable in different eye colour .

MATERIAL: Nylon core Nylon cover

CONSTRUCT: double braided

ELONGATION: 30%

Understanding Nylon Rope Strength

When it comes to selecting the right rope for your needs, understanding nylon rope strength is crucial. Have you ever wondered why some ropes can withstand heavier loads than others? The secret lies in the high-quality industrial nylon filaments used in their production.

Factors Affecting Nylon Rope Strength

- Diameter and Construction The thicker the nylon rope, the higher its breaking strength. But it's not just about diameter; the way the rope is constructed – braided, twisted, or with a parallel core – also impacts its overall strength.

- Environmental Conditions Abrasion, UV exposure, and chemical exposure can weaken nylon ropes over time. Even water absorption can potentially reduce their strength, so it's essential to use them correctly and store them properly.

Calculating Nylon Rope Breaking Strength

To determine a nylon rope's breaking strength, manufacturers typically use a formula based on the rope's diameter. But remember, the breaking strength is not the same as the safe working load – you'll need to apply a safety factor to account for potential wear and tear.

For example, a 1/2-inch nylon rope may have a breaking strength of 8,000 pounds. With a safety factor of 5, its safe working load would be 1,600 pounds. Always follow the manufacturer's guidelines to ensure safe usage and avoid overloading the rope.

Compared to other materials like polyester or manila, nylon ropes offer superior strength and flexibility, making them an excellent choice for a wide range of applications. By understanding the factors that contribute to nylon rope strength, you can make an informed decision and select the right rope for your specific needs.

Durability and Resilience of 2 Nylon Rope

When it comes to demanding applications, nylon ropes are a cut above the rest. Their exceptional durability and resilience make them the go-to choice for professionals who value reliability and longevity. But what sets 2 nylon rope apart? Let's unravel its remarkable properties.

Nylon Rope Strength and Breaking Point

Nylon ropes are renowned for their incredible tensile strength, consistently outperforming other materials like manila or polypropylene. This strength stems from the high-quality industrial nylon filaments used in their construction. But it's not just about raw strength – nylon ropes also boast impressive breaking strengths. For instance, a 1/2-inch double-braided nylon rope can have a breaking strength of up to 8,000 pounds!

However, it's crucial to understand the difference between breaking strength and safe working load. The safe working load takes into account potential wear and tear, typically calculated by applying a safety factor to the breaking strength. For example, with a safety factor of 5, that same 1/2-inch nylon rope would have a safe working load of 1,600 pounds. Always follow manufacturer guidelines to ensure safe and appropriate usage.

Abrasion Resistance and Longevity of Nylon Ropes

One of the standout features of 2 nylon rope is its remarkable abrasion resistance. Unlike other materials that can quickly wear down under friction, nylon ropes can withstand intense abrasion while maintaining their structural integrity. This abrasion resistance not only enhances the rope's lifespan but also ensures consistent performance in demanding environments.

Moreover, nylon ropes are highly resistant to UV exposure, weathering, and most chemicals. This resilience means they can be used outdoors without worrying about premature degradation or brittleness. With proper care and storage, a high-quality 2 nylon rope can provide years of reliable service, even under challenging conditions.

To maximize the longevity of your nylon ropes, follow these best practices:

- Proper handling and storage Avoid excessive bending, kinking, or exposure to harsh chemicals.

- Regular inspections Routinely check for signs of wear, damage, or deterioration.

- Adherence to manufacturer guidelines Follow recommended usage, load limits, and maintenance instructions.

Factors Affecting Nylon Rope Resilience

While nylon ropes are undoubtedly durable, their resilience can be compromised by various factors. Improper use, such as exposing the rope to excessive shock loading or sudden jerks, can cause internal damage and weaken its overall strength. Environmental conditions like extreme temperatures, chemical exposure, or prolonged UV radiation can also take a toll on the rope's integrity.

To ensure optimal resilience, it's essential to follow manufacturer guidelines and safety protocols. Regular inspections and maintenance are crucial to identifying potential issues before they escalate. Remember, a compromised nylon rope not only poses a safety risk but can also lead to costly downtime and replacements. For a more detailed exploration of rope materials, check out our article on the benefits of Nylon and Dyneema cordage.

In high-risk industries like construction or mining, the consequences of rope failure can be catastrophic. That's why it's crucial to prioritize rope resilience and never compromise on quality or proper usage.

Always follow manufacturer guidelines and safety protocols to ensure the resilience and longevity of your nylon ropes. Regular inspections and proper maintenance are essential for safe and reliable performance.

Versatility of 1.5 Nylon Rope

When it comes to nylon rope, the 1.5 diameter is particularly versatile – balancing strength, durability, and flexibility. This makes it an ideal choice for numerous applications, as we'll explore in this section.

Strength and Durability of Nylon Ropes

Nylon ropes are known for their robust tensile strength, and the 1.5 diameter is no exception. These ropes can withstand substantial stress and strain, making them suitable for more demanding applications, whether it's securing a heavy load or bracing against tension.

At the same time, this diameter offers impressive durability. The braided nylon fibers resist abrasion and wear, ensuring a longer lifespan compared to many smaller diameter ropes. This durability makes 1.5 nylon ropes a cost-effective choice, as you won't need to replace them as frequently. For additional details on the durability and applications of twisted rope, visit our guide on the advantages of twisted rope.

