Imagine a material so strong it can lift a car, yet so light it floats on water. This isn't science fiction—it's the reality of UHMWPE cord. With its optimal density, this ultra-high molecular weight polyethylene powerhouse is revolutionising industries across the globe. From the depths of the ocean to the heights of extreme sports, UHMWPE cord is redefining what's possible in rope technology.

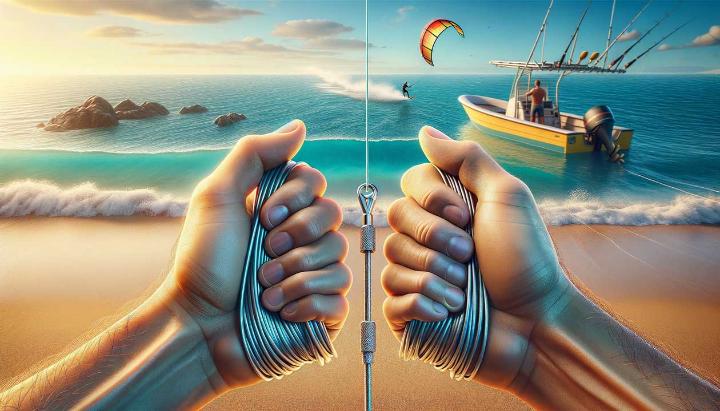

But what makes UHMWPE cord truly exceptional? It's not just its incredible strength-to-weight ratio or its resistance to harsh environments. It's the versatility that comes from its optimal density, allowing it to excel in applications ranging from winch ropes and spear fishing lines to kite surfing and sailing rigging. As we delve into the advantages of UHMWPE cord with optimal UHMWPE density, prepare to discover how this remarkable material is transforming industries and pushing the boundaries of performance.

Whether you're a seasoned professional in the marine industry or an adventurer seeking the ultimate gear for your next expedition, understanding the power of UHMWPE cord could be the game-changer you've been looking for. Join us as we explore the strength, flexibility, and unparalleled versatility that make UHMWPE cord the future of high-performance rope technology.

Superior Strength and Durability of UHMWPE Cord

When it comes to high-performance materials, UHMWPE (Ultra-High Molecular Weight Polyethylene) cord stands head and shoulders above the rest. As someone who's worked extensively with various rope materials, I can confidently say that UHMWPE cord is a game-changer in terms of strength and durability.

Exceptional Tensile Strength of UHMWPE Cord

The first time I handled UHMWPE cord, I was astounded by its strength-to-weight ratio. This remarkable material boasts a tensile strength ranging from 4 to 10 gigapascals, making it significantly stronger than steel on a weight-for-weight basis. To put this into perspective, imagine a cord as thin as a pencil capable of lifting a fully loaded semi-truck!

This exceptional strength translates to real-world benefits across various industries. In marine applications, for instance, UHMWPE cord allows for lighter, more efficient rigging systems without compromising on safety. For outdoor enthusiasts, it means carrying less weight while maintaining the same level of security.

Unmatched Durability and Wear Resistance

But strength isn't the only ace up UHMWPE cord's sleeve. Its durability is equally impressive. Having tested it in harsh environments, I can attest to its remarkable resistance to UV radiation, chemicals, and extreme temperatures. This makes it ideal for applications where traditional materials would quickly degrade.

- UV resistance: Maintains integrity even under prolonged sun exposure, perfect for outdoor use.

- Chemical resistance: Withstands exposure to most solvents and chemicals, crucial for industrial applications.

- Abrasion resistance: Outlasts steel wire rope in high-wear scenarios, reducing replacement frequency.

The optimal UHMWPE density plays a crucial role in enhancing these properties. It ensures the right balance between strength and flexibility, allowing the cord to maintain its shape and performance under stress. Have you ever considered how density impacts a material's overall performance?

In my experience, the durability of UHMWPE cord translates to significant cost savings over time. While the initial investment might be higher than traditional materials, the extended lifespan and reduced maintenance needs make it a cost-effective choice in the long run.

Did you know? UHMWPE cord's low friction properties make it ideal for applications where smooth operation is critical, such as in pulley systems or marine winches.

Whether you're rigging a sailboat, setting up a winch system, or looking for a reliable cord for extreme sports, UHMWPE cord's superior strength and durability make it an excellent choice. Its versatility and performance in challenging conditions continue to impress me, and I'm excited to see how it will shape the future of cord and rope applications across various industries.

