Did you know that the difference between a successful project and a potential disaster often comes down to the quality of your rope? In the world of industrial and recreational applications, two types of rope solutions stand out: latex bungee cord and flat hollow braid rope. While many consider these merely functional items, they're actually engineering marvels that can make or break your operations.

At iRopes, we've revolutionised the approach to creating high-performance rope solutions. Whether you're considering crafting your own homemade bungee cord for customised applications or seeking professional-grade flat hollow braid rope for industrial use, understanding the nuances of these products is crucial for making informed decisions.

In this comprehensive guide, we'll explore the fascinating world of rope manufacturing, sharing our expertise gained from years of serving global markets with premium-quality rope solutions. From the precise engineering behind latex bungee cords to the innovative construction of flat hollow braid ropes, we'll reveal how these versatile products can enhance your operations while potentially reducing costs and improving efficiency.

Understanding Latex Bungee Cord and its Applications

Have you ever wondered what gives bungee cords their remarkable stretching ability? At the heart of every quality bungee cord lies natural latex rubber, a material that's revolutionized the way we secure and transport items.

What is Latex Bungee Cord?

A latex bungee cord combines the exceptional elasticity of natural latex rubber with a protective braided outer sheath. The core consists of multiple strands of latex rubber working together to provide consistent stretch and reliable snap-back properties. This ingenious construction allows the cord to extend up to 120% of its original length while maintaining its structural integrity.

Key Features and Benefits

- Superior Elasticity - Natural latex provides unmatched stretch and recovery capabilities compared to synthetic alternatives

- Durability - Double-braided outer cover protects the core from UV damage and abrasion

- Weather Resistance - Maintains performance across various temperature ranges and weather conditions

- Customizable Strength - Available in different diameters and configurations to match specific load requirements

Common Applications

The versatility of latex bungee cords makes them indispensable across numerous industries and applications. From securing cargo on trucks to organizing equipment in workshops, these elastic workhorses prove their worth daily. In marine environments, they're particularly valuable for their corrosion resistance and ability to absorb shock loads.

When selecting a latex bungee cord, always choose one rated for at least 50% more than your intended load to ensure safety and longevity.

Whether you're looking for reliable cargo security or need flexible equipment mounting solutions, understanding the properties and capabilities of latex bungee cords helps you make informed decisions for your specific needs.

Exploring the Benefits of Homemade Bungee Cord

After understanding the fundamentals of latex bungee cords, let's explore why creating your own can be both rewarding and practical. DIY enthusiasts and professionals alike are discovering the advantages of crafting custom bungee solutions tailored to their specific needs.

Cost-Effective DIY Solutions

Creating your own bungee cords can lead to significant cost savings, especially when you need multiple cords or specific lengths. By purchasing materials in bulk and assembling them yourself, you can reduce expenses while maintaining high quality standards. To explore more about crafting bungee solutions, check out our guide on synthetic winch rope for off-road use.

- Material Cost Savings - Bulk natural latex rubber and braided sheathing materials often cost less than pre-made cords

- Length Optimization - Create exactly the sizes you need without waste or excess inventory

- Quantity Control - Produce the exact number of cords required for your project

Customization Options

One of the most compelling reasons to make your own bungee cords is the ability to customize every aspect of their construction. Whether you need specific strength ratings or unique configurations, DIY allows for complete control over:

- Strength Specifications - Select latex core thickness and strand count for precise load capacity

- Color Coding - Use different colored sheaths to identify various strength ratings or applications

- End Fittings - Choose from various hook styles or create custom terminations

Quality Control in Production

When making your own bungee cords, you have direct oversight of the entire manufacturing process. This control allows you to ensure each component meets your standards and specifications. Discover essential practices for ensuring quality by exploring our premium rope solutions at iRopes.

Always perform thorough testing of your homemade bungee cords before putting them into service. Start with loads at 50% of your intended capacity and gradually increase while monitoring for any signs of weakness.

- Material Selection - Choose premium-grade latex rubber and durable braided coverings

- Assembly Inspection - Carefully monitor each step of the construction process

- Testing Protocols - Implement rigorous testing procedures to ensure safety and reliability

Creating your own bungee cords isn't just about saving money - it's about crafting purpose-built solutions that perfectly match your requirements while maintaining complete control over quality and specifications.

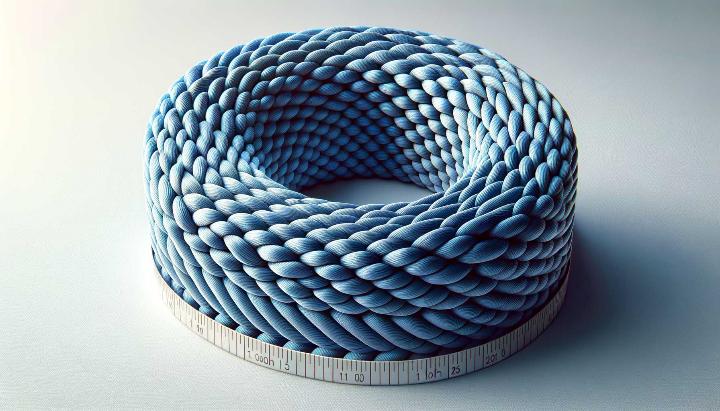

Discovering the Versatility of Flat Hollow Braid Rope

Now that we've explored the world of bungee cords, let's dive into another fascinating rope construction that's revolutionizing various industries. Have you ever wondered why some ropes feel surprisingly light yet maintain impressive strength? The secret lies in the innovative flat hollow braid design.

