Have you ever wondered what stands between a colossal tug boat and a maritime disaster? The answer lies in the quality and type of the tug boat rope. In the world of tug boats, ropes play an unsung yet essential role in ensuring safe towing and mooring operations under the harshest conditions. Selecting the right rope material is crucial not just for performance but also for safety and longevity.

Tug boat ropes face unique challenges due to their demanding operational environments. From resisting fierce currents to enduring prolonged exposure to saltwater, these ropes must be exceptionally strong and durable. But what are the best materials for achieving maximum durability in tug boat ropes? Finding the right material can make a significant difference in performance and cost-effectiveness.

This blog post delves into the 5 best tug boat rope materials, offering insights on their unique characteristics and applications. We'll explore why nylon, polyester, polypropylene, HMPE, and wire rope stand out among the myriad options. We'll also introduce you to iRopes' cutting-edge yacht ropes, engineered to meet the highest standards of quality and customized for your specific nautical needs. Continue reading to discover which rope material could be the game-changer for your tug boat operations and learn why iRopes is the ultimate choice for high-quality ropes.

Understanding Tug Boat Ropes: Characteristics and Applications

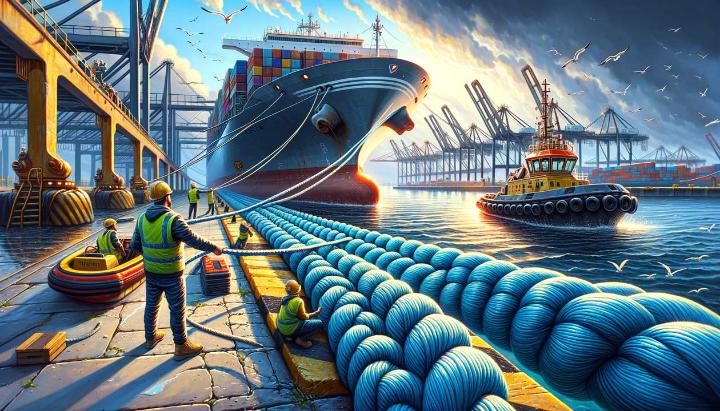

Tug boat ropes are the unsung heroes of maritime operations, playing a crucial role in ensuring the safe and efficient maneuvering of vessels in harbors, ports, and open waters. These specialized ropes are designed to withstand immense loads and harsh environmental conditions, making their selection a critical decision for any tugboat crew.

Exploring the Key Characteristics of Tug Boat Ropes

Imagine you're out on the open sea, the salty breeze whipping against your face as you guide a massive cargo ship into port. The success of this delicate operation hinges on the strength and reliability of your tug boat ropes. These ropes must possess exceptional strength to withstand the tremendous forces involved in towing and mooring operations. A single break could have catastrophic consequences.

But strength isn't the only essential characteristic. Tug boat ropes also require a degree of elasticity to absorb sudden shocks and jerks, preventing snap-backs that could endanger the crew. Moreover, they must exhibit excellent abrasion resistance to withstand the constant chafing against rough surfaces, ensuring a long service life.

Lastly, handling characteristics play a vital role in the smooth operation of tug boat maneuvers. Ropes that are too stiff or too slippery can make it challenging for the crew to control, potentially leading to dangerous situations.

Common Applications of Tug Boat Ropes

Tug boat ropes are indispensable in a wide range of maritime operations, each with its unique set of requirements and challenges. One of the most common applications is towing vessels, where these ropes must withstand tremendous loads and maintain their integrity over long distances.

Another critical use is securing ships to docks, where the ropes must be strong enough to hold large vessels in place while also being flexible enough to accommodate tidal movements and changes in weather conditions. Additionally, tug boat ropes play a vital role in assisting in maneuvering operations, allowing tugboats to precisely guide and position larger vessels in confined spaces.

Whether you're a seasoned mariner or a land-lover captivated by the maritime world, understanding the characteristics and applications of tug boat ropes is essential for appreciating the intricate dance of tugboats and their cargo on the high seas.

Top 5 Durable Materials for Tug Boat Ropes

When it comes to the rugged world of tug boat operations, durability is paramount. These hardworking vessels face unrelenting challenges, from battling fierce currents to navigating treacherous weather conditions. The ropes they rely on must be up to the task, capable of withstanding immense loads and harsh environments without compromising safety or performance.

Among the vast array of rope materials available, a select few stand out as the champions of durability for tug boat applications. Let's dive into the top five materials that offer the ultimate combination of strength, resilience, and longevity.

Nylon - The Stretch and Strength Champion

Nylon ropes have long been a favorite among mariners, and for good reason. With an exceptional strength-to-weight ratio and remarkable elasticity, nylon is the ultimate workhorse for tug boat operations. These ropes can withstand tremendous loads without sacrificing flexibility, making them ideal for docking, mooring, and anchoring maneuvers.

One of nylon's greatest assets is its ability to stretch and recover, allowing it to absorb sudden shocks and jerks that would easily snap a less elastic material. This resilience is invaluable when dealing with the unpredictable forces of nature on the open water.