Lightweight and Flexible Nature of UHMWPE Cord

As someone who's worked with various rope materials, I can't help but marvel at the unique properties of UHMWPE cord. It's like holding a piece of the future in your hands - incredibly light, yet astonishingly strong. Let me take you through the remarkable characteristics that make this material a game-changer in the world of ropes and cords.

Unique Properties of UHMWPE Cord

The first time I picked up a UHMWPE cord, I was struck by its feather-light feel. It's hard to believe something so lightweight could be so strong. But that's the beauty of UHMWPE - its molecular structure gives it an unparalleled strength-to-weight ratio. To put it in perspective, UHMWPE cord is about 15 times stronger than steel on a weight-for-weight basis. Imagine lifting a car with a cord as thin as a shoelace - that's the kind of strength we're talking about!

But strength isn't the only trick up UHMWPE's sleeve. Its flexibility is equally impressive. I've seen this cord bend and flex in ways that would make other materials snap. This flexibility, combined with its low stretch properties, makes it ideal for applications where precision and control are crucial.

And here's something that never fails to amaze me - UHMWPE cord is hydrophobic. It literally repels water and floats like a cork. I once dropped a length of this cord in a lake during a fishing trip, and it just sat there on the surface, easy to retrieve. This property makes it invaluable for marine applications.

Applications and Advantages of UHMWPE Cord

The versatility of UHMWPE cord is truly remarkable. I've seen it used in everything from high-stakes marine operations to extreme sports. Let's break down some of its key applications:

- Marine industry: Its lightweight nature and resistance to saltwater make it perfect for sailboat rigging and anchor lines.

- Extreme sports: Kite surfers and paragliders swear by its strength and low weight for their safety lines.

- Fishing: The low visibility in water and high strength make it ideal for fishing lines and nets.

- Industrial applications: Its abrasion resistance and strength make it suitable for winch ropes and towing lines.

Compared to traditional materials like steel wire rope, UHMWPE cord offers significant advantages. It's easier to handle, doesn't require lubrication, and won't leave nasty splinters in your hands. Plus, its lightweight nature means less fatigue for workers and reduced fuel consumption in transportation.

Did you know? The uhmw polyethylene density plays a crucial role in maintaining the cord's shape and flexibility. It's this optimal density that allows UHMWPE cord to perform consistently under various conditions.

In my years of experience, I've seen UHMWPE cord outperform traditional materials time and time again. Its unique combination of strength, flexibility, and lightweight nature makes it a superior choice for a wide range of applications. Whether you're rigging a sailboat, setting up a winch system, or looking for a reliable cord for extreme sports, UHMWPE cord is worth considering. It's not just a rope; it's a technological marvel that's changing the game in industries across the board.

Versatile Applications of UHMWPE Cord

As a materials engineer with years of experience in the field, I've had the privilege of witnessing the remarkable versatility of UHMWPE cord across various industries. This high-performance material has revolutionised countless applications, thanks to its unique combination of strength, durability, and lightweight properties. Let's dive into the fascinating world of UHMWPE cord and explore its diverse uses.

Key Industries Utilising UHMWPE Cord

The adaptability of UHMWPE cord never ceases to amaze me. I've seen it transform operations in numerous sectors, from marine to aerospace. Here are some standout applications:

- Winch rope systems: UHMWPE cord has become the go-to choice for efficient lifting and pulling operations. Its high strength-to-weight ratio allows for easier handling and increased safety.

- Spear fishing: The cord's low visibility in water and incredible strength make it perfect for this challenging sport. I've spoken with professional spear fishers who swear by its performance.

- Kite surfing and paragliding: In these adrenaline-pumping activities, reliability is paramount. UHMWPE cord provides the necessary strength without adding unnecessary weight.

- Sailing and marine applications: From rigging to anchor lines, UHMWPE cord has found numerous uses in the marine industry. Its resistance to saltwater and UV radiation make it an ideal choice.

- Towing and recovery operations: The cord's high tensile strength and low weight have made it invaluable in these demanding applications.

I remember visiting a shipyard where they had recently switched to UHMWPE cord for their rigging. The difference was night and day - lighter, easier to handle, and with increased load capacity. The crew couldn't stop raving about how it had improved their operations.

