Picture this: you're standing at the base of a towering construction site, watching as a massive steel beam dangles precariously from a crane. The success of your entire project hinges on one crucial element - the strength of the rope supporting that load. Have you ever wondered what makes the difference between a smooth lift and a catastrophic failure?

Enter the world of UHMWPE slings - the unsung heroes of heavy lifting. These aren't your grandfather's ropes; they're the cutting-edge solution that's revolutionising the industry. But what makes them so special? And why should you care?

At iRopes, we've made it our mission to answer these questions and more. As a leading rope maker in China, we're not just selling products; we're offering a lifeline to safety, efficiency, and innovation in the world of heavy lifting. From our state-of-the-art UHMWPE slings to our custom-tailored solutions, we're changing the game one lift at a time.

In this post, we'll dive deep into the world of heavy lifting ropes, exploring why the best rope for lifting load matters more than you might think. We'll uncover the secrets behind our iropes UHMWPE sling and show you how the right sling for lifting load can transform your operations. Whether you're a seasoned professional or new to the world of rigging, get ready to discover why the rope for heavy lifting you choose could be the most important decision you make today.

Understanding the Best Ropes for Heavy Lifting

When it comes to heavy lifting, choosing the right rope can make all the difference between a successful operation and a potentially dangerous situation. As someone who's spent years in the rigging industry, I've seen firsthand how crucial it is to select the perfect rope for each unique lifting task.

Types of Ropes for Lifting Heavy Loads

Let's dive into the world of lifting ropes, shall we? Imagine you're standing in a warehouse, surrounded by different types of ropes, each with its own unique properties and applications. It's like being a kid in a candy store, but instead of sweets, you're choosing the backbone of your lifting operations.

- Synthetic ropes are the rising stars in the lifting world. They're lightweight yet incredibly strong, making them a favourite for many modern lifting applications.

- Wire ropes are the old reliable workhorses. You'll often see these sturdy cables doing the heavy lifting on construction sites and in industrial settings.

- Natural fibre ropes still have their place, but they're less common in heavy lifting due to their lower strength-to-weight ratio.

Key Factors in Choosing Lifting Ropes

Now, let's talk about what really matters when you're selecting a rope for heavy lifting. It's not just about picking the strongest rope you can find - there's a bit of science and a lot of practicality involved.

Safety First!

Always prioritise safety when choosing a lifting rope. Your choice could be the difference between a smooth operation and a workplace incident.

Here are some crucial factors to consider:

- Load capacity is paramount. You need to know exactly how much weight your rope can safely handle.

- Environmental conditions play a big role. Is your rope going to be exposed to harsh chemicals, extreme temperatures, or UV radiation?

- Rope diameter and length need to be just right for your specific application.

- Flexibility and handling are important for ease of use and storage.

Remember, there's no one-size-fits-all solution when it comes to lifting ropes. Each situation demands careful consideration of these factors to ensure you're using the best tool for the job.

Have you ever wondered why some ropes feel smooth while others have a rough texture? It's all about the materials and construction methods used. For instance, nylon ropes have a high tensile strength and excellent shock absorption, making them ideal for dynamic loads. On the other hand, polyester ropes offer great resistance to UV degradation and chemicals, perfect for outdoor use.

As we wrap up this section, I want you to think about the lifting tasks you typically encounter. What type of rope would best suit your needs? In the next section, we'll explore how iRopes' UHMWPE slings are revolutionising the lifting industry with their superior strength-to-weight ratio and durability. Stay tuned!

UHMWPE Slings: A Superior Choice for Heavy-Duty Lifting

When it comes to heavy-duty lifting, the choice of sling material can make or break your operation. As someone who's spent years in the rigging industry, I've seen firsthand how the right sling can revolutionise a worksite. That's why I'm excited to introduce you to UHMWPE slings - the unsung heroes of modern lifting operations.

Advantages of UHMWPE Slings Over Traditional Materials

UHMWPE, or Ultra-High-Molecular-Weight Polyethylene, is a game-changer in the world of lifting slings. You might know it by its brand name, Dyneema®. Let me paint a picture for you: imagine a material as light as a feather but strong enough to lift a car. That's UHMWPE in a nutshell.