Nylon ropes are the unsung heroes, offering a perfect blend of strength and flexibility.

Additionally, nylon's resistance to abrasion, sunlight, and most chemicals ensures a long service life, even in the harshest marine environments.

Polyester - Abrasion and UV Resistant

When it comes to sheer durability, polyester ropes are in a league of their own. These synthetic marvels are highly resistant to water, UV radiation, and abrasions, making them an excellent choice for tug boat operations that demand uncompromising performance.

Polyester's high tensile strength and dimensional stability make it a reliable choice for applications requiring minimal stretch and maximum load-bearing capacity. Whether you're towing a massive cargo vessel or securing a ship to the dock, polyester ropes can handle the strain with ease.

But what truly sets polyester apart is its exceptional resistance to the elements. These ropes can withstand prolonged exposure to harsh sunlight and saltwater without succumbing to degradation, ensuring a longer lifespan and reduced maintenance costs.

Dyneema - Ultra High-Strength Synthetic Fiber

When it comes to sheer strength-to-weight ratio, Dyneema (also known as UHMWPE or Ultra-High Molecular Weight Polyethylene) reigns supreme. This cutting-edge synthetic fiber is the world's strongest, offering a level of performance that is unmatched by traditional rope materials.

Dyneema ropes are incredibly lightweight yet incredibly strong, making them ideal for applications where weight is a critical factor, such as towing lines or 5/8" boat ropes. Their exceptional strength allows them to handle enormous loads with ease, while their lightweight nature reduces the overall weight burden on the tug boat.

- Exceptional strength

- Lightweight construction

- Resistance to abrasion, chemicals, and moisture

Dyneema's resistance to abrasion, chemicals, and moisture further enhances its durability, making it a versatile choice for a wide range of tug boat applications, from mooring lines to towing operations.

Vectran - Heat and Abrasion Resistant Hybrid

When it comes to high-performance ropes, Vectran is a true standout. This hybrid material combines the benefits of polyester with other fibers, resulting in a rope that is remarkably resistant to heat, abrasion, and cutting.

Vectran's unique properties make it an excellent choice for high-load applications, where its superior grip and durability shine. These ropes can withstand extreme temperatures and harsh abrasive environments, making them ideal for operations in challenging conditions.

Oftentimes, Vectran is blended with polyester or a polyester/Technora combination, creating a rope that offers the best of both worlds – exceptional strength and resistance to heat, abrasion, and cutting. This versatility makes Vectran a valuable asset in the tug boat industry, where reliability and longevity are paramount.

Polypropylene - Lightweight and Floating

While not the strongest material on this list, polypropylene ropes deserve recognition for their unique advantages. These lightweight and buoyant ropes are highly resistant to chemicals and solvents, making them a practical choice for certain marine applications.

Polypropylene's lightweight nature and buoyancy can be advantageous in situations where weight distribution or flotation is a concern. However, it's important to note that polypropylene ropes may not offer the same level of strength as synthetic fibers like nylon or polyester.

Nevertheless, for applications where moderate strength and buoyancy are desired, polypropylene ropes can be a cost-effective and practical solution, particularly for tasks such as mooring, docking, or securing lightweight vessels.

- Lightweight and buoyant

- Resistant to chemicals and solvents

- Cost-effective option for certain applications

While polypropylene may not be the first choice for heavy-duty tug boat operations, it can serve as a valuable complement to other rope materials, offering a unique set of advantages in the right circumstances.

Choosing the right rope material for your tug boat operations is a critical decision that can impact safety, performance, and cost-effectiveness. By understanding the strengths and limitations of each material, you can make an informed choice that meets the specific demands of your maritime operations.

At the end of the day, durability is the name of the game when it comes to tug boat ropes, and these top five materials – nylon, polyester, Dyneema, Vectran, and polypropylene – offer the ultimate combination of strength, resilience, and longevity to keep your vessels operating at peak performance, no matter the challenge.

Key Factors to Consider When Choosing Tug Boat Rope Material

As the tug boat industry tackles some of the most demanding maritime operations, selecting the right rope material is a critical decision that can significantly impact safety, performance, and cost-effectiveness. These hardworking vessels face unrelenting challenges, from battling fierce currents to navigating treacherous weather conditions, making the choice of rope material a vital consideration.

Imagine being tasked with towing a massive cargo ship through choppy waters, with the success of the operation resting on the strength and reliability of your tug boat ropes. Can you picture the strain and tension those ropes must endure? It's a scenario that underscores the importance of choosing a material that can withstand immense loads and harsh environments without compromising performance.

Material Properties and Performance

When it comes to tug boat ropes, different materials offer distinct advantages and trade-offs. Nylon and polyester are two popular choices, each boasting unique strengths that cater to specific operational requirements.

Nylon ropes are renowned for their exceptional strength-to-weight ratio and remarkable elasticity. These properties make them ideal for docking, mooring, and anchoring maneuvers, where the ability to absorb sudden shocks and jerks is crucial. However, nylon can be susceptible to degradation from UV exposure and chemicals, a factor that must be considered in marine environments.