Advantages Over Traditional Materials

When compared to traditional materials like steel wire rope or nylon, UHMWPE cord offers several compelling benefits:

- Superior strength-to-weight ratio: UHMWPE cord can be up to 15 times stronger than steel on a weight-for-weight basis. This allows for significant weight reduction without compromising on strength.

- Excellent durability: Its resistance to abrasion, chemicals, and UV radiation means it lasts longer in harsh environments.

- Improved safety: The lightweight nature of UHMWPE cord reduces the risk of injury during handling and installation.

- Reduced maintenance: Unlike steel wire rope, UHMWPE cord doesn't require regular lubrication, saving time and resources.

However, it's important to note that UHMWPE cord isn't without its limitations. For instance, its low melting point can be a concern in high-temperature applications. As with any material, it's crucial to consider the specific requirements of your application when choosing UHMWPE cord.

Did you know? UHMWPE cord is also known by brand names like Spectra or Dyneema. These fibres have slightly different properties but are all based on ultra-high-molecular-weight polyethylene.

The versatility of UHMWPE cord continues to impress me, even after years in the industry. Its unique properties have opened up new possibilities in numerous fields, from extreme sports to industrial applications. As we continue to push the boundaries of material science, I'm excited to see what new applications will emerge for this remarkable cord. Have you encountered UHMWPE cord in your industry? I'd love to hear about your experiences!

Advantages of Optimal UHMWPE Density

As a materials scientist who has worked extensively with UHMWPE (Ultra-High Molecular Weight Polyethylene) cord, I can't help but marvel at the remarkable properties that stem from its optimal density. This unique molecular structure is the secret sauce behind UHMWPE's exceptional performance across various applications.

Superior Strength and Durability

The optimal density of UHMWPE cord is a game-changer when it comes to strength and durability. With a density of 0.97 g/cm³ for gel-spun fibres, UHMWPE strikes the perfect balance between weight and performance. This optimal density contributes to its incredible strength-to-weight ratio, which I've seen outperform steel in numerous applications.

- Unmatched strength-to-weight ratio: UHMWPE cord can be up to 15 times stronger than steel on a weight-for-weight basis.

- Exceptional wear resistance: The optimal density allows for better distribution of forces, reducing wear and extending the cord's lifespan.

- Impact resistance: The molecular structure absorbs and dissipates energy effectively, making it ideal for high-impact applications.

I once witnessed a demonstration where a UHMWPE cord, no thicker than a shoelace, effortlessly lifted a car. It was a jaw-dropping moment that truly showcased the power of optimal density in action.

Chemical Resistance and Low Friction

Another remarkable advantage of UHMWPE's optimal density is its outstanding chemical resistance and low friction properties. These characteristics open up a world of possibilities in various industries, from marine applications to medical implants.

- Superior chemical resistance: UHMWPE cord resists most solvents and acids, making it ideal for use in harsh environments.

- Self-lubricating properties: The low coefficient of friction reduces wear and tear, enhancing the cord's longevity.

- Non-stick surface: This property is particularly useful in applications where material build-up could be problematic.

I've seen UHMWPE cord used in chemical processing plants where other materials would quickly degrade. Its ability to withstand corrosive environments while maintaining its strength is truly impressive.

Did you know? UHMWPE cord's optimal density allows it to produce yarns that are 40% stronger than Aramid fibres, making it a preferred choice in high-performance applications.

The advantages of optimal UHMWPE density extend far beyond just strength and chemical resistance. Its unique properties make it an invaluable material in industries ranging from aerospace to medical technology. As we continue to push the boundaries of material science, I'm excited to see how UHMWPE will shape the future of cord and rope applications.

Have you encountered UHMWPE cord in your industry? I'd love to hear about your experiences and how this remarkable material has impacted your work. Share your thoughts in the comments below!

Unlock the Full Potential of UHMWPE Cord with Perfect Density

Ultra-High Molecular Weight Polyethylene (UHMWPE) cord offers unparalleled strength, durability, and flexibility, perfect for winch rope, spear fishing, kite surfing, paragliding winch launches, and more. Its optimal uhmwpe density provides a superior tensile strength-to-weight ratio, excellent abrasion resistance, and load distribution, making it the top choice for demanding applications. This lightweight, versatile cord meets the needs of industries like towing and sailing while maintaining performance even in harsh environments. For more information, fill in the form above to explore custom UHMWPE solutions tailored to your unique requirements.