Understanding Flat Hollow Braid Rope Construction

Unlike traditional ropes with a solid core, flat hollow braid rope features a unique construction using 8 to 16 interwoven strands that create a tubular shape. This coreless design isn't just clever engineering - it's a game-changer for numerous applications where flexibility and strength are paramount.

Key Features and Benefits

- Superior Flexibility - The hollow construction allows for exceptional bend radius without compromising strength

- Easy Splicing - Hollow design enables quick and secure splice connections without special tools

- Natural Buoyancy - Perfect for marine applications due to its floating capabilities

- Lightweight Strength - Achieves impressive strength-to-weight ratios through innovative strand patterns

Did you know? The hollow construction allows for custom strength modifications by inserting additional strands or cores when needed, making it incredibly versatile for specific applications.

Applications Across Industries

The versatility of flat hollow braid rope makes it invaluable across numerous sectors. In marine applications, it excels as dock lines and anchor rodes thanks to its buoyancy and resistance to UV damage. Industrial users appreciate its ease of handling and splicing capabilities for rigging and utility applications. To learn more about rope applications in marine settings, read our guide on marine rope specifications and uses.

- Marine Uses - Ideal for mooring lines, dock lines, and anchor rodes

- Industrial Applications - Perfect for utility pulls, rigging, and general purpose use

- Recreational Activities - Popular in camping, climbing, and outdoor adventures

At iRopes, we specialize in crafting premium flat hollow braid rope using advanced synthetic materials like polyester and polypropylene. Our manufacturing process ensures consistent quality across every meter, delivering the perfect balance of strength, flexibility, and durability that our customers depend on.

iRopes' Commitment to Excellence in Rope Manufacturing

At the heart of every exceptional rope lies a commitment to manufacturing excellence that goes beyond ordinary standards. Have you ever wondered what makes some ropes stand out in terms of strength, durability, and performance? The answer lies in the careful selection of materials and advanced manufacturing processes.

Superior Quality Standards and Materials

In our pursuit of excellence, we've embraced the most advanced synthetic fibers available in rope manufacturing today. Each material is chosen for its unique properties and specific performance characteristics.

- UHMWPE (Ultra-High-Molecular-Weight Polyethylene) - Provides exceptional strength-to-weight ratio and superior UV resistance

- Technora™ - Delivers outstanding heat resistance and dimensional stability

- Kevlar™ - Offers unmatched tensile strength and cut resistance

- Vectran™ - Ensures zero creep and excellent flex fatigue resistance

- Polyamide and Polyester - Provides versatility and cost-effectiveness for general applications

Innovative Coating Technologies

Our commitment to quality extends beyond fiber selection to include advanced coating technologies that enhance rope performance and longevity. Each coating is precisely applied to match specific application requirements.

Did you know? Our proprietary coating processes can extend rope life by up to 40% in harsh environmental conditions while maintaining optimal handling characteristics.

- Marine-Grade Protection - Specialized coatings that resist salt water and UV degradation

- Anti-Abrasion Finish - Enhanced surface protection for high-wear applications

- Temperature-Resistant Treatment - Coatings designed for extreme temperature environments

Made in China, Perfected Through Excellence

We take pride in showcasing how Chinese manufacturing has evolved to meet and exceed global quality standards. Our state-of-the-art facilities combine traditional rope-making expertise with modern technology to deliver products that consistently surpass industry expectations.

- ISO 9001 Certification - Rigorous quality management systems ensure consistent product excellence

- Advanced Testing Laboratory - Every batch undergoes comprehensive testing for strength and durability

- International Standards Compliance - Products meet or exceed global industry specifications

When you choose iRopes, you're not just selecting a rope manufacturer - you're partnering with a team dedicated to pushing the boundaries of what's possible in rope technology. Our commitment to excellence ensures that every rope we produce represents the pinnacle of manufacturing quality and innovation.

```htmlExplore the dynamic world of rope manufacturing with iRopes. Our expertise in latex bungee cord production delivers superior elasticity, durability, and weather resistance—perfect for various applications. Discover the cost-saving benefits of homemade bungee cord that offer ultimate customization and quality control. Meanwhile, the flat hollow braid rope is revolutionizing industries with its flexibility, strength, and buoyancy, ideal for marine and industrial use. iRopes crafts these ropes using cutting-edge synthetic fibers like UHMWPE and Kevlar™, ensuring the excellence of "Made in China" products. For those seeking top-tier rope solutions, contact us to explore our extensive range of applications and customization options.

Contact iRopes for Your Custom Rope Solutions

If you're intrigued by the potential of latex bungee cord, homemade bungee cord techniques, or the versatility of flat hollow braid rope, our experts are ready to assist. The form above is your gateway to detailed insights and tailored solutions that align with your specific needs. Reach out to iRopes and discover how our high-quality, custom rope products can elevate your operations.

```