On the other hand, polyester ropes shine in their resistance to UV radiation, saltwater, and abrasions. Their high tensile strength and dimensional stability make them a reliable choice for applications requiring minimal stretch and maximum load-bearing capacity, such as towing massive cargo vessels or securing ships to docks.

It's important to carefully consider the intended application and environmental conditions when selecting the appropriate rope material. For instance, if your operations involve prolonged exposure to harsh sunlight and saltwater, a polyester rope may be the more durable choice. Conversely, if you prioritize elasticity and shock absorption, nylon could be the better option.

Construction and Strength Characteristics

Beyond the material itself, the construction method and design of the rope play a crucial role in determining its overall performance. Double-braided ropes, for instance, are renowned for their exceptional strength, flexibility, and ease of handling, making them a popular choice for tug boat applications.

When selecting a tug boat rope, it's essential to evaluate critical strength characteristics like breaking force, elongation, and spliceability. These factors directly impact the rope's ability to withstand the immense loads and stresses associated with tug boat operations.

Have you ever considered the sheer horsepower of a tug boat and the forces it must contend with? Whether you're maneuvering a smaller vessel or a behemoth cargo ship, your rope's strength and construction must be meticulously matched to the task at hand. A miscalculation could have dire consequences, putting crew safety and valuable cargo at risk.

Expert Tip

When selecting a tug boat rope, consider the vessel's size, horsepower, and intended use. A larger, more powerful tug boat may require a rope with a higher breaking force and elongation to handle the increased loads safely.

By carefully evaluating the material properties, construction methods, and strength characteristics, you can make an informed decision that meets the specific demands of your tug boat operations. Remember, the right rope can mean the difference between a successful, safe mission and a potential disaster on the high seas.

Introducing iRopes' High-Quality Yacht Ropes

As the waves crash against your sleek yacht, the sails billow with the wind, propelling you forward on your maritime adventure. In these exhilarating moments, the integrity of your yacht's ropes becomes paramount. That's where iRopes shines – a trusted manufacturer of premium yacht ropes, expertly crafted to withstand the demands of the open waters.

With a deep understanding of the unique challenges faced by yachters, iRopes has dedicated itself to producing high-quality ropes that embody strength, resilience, and durability. From the meticulous selection of materials to the implementation of advanced construction techniques, every step of the manufacturing process is meticulously designed to ensure exceptional performance.

What Makes iRopes Yacht Ropes Superior?

At iRopes, we understand that every sailing adventure is unique, and our yacht ropes are designed to cater to a wide range of needs and preferences. Whether you're a seasoned racer seeking high-performance lines or a casual cruiser prioritizing durability and ease of use, our extensive product lineup has you covered.

Our yacht ropes are crafted from a meticulously curated selection of materials, including polyester, nylon. Each material offers its own distinct advantages, from exceptional strength-to-weight ratios to unparalleled resistance against UV radiation, saltwater, and abrasion.

But it's not just the materials that set our ropes apart; it's the construction methods that elevate their performance. We employ cutting-edge techniques like double-braiding and core-sheathing, ensuring optimal strength and flexibility for seamless handling and maneuverability on the water.

Additionally, our ropes feature specialized cover materials, such as Technora and Cordura, which provide unmatched abrasion resistance and superior grip – essential qualities for halyards, sheets, and control lines that endure relentless wear and tear.

At iRopes, we believe that every nautical adventure deserves ropes that are as exceptional as the journey itself.

Choosing the Right Rope for Your Yachting Needs

Whether you're setting sail for a thrilling regatta or embarking on a leisurely coastal cruise, selecting the right rope is crucial for a safe and enjoyable experience. At iRopes, we understand the nuances of different yachting activities and tailor our recommendations accordingly.

For racing enthusiasts, we offer lightweight yet ultra-strong ropes that can withstand the rigors of high-performance sailing, ensuring your lines remain taut and responsive even in the most demanding conditions. On the other hand, for those seeking a relaxing voyage, our durable and easy-to-maintain ropes provide peace of mind, allowing you to focus on savoring the breathtaking vistas and creating cherished memories.

Regardless of your yachting needs, our team of experts is dedicated to guiding you through the selection process, taking into account factors such as breaking strength, stretch, UV resistance, and compatibility with your boat's equipment. We believe that every customer deserves a personalized solution that perfectly aligns with their unique requirements.

Inquiry About Our Customised Tug Boat Ropes

Selecting the right tug boat rope material is essential for ensuring the durability and efficiency of maritime operations. Whether it's the superior elasticity of nylon, the UV resistance of polyester, the lightweight nature of polypropylene, the unparalleled strength of HMPE for 5/8 boat rope, or the robust durability of wire rope, understanding the characteristics of these materials can significantly impact your choice. iRopes offers high-quality, customizable yacht ropes that adhere to stringent international standards, catering to unique requirements with precision and expertise. Use the form above to inquire about our boat rope winch compatibility and bespoke solutions to enhance your operations.