- Unmatched strength-to-weight ratio: UHMWPE slings can lift loads up to 15 times their own weight, outperforming steel wire ropes by a long shot.

- Chemical and abrasion resistance: These slings laugh in the face of harsh chemicals and rough surfaces that would quickly wear down traditional materials.

- Flexibility and ease of handling: Ever tried to wrestle with a stiff wire rope? UHMWPE slings are as flexible as a gymnast, making them a joy to work with.

- Enhanced safety: Their lightweight nature reduces the risk of back injuries and makes them safer to handle in high places.

Applications and Industries for UHMWPE Lifting Slings

You might be wondering, "Where can I use these wonder slings?" The answer is: almost anywhere! From the depths of the ocean to the heights of construction sites, UHMWPE slings are making waves across industries.

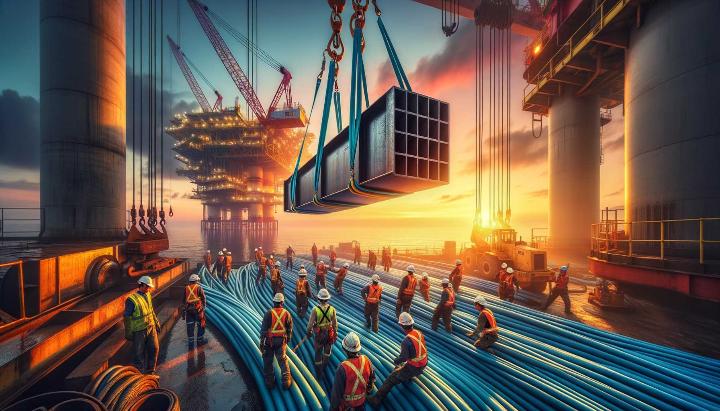

- Offshore operations: Their corrosion resistance and high strength make them perfect for marine environments.

- Construction: Lightweight yet powerful, they're ideal for lifting heavy building materials.

- Manufacturing: Their precision and gentle handling protect delicate machinery during transport.

Let me share a quick story. Last year, I worked on a project where we needed to lift a sensitive piece of equipment worth millions. The client was nervous about potential damage. We used UHMWPE slings, and not only did they handle the weight with ease, but their soft touch ensured not a scratch on the equipment. The look of relief on the client's face was priceless!

Now, you might be thinking, "This sounds great, but where can I get my hands on these slings?" That's where iRopes comes in. As a leading rope maker in China, we've mastered the art of creating UHMWPE slings that meet and exceed industry standards. Our commitment to quality means you're not just getting a sling; you're getting peace of mind.

Have you ever considered how the right lifting equipment could transform your operations? Whether you're looking to improve safety, efficiency, or just stay ahead of the curve, UHMWPE slings might be the solution you've been searching for. Why not give them a try and experience the difference for yourself?

Customization Options for Heavy Lifting Ropes

When it comes to heavy lifting, one size definitely doesn't fit all. That's where customization comes into play. As someone who's spent years working with various lifting applications, I can tell you that the right customization can make all the difference in safety, efficiency, and overall performance.

Types of Rope Materials for Heavy Lifting

Let's dive into the world of rope materials. It's like choosing the perfect ingredients for a recipe - each material brings its own unique flavour to the mix.

- Dyneema (UHMWPE) is the superhero of lifting ropes. It's incredibly strong yet lightweight, making it perfect for those jobs where every gram counts.

- Polyester is your reliable workhorse. It's resistant to stretching and offers excellent wear resistance, ideal for repetitive lifting tasks.

- Nylon brings flexibility to the table. Its ability to absorb shock makes it great for dynamic lifting scenarios.

Tailoring Rope Specifications for Specific Lifting Needs

Now, let's talk about tailoring your rope. It's like getting a bespoke suit - every detail matters.

- Length and diameter are crucial. Too short, and you're in trouble. Too long, and you're wasting material and potentially compromising safety.

- Coatings can be a game-changer. They can enhance UV resistance, improve abrasion resistance, or even make your rope glow in the dark for those night operations.

- End fittings and splicing options are the unsung heroes. The right termination can make your rope easier to use and significantly improve its lifespan.