Flexibility and Ease of Use

Despite their strength, 1.5 nylon ropes remain relatively lightweight and flexible compared to larger diameters. This versatility allows for a wide range of applications, from securing loads and creating lifting points to fashioning slip-proof knots that won't easily unravel.

The flexibility of 1.5 nylon rope also makes it easier to handle and manipulate. You can tie more intricate knots or weave more complex patterns with this diameter, unlike thicker ropes that can be unwieldy.

For example, a rock climber might prefer a 1.5 nylon rope for its combination of strength (to support their weight) and flexibility (to tie reliable knots). Similarly, a sailor could choose this diameter for its ability to withstand the elements while remaining easy to work with on deck.

Cost-Effectiveness and Value

In addition to its versatility, 1.5 nylon rope offers excellent value. While not as thick and heavy-duty as larger diameters, it still provides ample strength for most applications at a lower cost. This balance makes it a cost-effective choice for projects with budget constraints.

Furthermore, as we've seen, the durability of nylon rope means a longer lifespan compared to other materials. You get more bang for your buck, with the potential to use the same length of rope for an extended period across various projects. Learn more about iRopes' cost-effective and versatile solutions in our guide on premium quality ropes for every industry.

All in all, the strength, versatility, and cost-effectiveness of 1.5 nylon rope make it a wise choice for those seeking a high-performance, reliable rope solution without the premium price tag.

With all these factors in mind, let's now explore one of the key applications where 1.5 nylon rope truly shines.

Custom Nylon Rope Solutions: Tailored Possibilities

In today's fast-paced world, where efficiency and brand recognition are paramount, having the right tools tailored to your specific needs can make all the difference. That's where custom nylon rope solutions come into play. Imagine having a rope that not only meets your performance requirements but also reflects your unique brand identity – a true game-changer!

At iRopes, we understand that one size doesn't fit all. That's why we offer a wide range of customization options, empowering you to create the perfect nylon rope solution for your unique application. Whether you're an outdoor enthusiast, an industrial professional, or a boat captain, our team of experts is here to bring your vision to life.

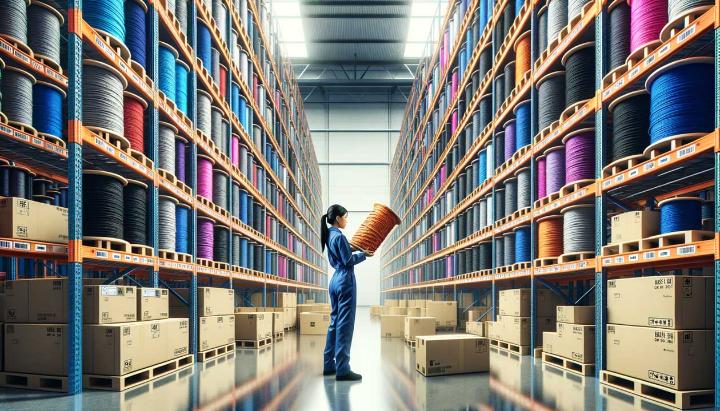

Customizable Lengths and Packaging

Let's start with the basics – length and packaging. We know that having the right length of rope is crucial for seamless operations. Too short, and you'll struggle to complete your task. Too long, and you'll end up with excess material and potential safety hazards. That's why we offer customizable lengths to ensure a precise fit for your needs.

But we don't stop there. We also provide a variety of packaging options to suit your preferences. Need a compact spool for easy storage and transportation? No problem. Prefer a coiled option for quick deployment? We've got you covered. Or perhaps you'd like custom labeling for effortless identification and organization? Just let us know, and we'll make it happen.

Bespoke Colors, Patterns, and Branding

Now, let's talk about the fun part – customizing the look and feel of your nylon rope. Imagine having a rope that not only performs flawlessly but also reflects your brand's unique identity. With our bespoke color and pattern options, the possibilities are endless.

From vibrant hues that complement your company's logo to intricate patterns that make a bold statement, we can create a truly one-of-a-kind nylon rope that sets you apart from the competition. And if you really want to take your branding game to the next level, we offer direct logo printing or embossing services, ensuring your company's name or logo is prominently displayed on every inch of the rope.

But why stop at aesthetics? Custom branding can also serve a functional purpose. For instance, if you work in a high-risk environment where visual identification is crucial, a brightly colored or patterned rope can enhance safety and visibility, helping to prevent accidents and ensure smooth operations.

At iRopes, we believe that customization is the key to unlocking your full potential. Let us help you create a nylon rope solution that not only meets your performance needs but also reflects your brand's unique identity.

So, whether you're an adventure seeker, a construction professional, or a brand-conscious business owner, custom nylon rope solutions from iRopes can elevate your experience and set you apart from the crowd. Embrace the possibilities and let us craft the perfect rope solution tailored to your unique needs.

Explore Our Custom Nylon Rope Solutions

Discover the unbeatable strength and versatility of iRopes' 2 nylon rope and 1.5 nylon rope solutions, designed with high-strength industrial nylon filaments. Our ropes offer exceptional durability, abrasion resistance, and UV protection, making them ideal for demanding applications. The 2 nylon rope excels in resilience and long-lasting performance, while the 1.5 nylon rope provides flexibility and cost-effectiveness, perfect for various industries. With customisation options, including specific lengths, colours, and branded packaging, iRopes' nylon rope solutions are tailored to meet your unique requirements. Fill in the form above to explore how our nylon ropes can elevate your operations.