I remember a project where we needed a rope for an offshore lifting operation. We chose a Dyneema rope with a special UV-resistant coating and custom spliced ends. The client was amazed at how much easier and safer their operations became.

Did you know? The right customization can increase your rope's lifespan by up to 50%, saving you money in the long run.

At iRopes, we're passionate about creating custom rope solutions. Whether you need a heavy-duty synthetic fiber rope for a construction project or a specialised lifting sling for precision manufacturing, we've got you covered. Our team of experts can guide you through the customization process, ensuring you get a rope that's perfectly tailored to your specific lifting needs.

Remember, the right rope isn't just about strength - it's about finding the perfect balance of properties for your unique application. So, what custom features would make your lifting operations safer and more efficient? Let's explore the possibilities together.

Partnering with iRopes for Your Lifting Sling Solutions

When it comes to heavy-duty rigging and lifting operations, choosing the right partner can make all the difference. That's where iRopes comes in. As a leading rope maker in China, we've been at the forefront of lifting sling technology for years, consistently delivering high-quality products that meet and exceed industry standards.

Benefits of Choosing iRopes Lifting Slings

What sets iRopes apart in the world of lifting slings? Let me paint you a picture. Imagine a sling so strong it can lift the weight of a small car, yet so light you can easily coil it with one hand. That's the power of our UHMWPE slings.

- Unmatched strength-to-weight ratio: Our Dyneema fiber slings offer superior lifting capacity while being incredibly lightweight, reducing the risk of workplace injuries.

- Enhanced safety features: Every iRopes sling undergoes rigorous testing to ensure it meets or exceeds safety regulations and industry standards.

- Durability that saves you money: The exceptional wear resistance of our slings means fewer replacements and lower long-term costs for your operations.

- Versatility across industries: From construction to offshore operations, our slings are designed to perform in diverse environments and applications.

Custom Lifting Sling Solutions for Your Industry

At iRopes, we understand that every lifting challenge is unique. That's why we don't just offer off-the-shelf solutions; we work closely with you to create tailored lifting slings that meet your specific needs.

Let me share a recent experience. We had a client in the offshore wind industry who needed a sling that could withstand harsh marine conditions while maintaining its strength. Our team developed a custom UHMWPE sling with a special UV-resistant coating. The result? A sling that not only met their lifting requirements but also significantly outlasted their previous solutions.

- Industry-specific customization: Whether you're in aerospace, marine, or mining, we can create slings tailored to your unique challenges.

- Innovative coating options: From UV protection to enhanced abrasion resistance, our coatings can add extra layers of performance to your slings.

- Precision engineering: Our state-of-the-art facilities allow us to manufacture slings to exact specifications, ensuring a perfect fit for your equipment.

Did you know? iRopes can create custom lifting slings with load capacities ranging from 1 ton to over 1000 tons, catering to a wide array of lifting needs.

Are you ready to revolutionize your lifting operations? At iRopes, we're not just selling slings; we're offering a partnership built on expertise, innovation, and a commitment to your success. Whether you need a standard UHMWPE sling or a highly specialized lifting solution, we're here to help.

Don't let subpar lifting equipment hold your operations back. Contact iRopes today, and let's discuss how we can create the perfect lifting sling for your unique needs. Remember, in the world of heavy lifting, the right sling isn't just equipment – it's your lifeline to safety and efficiency.

Choosing the best rope for lifting heavy loads is crucial, and iRopes' UHMWPE sling is an exceptional option due to its superior strength-to-weight ratio and durability. iRopes, a leading rope manufacturer in China, specialises in creating customised ropes from strong synthetic fibres like UHMWPE, ensuring high performance and safety. With customisation options tailored to specific lifting needs, including various coating options, iRopes delivers unparalleled quality and reliability. For wholesale customers and businesses in developed countries, iRopes offers comprehensive OEM and ODM services, making them an ideal partner for lifting sling needs.

Contact Us for Your Custom Lifting Sling

Fill in the inquiry form above to reach out to iRopes and customise the best rope for lifting heavy loads to suit your specific requirements. Our experts are ready to assist you with tailored solutions that enhance your lifting operations.